Fruits And Vegetables Cold Room Temperatures

Pre-Cooling Cold Rooms

Chilled Storage Cold Rooms

Chilled Storage Cold Rooms

Controlled Atmosphere (CA) Cold Rooms

Controlled Atmosphere (CA) Cold Rooms

>Long-term storage with regulated gas composition (O₂ and CO₂ levels).

>0°C to 5°C (32°F to 41°F)

>Extend storage life by slowing respiration & ripening.

>Ideal for apples, kiwifruit, and other climacteric fruits.

Frozen Storage Rooms

Frozen Storage Rooms

Ripening Cold Rooms

Ripening Cold Rooms

Cold Room Types for Fruits and Vegetables

Comprehensive Guide to Fruit & Vegetable Cold Storage: Frequently Asked Questions

Comprehensive Guide to Fruit & Vegetable Cold Storage: Frequently Asked Questions

1. Why do fruits and vegetables need cold storage?

Unlike processed foods, harvested fruits and vegetables are living organisms. They continue to undergo biological processes, primarily respiration and transpiration.

-

Respiration: The produce takes in oxygen and breaks down stored carbohydrates (sugars/starches) to release energy, carbon dioxide, and heat. This process leads to aging and decay. Cooling slows down respiration significantly.

-

Transpiration: The loss of water vapor. Since the produce is cut off from the root system, it cannot replace lost water. Cooling reduces the rate of evaporation, keeping the produce firm.

2. What is "Field Heat" and why must it be removed?

Field heat is the thermal energy the produce holds when harvested, often absorbed from the sun and high ambient air temperatures.

-

Impact: If field heat is not removed quickly, it accelerates ripening and bacterial growth.

-

Vital Heat: As produce respires, it generates its own heat (Vital Heat). If field heat isn't removed, the vital heat adds to it, creating a "heat trap" inside the packaging that can rot the product from the inside out.

3. What is the difference between Climacteric and Non-Climacteric fruits?

This is a critical distinction for storage management.

-

Climacteric Fruits: These can ripen after harvest. They produce a burst of ethylene gas and their respiration rate spikes during ripening. (Examples: Bananas, Avocados, Tomatoes, Apples, Pears, Peaches).

-

Non-Climacteric Fruits: These do not ripen or improve in flavor after harvest; they only soften or rot. They must be harvested at peak maturity. (Examples: Grapes, Citrus, Berries, Pineapples, Watermelons).

4. What is the Q10 Coefficient in cold storage?

The Q10 coefficient is a measure of the rate of change of a biological system as a consequence of increasing the temperature by 10°C.

-

Rule of Thumb: For fresh produce, the metabolic rate (aging) increases by a factor of 2 to 3 for every 10°C rise. Therefore, keeping broccoli at 20°C makes it rot roughly 4 to 6 times faster than keeping it at 0°C.

