YCW100 Integrated chiler

Description of Integrated chiler

>High energy efficiency ratio: Water-cooled units achieve an energy efficiency ratio approximately 30% higher than air-cooled units.

>Stable Performance: Water-cooled units feature low condensing temperatures and are less affected by ambient temperatures, ensuring stable system operation.

>No need for a machine room, saving floor space;

> No need for mechanical room construction; comes equipped with a cooling tower, cooling water pump, chilled water pump, and expansion tank for easy operation.

>Low initial investment.

Characteristics of Integrated chiler

Quick Installation

The refrigeration system and water system components are integrated into a single design and installed within the enclosure. This structure combines the chiller unit, cooling station equipment, and refrigeration plant into one compact unit. It features an aesthetically pleasing appearance while also reducing plant investment costs. It can be directly placed on rooftops or other open areas. Simply connect the main power supply and the chilled water system inlet/outlet pipes to begin operation.

Smart Operation

Intelligent Control: The microcomputer enables fully automated interlinked operation of the chiller unit, water pumps, cooling tower fans, and capacity-regulating solenoid valves. The unit features comprehensive safety protection devices: high-pressure, low-pressure, discharge superheat, compressor motor overheat, overcurrent, reverse phase, freeze protection, emergency stop switch, safety valve, and water failure. Management functions such as remote data acquisition, operational monitoring and control, and fault diagnosis are achieved via LAN or the Internet.

Reliable And Durable

The outer frame utilizes a molybdenum-zinc-coated steel structure with a galvanized channel steel base frame, offering both structural integrity and aesthetic appeal. All frame structural components are bolted together without welding points to minimize corrosion. Unit piping connections employ specialized fittings, reducing welding and facilitating maintenance. The frame's sheet metal is sealed with specialized waterproof materials to ensure internal dryness.

Outstanding Performance

The unit employs industrial-grade server room exhaust fans, delivering exceptional heat dissipation performance. This overcomes the limitations of residential ventilation fans—low air pressure and insufficient airflow—ensuring timely removal of internal heat. This safeguards both the unit's operational environment and the surrounding workspace. Combining multiple advantages of traditional air conditioning units, it features air-cooled configuration, water-cooled efficiency, multi-split system flexibility, and intelligent control capabilities.

· PrFood processing workshops

· Cold stores and freezer rooms

· Cold chain logistics centres and distribution warehouses

· Pharmaceutical factories and cleanrooms

· Biological laboratories and sample repositories

· Flower preservation chambers

·Hotels, shopping malls, cinemas, restaurants, dining establishments, entertainment venues, offices

·Process cooling systems for chemical plants, pharmaceutical plants, electronics factories, etc.

| Model | YCW70 |

Cooling Water Water Flow Rate(t/h) |

30.0 |

|

Cooling capacity(kw) |

69.0 |

Cooling water Fan power × Number of units(KW) |

1.1X1 |

| Cooling capacity(kcal/h*104) | 5.9 |

Cooling Water Water Pump Power(KW) |

2.2 |

| Cooling capacity(USRT) | 19.7 |

Safety Protection |

High-pressure protector, low-pressure protector, exhaust temperature protector, safety valve, water flow switch, etc. |

| Power supply | 3N/380V/50HZ |

Total Power(KW) |

26.2 |

| Compressor rated current(A) | 41.4 |

Noise(dB(A)) |

65 |

| Compressor Output Power(KW) | 19.9 |

Refrigerant |

R22 |

| Compressor Type |

Semi-hermetic twin-screw compressor |

Refrigerant Charge(kg) |

22 |

| Compressor Start-Up Method |

25% load + star-delta voltage reduction start |

Length(mm) |

3800 |

|

Chilled Water Flow Rate(t/h) |

16.6 | Width(mm) | 2480 |

|

Chilled Water Pump Head(m) |

28.0 |

Height(mm) |

2550 |

|

Chilled Water Pump Power(KW) |

3.0 |

Net weight(kg) |

1770 |

|

Interface Specifications |

2-DN65 | Operating weight(kg) | 2750 |

1. What exactly is an "Integrated" Water-Cooled Chiller?

It is a skid-mounted system that combines the chiller, chilled water pump, cooling water pump, water tank, piping, valves, and control system into one pre-assembled unit.

2. How does this differ from a traditional chiller plant?

Traditional systems require separate sourcing and on-site installation of pumps, pipes, and controls. Our integrated unit is "plug-and-play," significantly reducing installation time and engineering complexity.

3. What are the main components included on the skid?

The skid includes the compressor (screw or scroll), shell-and-tube evaporator/condenser, circulation pumps, expansion tank, water flow switches, and the central control panel.

4. Does this unit require a cooling tower?

Yes, as a water-cooled system, it requires a connection to an external cooling tower (unless specified as an evaporative integrated model). We can supply a matching cooling tower upon request.

