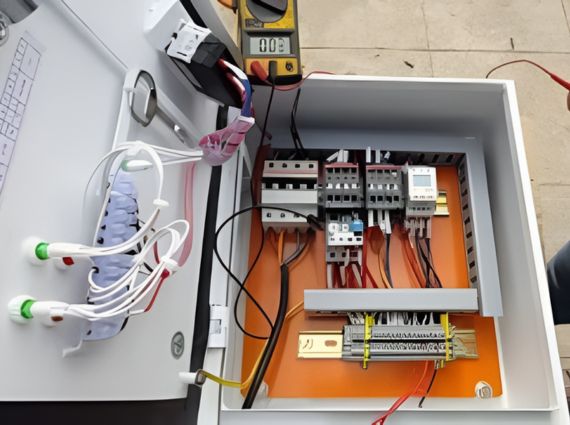

مفتاح تبديل لوحة التحكم الأوتوماتيكية لغرفة التبريد

وصف مفتاح التحويل الآلي للوحة التحكم في غرفة التبريد

يتميز مفتاح التحويل الصناعي هذا، المصمم خصيصًا لأنظمة أتمتة التبريد، بمقاومة استثنائية للغبار والماء (تصنيف IP) إلى جانب مقاومة درجات الحرارة المنخفضة، مما يضمن استقرارًا مطلقًا للاتصال الكهربائي حتى في البيئات الرطبة والباردة. يوفر مقبضه الدوار المصمم هندسيًا ردود فعل لمسية مميزة، مما يتيح للمشغلين التبديل بدقة بين أوضاع التشغيل مثل ”تلقائي/يدوي“ أو ”تبريد/تذويب“ أو ”تشغيل/إيقاف“ حتى أثناء ارتداء قفازات سميكة. يربط هذا المكون الأساسي بين المشغل ومعدات التبريد، مما يحمي بروتوكولات أمان النظام ويضمن التشغيل الفعال.

الخصائص الأساسية لمفتاح التحويل الآلي للوحة التحكم في غرفة التبريد

تحمل واسع لدرجات الحرارة

الخصائص: مصنوع من بلاستيك هندسي متخصص وشحم مقاوم لدرجات الحرارة المنخفضة.

المزايا: يعمل بشكل موثوق في نطاق درجة حرارة محيطة تتراوح من -40 درجة مئوية إلى +70 درجة مئوية. في درجات الحرارة المنخفضة للغاية لبيئات التخزين الباردة، لن يتوقف آلية المفتاح عن العمل بسبب تجمد الشحم الداخلي ولن ينكسر بسبب هشاشة البلاستيك، مما يضمن جاهزيته للتشغيل في جميع الأوقات.

تصنيف IP عالي - IP65/IP66

الميزات: تشتمل اللوحة الأمامية على تصميم حلقة مزدوجة الإغلاق، مما يلبي معايير مقاومة الغبار والماء الصناعية.

المزايا: غالبًا ما تحدث مشاكل التكثيف أو تكوّن الصقيع أو متطلبات الغسيل عند مداخل أبواب الثلاجة أو لوحات التحكم. تمنع سلامة الإغلاق العالية دخول الرطوبة إلى الأجزاء الداخلية للمفتاح، وبالتالي تجنب حدوث قصر في الدائرة الكهربائية أو تآكل، مما يضمن السلامة الكهربائية.

مادة تلامس فائقة الجودة

الخصائص: تستخدم نقاط التلامس الداخلية عادةً سبائك الفضة والنيكل (AgNi) أو مواد أكسيد الفضة والكادميوم وتتميز بوظيفة التنظيف الذاتي.

المزايا: تتميز بمقاومة تلامس منخفضة ومقاومة قوس كهربائي. عند تبديل الأحمال الحثية مثل الضواغط والمراوح أو سخانات إزالة الصقيع، فإنها تتحمل بشكل فعال طفرات التيار العابرة، مما يمنع لحام التلامس ويطيل العمر التشغيلي الكهربائي (يتجاوز عادةً 100,000 دورة).

مقبض مريح للخدمة الشاقة

الميزات: متوفر بتصميمات مقابض قياسية أو ممتدة، تتميز بنسيج مانع للانزلاق وتوفر استجابة لمسية واضحة وثابتة أثناء الدوران.

المزايا: مصمم خصيصًا لمشغلي غرف التبريد الذين يرتدون قفازات سميكة وعازلة للحرارة بشكل متكرر. يسمح المفتاح المقوى بتغيير التروس بسهولة ودقة دون الحاجة إلى خلع القفازات، مما يمنع التشغيل العرضي.