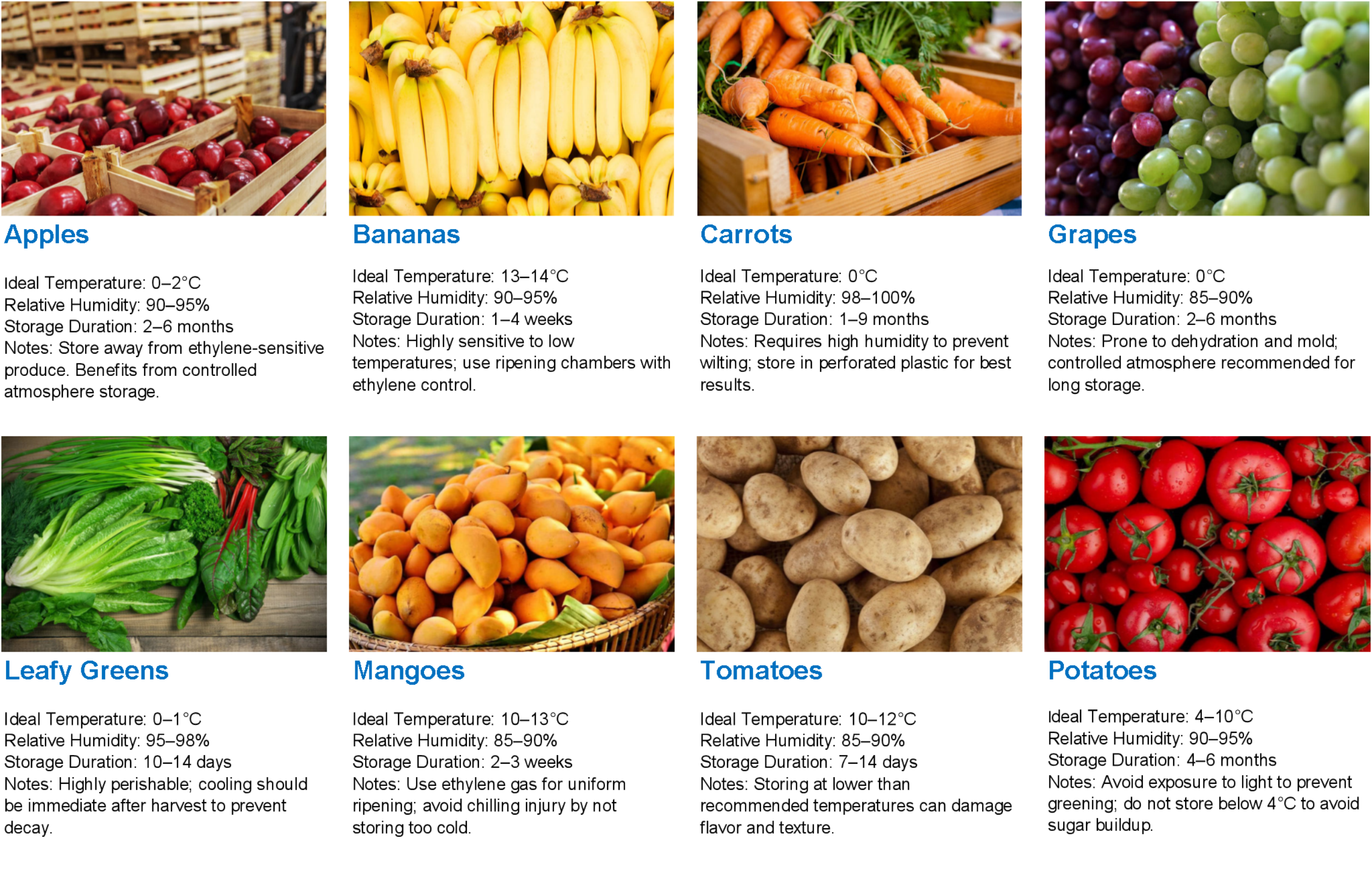

For most crops originating in temperate climates (Leafy greens, Apples, Pears, Carrots, Broccoli, Berries), the goal is to store them as close to 0°C (32°F) as possible without freezing. The target is usually 0°C to 2°C.

6. What is "Chilling Injury" (CI)?

Chilling Injury is physiological damage that occurs at temperatures above freezing but below a critical threshold (usually below 10°C-13°C). It primarily affects crops of Tropical or Sub-tropical origin.

-

Symptoms: Pitting (sunken spots), discoloration (browning/blackening), failure to ripen, and watery flesh.

-

Sensitive Crops: Bananas, Mangoes, Cucumbers, Eggplants, Green Beans, Tomatoes, Zucchini.

-

Storage Rule: These items should generally be stored between 10°C and 14°C (50°F - 57°F).

7. Why shouldn't I store Tomatoes in a standard 4°C fridge?

Tomatoes are highly susceptible to chilling injury. Below 10°C, the enzyme responsible for flavor generation stops working, and the texture becomes "mealy" or floury. Tomatoes should be stored at 12°C - 15°C or at room temperature.

