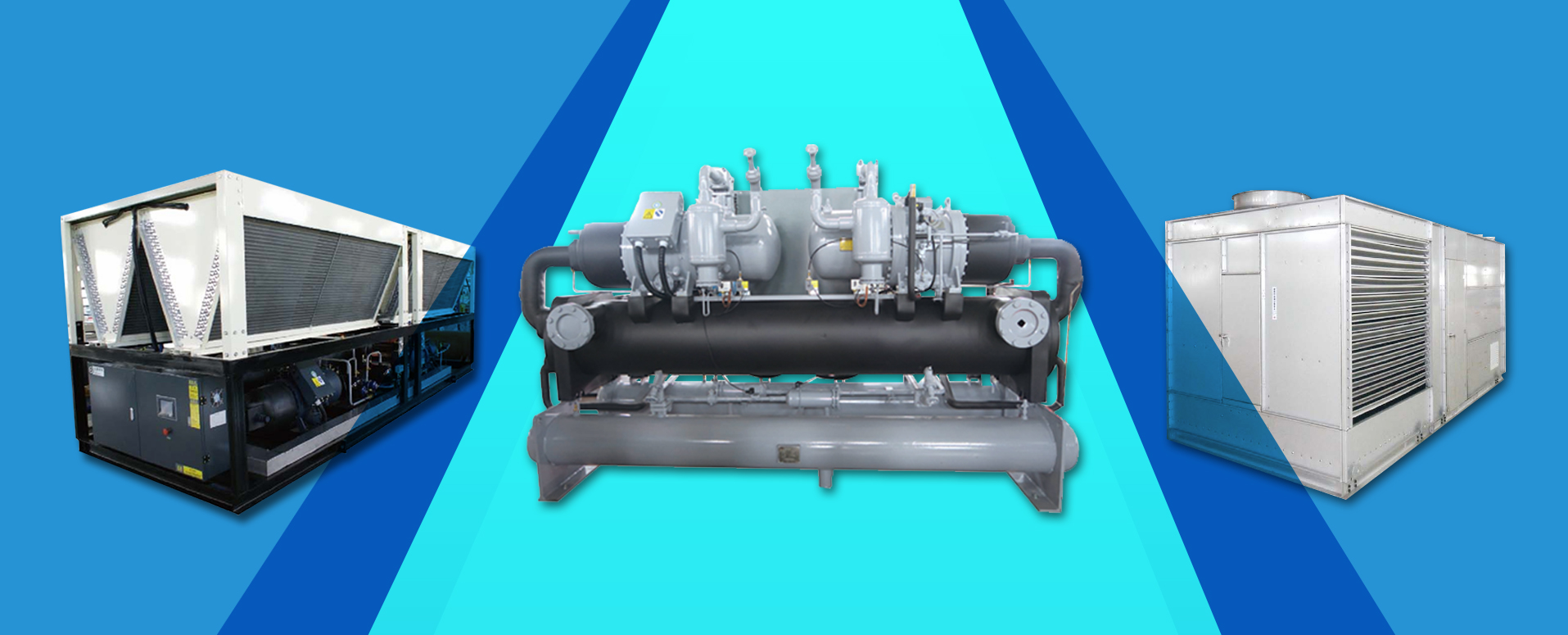

1. Product Overview

Traditional chilled water systems require on-site installation of chillers, pumps, expansion tanks, filters, and complex piping valves, entailing lengthy construction periods and substantial space requirements.

The Integrated Chiller represents a turnkey refrigeration solution. It seamlessly integrates the refrigeration host with a hydronic module—encompassing circulation pumps, buffer tanks, expansion vessels, and flow switches—within a compact enclosure or base.

This all-in-one design not only conserves valuable plant room space but also eliminates risks associated with on-site welding and component matching, making it ideal for industrial process cooling and commercial building air conditioning.

2. Core Components (All-in-One Design)

One unit, all solutions:

Chiller: Utilises high-efficiency scroll or screw compressors to deliver robust cooling capacity.

Built-in Buffer Tank: Stainless steel insulated tank prevents frequent compressor cycling, ensuring stable water temperature.

Built-in Circulation Pump: Standard high-head centrifugal pump (optional standby pump) ensures stable refrigerant circulation throughout the system.

Integrated Control: A single panel controls both refrigeration and water systems, automatically monitoring flow, pressure, and providing antifreeze protection.

3. Three Core Advantages (Key Benefits)

Plug & Play:

Factory-filled with refrigerant, pre-wired, and water-tested. Simply connect inlet/outlet pipes and power supply on-site for operation, reducing installation time by 70%.

Compact Footprint:

Requires no separate pump room or complex external piping, making it ideal for space-constrained factory workshops or rooftop platforms.

Reliability:

Factory-prefabricated piping eliminates potential leakage risks from welding debris during on-site construction; integrated flow protection and anti-freeze logic enhance system safety.

Envie Sua Mensagem

Sinta-se à vontade para entrar em contato conosco. Estamos prontos para ajudá-lo.