· ورشات تجهيز الأغذية

· مخازن التبريد وغرف التجميد

· مراكز لوجستيات سلسلة التبريد ومستودعات التوزيع

· مصانع الأدوية وغرف التنظيف

· المختبرات البيولوجية ومستودعات العينات

· غرف حفظ الزهور

· التخزين بدرجات حرارة منخفضة لـ

|

نوع المنتج |

لوحة التحكم في غرفة التبريد |

| مصدر الطاقة | 380VAC,50/60Hz |

| نطاق قياس درجة الحرارة | -50℃ to 50℃ |

| نطاق التحكم في درجة الحرارة | -40℃℃ to 119℃ |

| دقة قياس درجة الحرارة | +1℃ |

| قرار | 0.1℃ |

| سعة التلامس (الضاغط) | 14A, 21A,28A,35A,56A |

| سعة التلامس (إذابة الجليد) | 14A,21A,28A,35A,56A |

| سعة التلامس (مروحة) | 7A |

| نوع المستشعر | NTC (10KQ/25°C, B-3435K) |

| التواصل | شبكة RS-485، واي فاي (2.4 جيجاهرتز) |

| وقت حماية تأخير الضاغط 1-110 دقيقة (قابلة للتعديل) |

مفاتيح الاختيار لألواح التخزين البارد: أسئلة وأجوبة شاملة

القسم 1: الوظائف ومنطق التشغيل

س 1: ما هو الدور المحدد لمفتاح الاختيار في لوحة التحكم الأوتوماتيكية للتخزين البارد؟

يعمل مفتاح الاختيار كجسر واجهة الإنسان والآلة (HMI) الحيوي بين المشغل ونظام أتمتة التخزين البارد (عادةً ما يكون PLC أو وحدة تحكم رقمية). وتتمثل وظيفته الأساسية في تحديد وضع تشغيل معدات التبريد. على عكس الزر البسيط الذي يوفر إشارة مؤقتة، يحافظ مفتاح الاختيار على حالة التلامس، ويوجه النظام للبقاء في حالة منطقية محددة — مثل ”تلقائي“ أو ’يدوي‘ أو ”إيقاف“ أو أوضاع تذويب محددة — حتى يتم تغييره فعليًا بواسطة المشغل. ويضمن أن يكون سلوك النظام متعمدًا ويمنع التغييرات العرضية في الوضع.

السؤال 2: لماذا يعتبر تكوين ”الإيقاف التلقائي-اليدوي“ (H-O-A) شائعًا جدًا في لوحات التخزين البارد؟

يعد التكوين ”Hand-Off-Auto“ (HOA) أو ”Manual-Off-Auto“ هو المعيار الصناعي لبروتوكولات السلامة والصيانة:

تلقائي: يتم التحكم في النظام بواسطة أجهزة استشعار (ثرموستات) و PLC. يقوم بتشغيل الضواغط والمراوح بناءً على متطلبات درجة الحرارة. هذه هي حالة التشغيل العادية.

إيقاف التشغيل: الدائرة معطلة فعليًا. لن تعمل المعدات بغض النظر عن ارتفاع درجة الحرارة. يستخدم هذا الإعداد لإجراء فحوصات بسيطة أو إيقاف تشغيل منطقة معينة.

يدوي (يدوي): يتجاوز هذا الإعداد أجهزة الاستشعار ومنطق PLC، مما يجبر الموصل على الإغلاق وتشغيل المعدات بشكل مستمر. هذا أمر بالغ الأهمية للتبريد في حالات الطوارئ في حالة فشل وحدة التحكم، أو لاختبار أداء الضاغط أثناء الصيانة.

السؤال 3: هل يمكن استخدام هذه المفاتيح لتشغيل المضخة وإيقافها مباشرة؟

بشكل عام، لا، لا ينبغي استخدامها لتبديل خط الطاقة الرئيسي لمضخة كبيرة بشكل مباشر. عادةً ما يتم تصنيف هذه المفاتيح لتطبيقات ”دائرة التحكم“ (الخدمة التجريبية). فهي تقوم بتبديل الإشارة منخفضة التيار (على سبيل المثال، جهد التحكم 24 فولت تيار مستمر أو 220 فولت تيار متردد) التي تزود الملف الكهرومغناطيسي للموصل بالطاقة. ثم يتعامل الملامس مع الحمل عالي التيار للضاغط. في حين توجد بعض مفاتيح الكامات الثقيلة التي يمكنها التعامل مع أحمال المحرك (فئة AC-3)، إلا أن مفتاح الاختيار في لوحات التخزين البارد الآلية الحديثة هو جهاز تحكم حصري تقريبًا لحماية المشغل وآلية التبديل.