8. What is the actual freezing point of fruits and vegetables?

It is not 0°C. Because cell sap contains dissolved sugars, salts, and amino acids, the freezing point is depressed.

-

Typical Range: Most fruits and vegetables freeze between -1.5°C and -2.5°C.

-

Safety Margin: This is why commercial cold rooms are set to 0°C or 1°C, to provide a safety buffer against accidental freezing.

9. Can temperature fluctuations damage produce?

Yes. If the temperature fluctuates significantly (e.g., door left open), two things happen:

-

Respiration Spikes: The produce wakes up and burns sugar reserves.

-

Condensation: Warm air holds more moisture than cold air. When the air cools down again, water condenses on the cold fruit. Wet surfaces are the primary trigger for mold growth (Botrytis).

10. What is Ethylene ($C_2H_4$)?

Ethylene is a natural plant hormone in the form of an odorless, colorless gas. It regulates ripening and aging (senescence).

11. What is the "Ethylene Mixing Rule"?

You must never store Ethylene Producers with Ethylene Sensitive crops.

-

Producers: Apples, Pears, Bananas (ripening), Cantaloupes, Avocados, Tomatoes.

-

Sensitive: Lettuce (gets russet spotting), Carrots (become bitter/isocoumarin), Cucumbers (turn yellow), Broccoli (florets yellow/fall off), Flowers.

-

Scenario: If you store apples next to lettuce, the lettuce will be ruined within days.

12. How can I remove Ethylene from a cold store?

-

Ventilation: Introducing fresh outside air (if temperature permits) to flush out the gas.

-

Scrubbers: Machines that filter air through potassium permanganate (which turns from purple to brown as it absorbs ethylene).

-

Ozone ($O_3$): Ozone generators can oxidize ethylene, breaking it down into CO2 and water.

13. Are there treatments to block Ethylene?

Yes. 1-MCP (1-Methylcyclopropene) is a commercial treatment used commonly on apples and pears (brand name SmartFresh). It binds to the ethylene receptors in the fruit, essentially "blinding" the fruit to the presence of ethylene, keeping it crunchy for months.

14. What is the ideal Relative Humidity for most produce?

For most fruits and vegetables (especially leafy greens), the ideal RH is 90% to 95%.

-

Reason: Produce is 80-95% water. The air in a cold room naturally wants to be dry. If the humidity is low, the air sucks moisture out of the produce (Vapor Pressure Deficit), causing wilting and shriveling.

15. Which crops require LOW humidity?

-

Onions and Garlic: Require 65% - 70% RH. High humidity causes root growth and mold (neck rot).

-

Pumpkins and Winter Squash: Require 50% - 70% RH.

-

Ginger: Requires moderate humidity to prevent mold but not dry out.

-

Warning: Never store onions in the same room as leafy greens, not just because of smell, but because the humidity requirements are opposites.

16. How do I increase humidity in a cold room?

-

Humidifiers: Use ultrasonic humidifiers or "fogging" nozzles.

-

Wet Floors: In basic setups, wetting the floor can help, but it risks sanitation issues.

-

Coil Design: Using evaporators with a large surface area and a low "TD" (Temperature Difference between the coil and the room) naturally maintains higher humidity.

17. How do I store Leafy Greens (Lettuce, Spinach, Kale)?

-

Temp: 0°C - 1°C.

-

RH: 95% - 100%.

-

Key: Rapid cooling is essential (Vacuum cooling is best). They have a very large surface area relative to weight, so they dehydrate in hours if not kept humid.

18. What are the storage requirements for Potatoes?

Potatoes are complex and depend on the end-use:

-

Seed/Table Potatoes: 4°C - 7°C (To prevent sprouting).

-

French Fry/Chip Potatoes: 8°C - 10°C.

-

Why warmer? If stored too cold (below 7°C), the starch converts to sugar ("Cold Sweetening"). When fried, the sugar caramelizes instantly, turning the fry dark brown/black and bitter.