5. What are the primary applications for this unit?

It is ideal for plastic injection molding, electroplating, chemical processing, pharmaceutical manufacturing, HVAC for commercial buildings, and data center cooling.

6. Can this unit be installed outdoors?

Standard units are designed for indoor plant rooms (IP44). However, we offer IP55/IP65 weather-proof housing options for outdoor roof or ground installation.

7. What refrigerant options do you offer?

Standard units use R407C or R410A. We also offer eco-friendly options like R134a and low-GWP refrigerants like R1234ze upon request.

8. Is the unit factory tested?

Yes, every unit undergoes a full-load run test at our factory before shipment to ensure all hydraulic and electrical components function correctly.

9. What is the expected lifespan of the unit?

With proper maintenance, the design life is 15–20 years.

10. Do you offer explosion-proof models?

Yes, we can customize units with explosion-proof electrical components for hazardous environments (e.g., chemical plants).

11. What is the cooling capacity range available?

Our integrated series ranges from 10 tons (35 kW) up to 200 tons (700 kW) per single skid.

12. What type of compressors are used?

Smaller units typically use Scroll compressors (Danfoss/Copeland), while larger units use Semi-Hermetic Screw compressors (Hanbell/Bitzer).

13. Can the system handle variable loads?

Yes, screw compressor models feature stepless capacity control (25%-100%), and VFD (Variable Frequency Drive) options are available for precise load matching.

14. What is the standard chilled water outlet temperature?

The standard range is 5°C to 20°C. Low-temperature models (glycol required) can reach -5°C to -30°C.

15. What is the temperature stability accuracy?

Standard units maintain ±1°C. Precision models can achieve ±0.5°C or better.

16. What voltage supply is required?

Standard is 3-phase, 380V/50Hz. We can customize for 220V/60Hz, 440V/60Hz, or 480V/60Hz for different regions.

17. Are the pumps stainless steel?

Yes, the wetted parts of the integrated pumps are typically Stainless Steel 304 to prevent rust and corrosion.

18. What is the noise level of the unit?

Noise levels vary by size but generally range between 65 dB(A) and 80 dB(A). Sound-attenuating enclosures are available.

19. Does the unit use a shell-and-tube or plate heat exchanger?

We use Shell-and-Tube for condensers (better for water quality tolerance) and either Shell-and-Tube or Brazed Plate for evaporators, depending on the model size.

20. What is the Energy Efficiency Ratio (EER/COP)?

Our water-cooled units typically achieve a COP between 4.5 and 5.8, depending on operating conditions and compressor type.

21. How much floor space can I save compared to a traditional system?

You can save approximately 30–40% of floor space since pumps and valves are compactly arranged on the skid.

22. Do I need a special concrete foundation?

A flat, level concrete pad capable of supporting the unit's operating weight is sufficient. Anti-vibration pads are recommended.

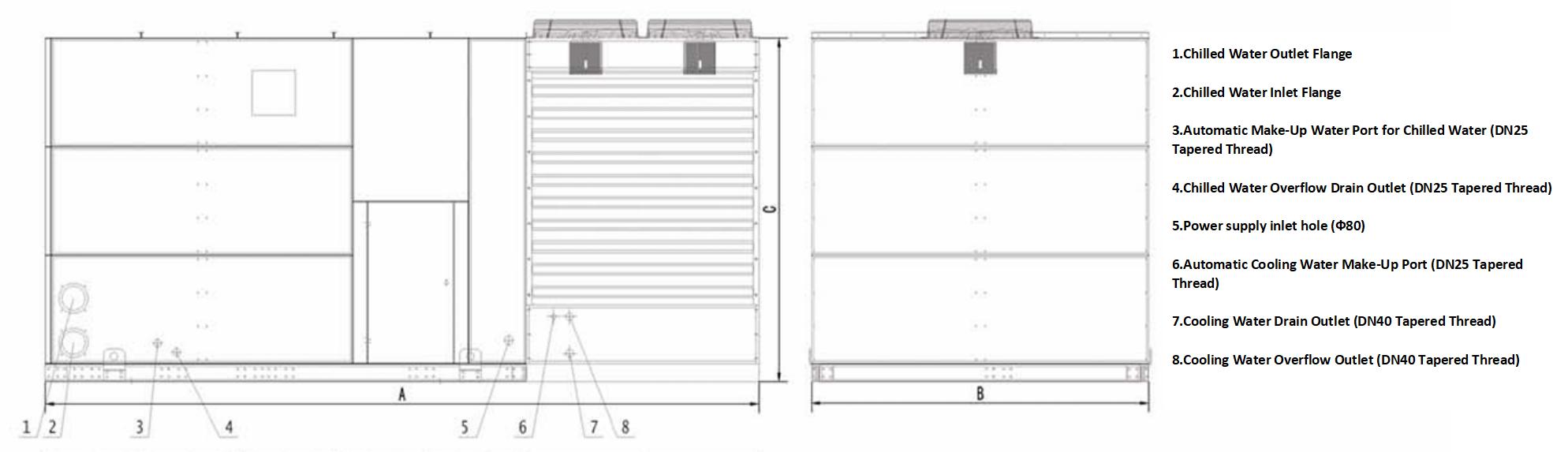

23. What piping connections need to be made on-site?

You only need to connect:

-

Chilled water supply & return.