السؤال 4: ما الفرق بين مفتاح الاختيار ”المحافظ عليه“ و”المرتجع بالزنبرك“ في هذا السياق؟

ثابت (قفل): عندما تدير المفتاح إلى وضع معين (مثل ”إذابة الجليد“)، فإنه يظل في هذا الوضع حتى تعيده إلى الوضع السابق. يستخدم هذا الوضع لضبط أوضاع التشغيل (تلقائي/يدوي) التي يجب أن تظل نشطة لساعات أو أيام.

الرجوع الزنبركي (لحظي): عندما تترك المفتاح، فإنه يعود إلى الوضع المركزي أو الوضع الأصلي. يستخدم هذا غالبًا لوظائف ”إعادة الضبط“ أو لتشغيل دورة ”ضخ لأسفل“ يدوية حيث يجب أن يكون المشغل حاضرًا ممسكًا بالمفتاح لتنفيذ الإجراء، مما يضمن السلامة.

السؤال 5: كيف يتعامل المفتاح مع منطق ”إذابة الجليد“ المحدد؟

في العديد من اللوحات، يتيح مفتاح اختيار مخصص للمشغلين فرض ”إذابة يدوية“. عند التبديل إلى هذا الوضع، يرسل المفتاح إشارة إلى وحدة التحكم لتجاوز المؤقت، مما يؤدي إلى إغلاق الصمام اللولبي على الفور وتشغيل عناصر السخان الكهربائي أو عكس الصمام (لإذابة الجليد بالغاز الساخن). وهذا ضروري عندما يلاحظ المشغلون تراكمًا مفرطًا للجليد على ملفات المبخر قد تكون أجهزة الاستشعار التلقائية قد أغفلتها أو إذا ترك الباب مفتوحًا لفترة طويلة.

القسم 2: الاستدامة البيئية وعلوم المواد

س 6: لماذا لا يمكنني استخدام مفتاح كهربائي منزلي عادي للوحة التخزين البارد؟

المفاتيح القياسية غير مصممة لتحمل الإجهاد الحراري لبيئات التخزين الباردة. نقاط الفشل الرئيسية للمفاتيح القياسية في البيئات الباردة هي:

تجمد مواد التشحيم: تتصلب الشحوم الداخلية في المفاتيح القياسية عند درجات الحرارة المنخفضة، مما يتسبب في توقف الآلية أو جعلها صلبة للغاية.

تقصف البلاستيك: يخضع البلاستيك القياسي لـ ”انتقال زجاجي“ ويصبح هشًا، ويتحطم عند تدويره بقوة.

التكثف: تفتقر هذه المفاتيح إلى الحشيات المانعة للتسرب اللازمة لمنع دخول الرطوبة، مما يؤدي إلى حدوث ماس كهربائي.

تستخدم مفاتيح التخزين البارد مواد تشحيم اصطناعية منخفضة الحرارة وبلاستيك هندسي مقوى (مثل البولي كربونات أو البولي أميد عالي الجودة) لتحمل هذه الظروف.

س 7: ما هو تصنيف IP (حماية الدخول) الموصى به لهذه المفاتيح؟

بالنسبة للوحات التحكم في غرف التبريد، فإن التصنيف الأدنى الموصى به هو IP65.

IP65: مقاومة للغبار ومحمية ضد نفاثات الماء ذات الضغط المنخفض. وهذا ضروري لأن لوحات التحكم غالبًا ما تكون موجودة في الممرات أو أرصفة التحميل التي تخضع لإجراءات الغسل.

بالنسبة للوحات الموجودة داخل غرفة التبريد نفسها (وهو أمر نادر الحدوث ولكنه يحدث)، يفضل استخدام IP66 أو IP67 للتعامل مع ضغط الماء العالي واحتمال تكوّن الجليد على سطح اللوحة.

س 8: كيف يأخذ تصميم المفتاح في الاعتبار ارتداء المشغلين لقفازات حرارية سميكة؟

تعتبر بيئة العمل مهمة في سلاسل التبريد. يفضل استخدام مشغل من نوع ”مقبض طويل“ أو ’رافعة‘ على مقبض قصير ”يمسك بالإبهام“. توفر الرافعة الأطول قوة رفع أفضل ومؤشرًا مرئيًا لموضع المفتاح. بالإضافة إلى ذلك، يجب زيادة المسافة بين المفاتيح على اللوحة (عادةً 50 مم أو أكثر من المركز إلى المركز) لمنع اليد المقفازة من الاصطدام بالزر المجاور عن طريق الخطأ أثناء تشغيل المفتاح.