-

-

Darkness: Essential to prevent Solanine (greening), which is toxic.

19. How do I store Root Vegetables (Carrots, Beets, Turnips)?

-

Temp: 0°C - 1°C.

-

RH: 98% - 100%.

-

Topping: Remove the green tops. The tops draw moisture out of the root even after harvest.

-

Bitterness: Keep away from apples (ethylene causes bitterness in carrots).

20. What is "Curing" and which crops need it?

Curing is a process done before cold storage to heal wounds, dry skins, and close the neck.

-

Onions/Garlic: Cured in warm, dry air until the outer skins are papery and tight.

-

Sweet Potatoes: Cured at high heat (30°C) and high humidity to heal skin and convert starches to sugars.

-

Potatoes: Cured to thicken the skin and heal cuts from the harvester.

21. How do I store Berries (Strawberries, Raspberries, Blueberries)?

-

Temp: 0°C.

-

Key: DO NOT WASH before storage. Water promotes mold instantly.

-

Shelf Life: Very short (days). They require Forced Air Cooling immediately after harvest.

-

Atmosphere: They benefit greatly from Modified Atmosphere Packaging (High CO2) to suppress Botrytis mold.

22. How do I store Citrus (Oranges, Lemons, Limes)?

-

Temp: Depends on variety.

-

Oranges: 3°C - 9°C.

-

Lemons/Grapefruit: 10°C - 13°C (More sensitive to chilling injury).

-

-

Issues: Pitting and fungal decay (Green Mold).

23. What is "Hydro-cooling"?

Drenching the produce with near-freezing water.

-

Best for: Asparagus, Cherries, Peaches, Broccoli, Carrots.

-

Pros: Very fast heat transfer; hydrates the product.

-

Cons: Spreads bacteria if water isn't chlorinated; not suitable for crops that can't get wet (strawberries, onions).

24. What is "Vacuum Cooling"?

Ideally suited for Leafy Greens and Lettuce. The produce is put in a chamber, and the pressure is dropped. Water boils off the surface of the leaves at room temperature, taking heat with it (evaporative cooling).

-

Speed: Can cool a pallet of lettuce from 25°C to 1°C in 25 minutes.

25. What is "Top Icing" or "Slush Icing"?

Injecting crushed ice or ice slurry directly into the produce box.

-

Best for: Broccoli, Sweet Corn, Green Onions.

-

Why: These crops have extremely high respiration rates and generate a lot of heat. The melting ice absorbs this heat continuously.

26. What is "Forced Air Cooling"?

The most versatile method. Fans pull cold room air through the vents in the boxes, rather than just blowing air around the pallet. It cools 75-90% faster than standard room cooling.

27. What is CA (Controlled Atmosphere) Storage?

CA is a high-tech storage method where the gas composition of the room is tightly regulated.

-

Standard Air: 21% Oxygen, 0.04% Carbon Dioxide.

-

CA for Apples: ~1-2% Oxygen, ~1-3% Carbon Dioxide.

-

Effect: By lowering oxygen, respiration is virtually halted. Apples can be stored for 9-12 months in CA without getting soft.

28. What is MAP (Modified Atmosphere Packaging)?

Similar to CA, but at the scale of a single bag or box. Special plastic films allow oxygen to enter and CO2 to exit at specific rates, creating a micro-atmosphere inside the bag that extends shelf life.

29. Can CA storage be dangerous?

Yes. For humans, entering a CA room (1% Oxygen) causes unconsciousness in seconds and death in minutes. Staff must use breathing apparatuses or vent the room fully before entering.

30. What is Botrytis cinerea?

Also known as Gray Mold. It is the most common post-harvest disease.

-

Traits: It can grow even at 0°C. It spreads by spores and contact (nesting).

-

Control: Strict temperature control, avoiding condensation, and sulfur dioxide fumigation (for Grapes).

31. What is "Soft Rot"?

Caused by bacteria (Erwinia). It turns produce into a slimy, foul-smelling mush.