-

Cooling tower water supply & return.

-

Make-up water line.

24. How is the unit transported?

It is shipped as a single crate/skid. It includes lifting lugs for crane lifting and a base frame suitable for forklifts.

25. Does the unit require a dedicated machine room?

No, because it is self-contained and quiet, it can often be placed near the production equipment, reducing piping runs.

26. What size are the water connections?

Connection sizes range from DN25 (1 inch) to DN200 (8 inches) depending on capacity. Flange or thread connections are available.

27. Do I need to install an external water tank?

The unit typically includes a buffer tank. However, for very large water volume systems, an external tank might still be beneficial.

28. How far can the cooling tower be from the unit?

The integrated pumps have a specific head pressure (e.g., 20m–30m). If the tower is very far or high, we may need to upgrade the pump on the skid.

29. Is a bypass valve included?

Yes, a manual or automatic bypass valve is often included to protect the evaporator from low flow.

30. Can I stack these units?

No, these units are not designed to be stacked vertically. They must be placed side-by-side.

31. What brand of PLC/Controller is used?

We standardly use Siemens, Punp, or Schneider PLC systems.

32. Is the interface user-friendly?

Yes, it features a 7-inch or 10-inch color touchscreen with multi-language support (English, Spanish, Chinese, etc.).

33. Can I connect this to my Building Management System (BMS)?

Yes, the controller supports Modbus RS485 communication protocol. BACnet is available as an option.

34. Does it have remote monitoring capabilities?

Yes, optional IoT modules allow you to monitor temperature, pressure, and alarms via a mobile app or web browser.

35. What happens if the power fails?

The unit has an auto-restart function. Once power is restored, it will resume the previous settings (customizable).

36. What safety protections are included?

High/low pressure, freeze protection, compressor overload, pump overload, phase sequence protection, and water flow loss protection.

37. Does it have a "Soft Start" feature?

Soft starters are standard on larger screw compressor models to reduce in-rush current.

38. Can I control the external cooling tower fan from this unit?

Yes, an interlock terminal is provided to start/stop the cooling tower fan automatically when the chiller runs.

39. How are alarms displayed?

Alarms are displayed on the screen with a specific error code and timestamp. An audible buzzer also sounds.

40. Is the control panel dust-proof?

Yes, the electrical cabinet is sealed and ventilated, typically rated IP54 or higher.

41. How often should I change the compressor oil?

We recommend an oil analysis annually. Typically, oil is changed every 10,000 running hours or as indicated by the analysis.

42. How do I clean the condenser?

Since we use shell-and-tube condensers, the end caps can be removed to mechanically brush clean the copper tubes.

43. Is a water strainer included?

Yes, Y-strainers are installed at the pump inlets to prevent debris from entering the system.

44. What happens if the water freezes?

The unit has a built-in anti-freeze thermostat. If the temperature drops too low, the unit shuts down and triggers an alarm. Glycol is recommended for low-ambient environments.

45. Are spare parts easily available?

We use globally recognized component brands (Schneider, Danfoss, Siemens), so parts can be sourced locally in most countries. We also sell spare part kits.

46. How do I check the refrigerant level?

A sight glass is installed on the liquid line. Clear liquid indicates a full charge; bubbles indicate low charge.

47. Does the system require water treatment?

Yes, because it uses a cooling tower, the condenser water loop must be treated to prevent scaling and biological growth.

48. Can the pumps be isolated for service without draining the system?

Yes, isolation valves are installed before and after the pumps for easy maintenance.

49. Is there a warranty?

Standard warranty is 12 months from commissioning or 18 months from shipment, whichever comes first. Extended warranties are available.

50. Do you provide technical support for installation?

We provide detailed manuals and video guides. We can also send an engineer on-site for commissioning (additional cost applies).

51. What is the typical lead time?

Standard voltage units usually ship in 15–20 working days. Custom voltage or explosion-proof units take 30–40 days.

52. Can you put my company logo on the unit (OEM)?

Yes, we offer OEM services including custom colors and logo placement on the casing and startup screen.

53. How is the unit packed for export?

It is wrapped in plastic film and secured inside a fumigation-free plywood crate or loaded directly into a container with strapping.

54. What are the payment terms?

Typically 30% deposit via T/T, and 70% balance before shipment. L/C is also accepted for large orders.

55. Where can I download the 3D drawings or CAD files?

Please contact our sales team with your specific model requirement, and we will email the STP/DWG files within 24 hours.