1. Product Overview

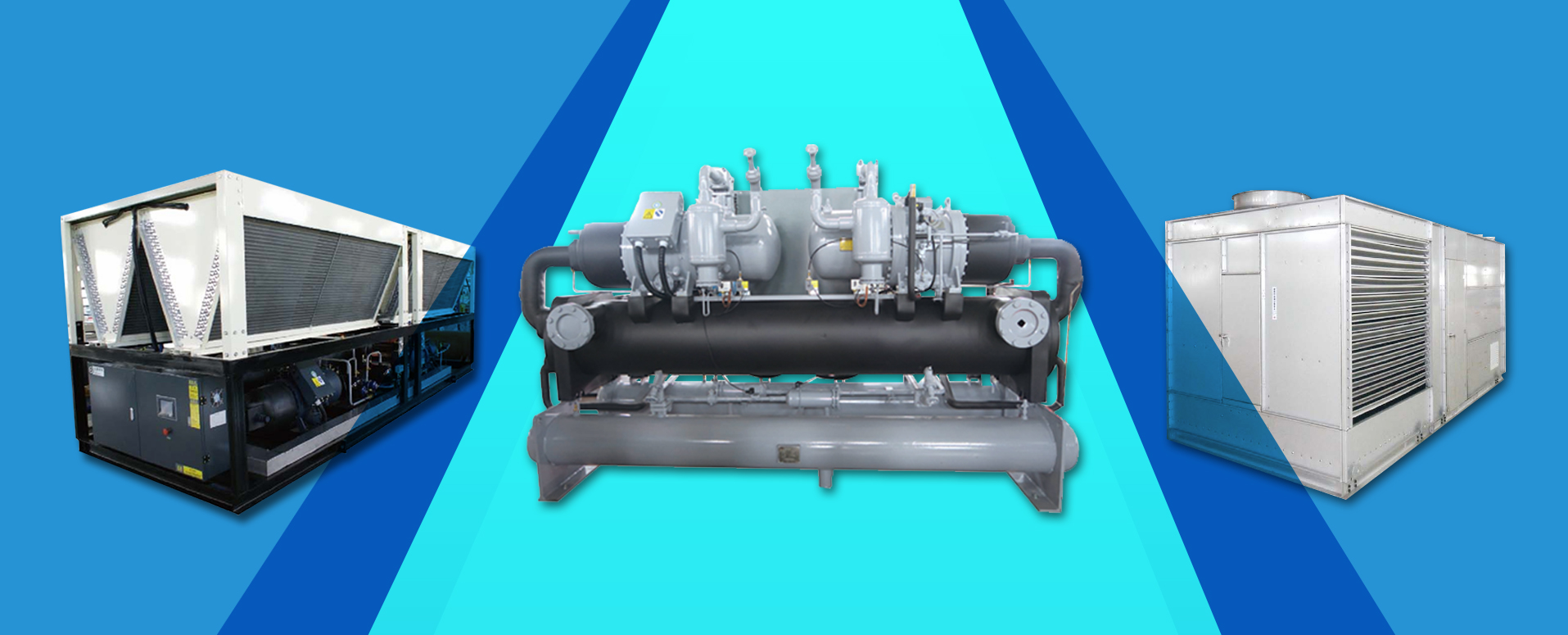

The air-cooled screw heat pump unit serves as an integrated energy station combining high-efficiency cooling with robust heating capabilities. This series eliminates the need for cooling towers, chilled water pumps, and dedicated plant rooms, allowing direct installation on rooftops or outdoor ground surfaces. It represents the preferred solution for modern green buildings and industrial temperature control.

Employing high-efficiency semi-hermetic screw compressors combined with advanced air-side heat exchange technology, it delivers constant chilled water in summer while operating as a high-efficiency heat pump in winter. It provides domestic hot water or heating water at 45°C-55°C, perfectly replacing traditional ‘chiller + boiler’ systems and significantly reducing initial investment and operational costs.

2. Key Specifications

Functional Modes: Cooling / Heating / Year-round Domestic Hot Water

Cooling Capacity Range: 100kW - 1800kW

Heating Capacity Range: 110kW - 1900kW

Temperature Range:

Cooling Outlet Water: 5°C ~ 15°C (Standard 7°C)

Heating Outlet Water Temperature: 40°C ~ 50°C (Maximum 55°C)

Ambient Operating Temperature: Cooling 15°C~48°C / Heating -15°C~25°C

Refrigerant: Environmentally Friendly R410A, R134a, R407C

Heat exchanger configuration: V-type or W-type air-side heat exchanger (optimised airflow organisation)

3. Core Technical Features (Features & Advantages)

3.1 Dual-function heating and cooling, multi-purpose operation

Dual-mode operation: A single unit addresses both winter and summer requirements. Utilising four-way valve reversing technology, it enables rapid switching between refrigeration and heat pump cycles.

No Cooling Water System Required: Unlike water-cooled units, this system utilises ambient air for heat dissipation/absorption, eliminating the need for cooling towers. This conserves water resources while preventing scaling and Legionella risks associated with cooling water systems.

3.2 Screw Core Optimised for Heat Pump Operation

Heat Pump Dedicated Compressor: Internally reinforced for high pressure differential and heavy load heating conditions, ensuring stable compressor operation in low winter temperatures.

Stepless Capacity Control: Employing sliding valve stepless modulation technology (25%-100%), it precisely adjusts output energy according to terminal load variations, achieving water temperature control accuracy of ±0.5°C.

3.3 Intelligent Defrosting Technology

The primary challenge in winter heating lies in outdoor coil icing. This unit abandons conventional timed defrosting, employing intelligent pressure differential and temperature differential sensing logic:

Defrost only when frost is present: Precisely judges frost thickness, initiating the defrost cycle only when necessary.

Rapid reheating: Reduces defrosting time (typically <3 minutes), minimising water temperature fluctuations during defrosting to ensure heating comfort.

3.4 High-Efficiency Fin Heat Exchanger

Hydrophilic Aluminium Foil: Blue or gold hydrophilic aluminium foil fins effectively prevent water bridge formation, delay frost accumulation, and offer superior corrosion resistance.

V-Shaped Structure: Unique V-shaped air-side design increases air intake area, improves airflow distribution, enhances heat exchange efficiency, and reduces fan noise.

Envie Sua Mensagem

Sinta-se à vontade para entrar em contato conosco. Estamos prontos para ajudá-lo.