-

Cause: Usually starts at a bruise or cut. It spreads rapidly in wet conditions (e.g., potatoes stored wet).

32. Why is sanitation of the cold room important?

Spores from mold survive on walls, floors, and wooden pallets.

-

Protocol: Rooms should be cleaned with quaternary ammonium or hypochlorite solutions between seasons.

-

Ozone: Using gaseous ozone during storage can help kill surface spores without wetting the product.

33. Can I use cardboard boxes in cold storage?

Yes, but they must be treated. Standard cardboard absorbs moisture from the high-humidity air and collapses. Produce boxes are typically "wax-cascaded" or made of high-grade corrugated material to withstand 95% humidity.

34. How should pallets be stacked?

-

Alignment: Ventilation holes in the boxes must align vertically and horizontally. If you block the holes, the cold air cannot reach the center of the box.

-

Spacing: Leave at least 5-10cm between pallet rows and roughly 30-50cm away from walls to ensure air circulation.

35. Why do my stored apples taste like onions?

Odor transfer. Fatty or waxy products (like the wax on apple skins or butter) absorb volatile odors from pungent crops like onions, garlic, or scallions. Always separate these groups.

36. Why is my lettuce turning pink/brown at the midrib?

This is often CO2 Injury. If you store lettuce in a sealed room or bag with poor ventilation and CO2 levels rise above 2-3%, the tissue poisons itself.

37. Why are my cucumbers getting sunken spots?

This is classic Chilling Injury. The storage temperature was likely too low (below 7°C) for too long.

38. How long can I store products?

Assuming ideal conditions:

-

Strawberries: 5-7 days.

-

Broccoli: 2-3 weeks.

-

Grapes: 2-6 months (with Sulfur pads).

-

Apples: 3 months (Air), 9-12 months (CA).

-

Potatoes: 5-9 months.

-

Onions: 6-8 months.

39. What is "Sweating" upon removal?

When cold produce is brought into a warm loading dock, moisture from the warm air condenses on the cold surface (sweating).

-

Risk: This moisture encourages rapid decay.

-

Mitigation: Gradually warm the fruit (tempering) or ensure the produce is processed/sold immediately after removal.

40. What is the role of wax coating?

Fruits like apples, citrus, and cucumbers are often waxed after washing.

-

Purpose: Washing removes the natural protective wax. Artificial wax is applied to seal in moisture (prevent shriveling) and improve cosmetic shine. It can also carry fungicides.

41. What is the danger of "Hot Spots" in a cool room?

Hot spots occur where airflow is blocked (short-cycling).

-

Consequence: The produce in the hot spot ripens faster, generating more heat (vital heat), which spreads to neighboring pallets, potentially spoiling a whole section of the inventory.

42. How do I maintain air circulation without drying the product?

You need High Volume, Low Velocity airflow.

-

Bad: A small fan blowing a hurricane at the fruit (dries it out).

-

Good: Large evaporator fans moving a massive amount of air gently across the room.

Summary Table: Quick Reference Temperature Groups

| Group | Temperature Range | Examples | Notes |

|---|---|---|---|

| Group 1: Temperate / Cold | 0°C - 2°C (32°F - 36°F) | Apples, Pears, Berries, Leafy Greens, Broccoli, Carrots, Grapes, Stone Fruit | Keep humidity high (90-95%). |

| Group 2: Cool / Moderate | 7°C - 10°C (45°F - 50°F) | Potatoes (Table), Green Beans, Peppers, Cantaloupe, Citrus | Sensitive to freezing. |

| Group 3: Warm / Chilling Sensitive | 13°C - 15°C (55°F - 60°F) | Bananas, Tomatoes, Mangoes, Pineapple, Ginger, Pumpkins | Do not refrigerate below 10°C. |

| Group 4: Low Humidity | 0°C - 2°C (But dry) | Onions, Garlic | Must be kept separate from Group 1. |