س 9: هل سيؤثر التكثف على التلامس الكهربائي داخل المفتاح؟

يعد التكثف تهديدًا كبيرًا. حتى إذا كان المفتاح مغلقًا بإحكام، فإن تقلبات درجة الحرارة يمكن أن تسبب ”تنفسًا“ داخليًا حيث يدخل الهواء الرطب ويتكثف. لمكافحة ذلك، تستخدم مفاتيح التخزين البارد عالية الجودة نقاط تلامس من الفضة والنيكل (AgNi) أو مطلية بالذهب. هذه المواد مقاومة للأكسدة والتآكل. علاوة على ذلك، غالبًا ما تتضمن الحركة الميكانيكية للمفتاح حركة احتكاك ”مسح“ أو ”تنظيف ذاتي“ تقشط أي تآكل دقيق في كل مرة يتم فيها تشغيل المفتاح، مما يضمن اتصالًا كهربائيًا جيدًا.

السؤال 10: ما هو نطاق درجة حرارة التشغيل لهذه المفاتيح؟

عادةً ما يتميز مفتاح الاختيار الصناعي عالي الجودة المخصص لتطبيقات التبريد بنطاق درجة حرارة تشغيلية تتراوح من -25 درجة مئوية إلى +70 درجة مئوية (-13 درجة فهرنهايت إلى +158 درجة فهرنهايت). يمكن أن تعمل الإصدارات ”القطبية“ المتخصصة حتى -40 درجة مئوية. من الضروري التحقق من أن المفتاح مصمم لدرجة حرارة البيئة المحيطة التي يوجد بها اللوحة — غالبًا ما تكون اللوحة خارج الفريزر في منطقة أكثر دفئًا قليلاً، ولكن يجب أن تتحمل التيارات الهوائية الباردة والتوصيل الحراري من الجدار.

القسم 3: التركيب والسلامة والصيانة

س 11: ما هو قطر التثبيت القياسي لهذه المفاتيح؟

المعيار الصناعي العالمي لتركيب مفاتيح التحكم الصناعية هو 22 مم (بالتحديد Ø22.3 مم). تسمح هذه التوحيد القياسي بسهولة الاستبدال. في حالة تعطل أحد المفاتيح، يمكنك استبداله بآخر احتياطي من مختلف الشركات المصنعة (مثل Schneider أو ABB أو Siemens أو العلامات التجارية المتخصصة في أنظمة التدفئة والتهوية وتكييف الهواء) دون الحاجة إلى حفر ثقوب جديدة في خزانة التحكم المصنوعة من الفولاذ المقاوم للصدأ.

السؤال 12: كيف يتم تكوين كتل الاتصال؟ هل يمكنني إضافة المزيد من الوظائف؟

هذه المفاتيح قابلة للتعديل. يتم توصيل رأس المشغل (المقبض) بمزلاج التثبيت، الذي يحمل بدوره ”كتل التلامس“. يمكنك تكديس هذه الكتل.

NO (مفتوح عادة): يستخدم لبدء الدائرة (على سبيل المثال، تشغيل الوضع ”تلقائي“).

NC (مغلق عادةً): يُستخدم لقطع الدائرة (على سبيل المثال، وضع ”إيقاف“ أو ”إيقاف التشغيل“).

بالنسبة للوحة التخزين البارد، يمكنك تكديس عدة كتل بحيث يؤدي التحويل إلى ”يدوي“ إلى تشغيل الضاغط وتفعيل ضوء تحذير في نفس الوقت.

س 13: هل هناك شهادات سلامة محددة مطلوبة؟

نعم. بالإضافة إلى علامات السلامة الكهربائية القياسية (مثل CE في أوروبا أو UL/CSA في أمريكا الشمالية)، يجب أن تكون المواد متوافقة مع RoHS (خالية من المواد الخطرة). والأهم من ذلك، يجب أن يكون الغلاف البلاستيكي مقاومًا للهب (تصنيف V0). في حالة حدوث قصر كهربائي داخل اللوحة، يجب أن تنطفئ مادة المفتاح ذاتيًا وألا تساهم في انتشار الحريق، وهو معيار أمان بالغ الأهمية في مستودعات التخزين الباردة المعزولة حيث ينتشر الحريق بسرعة.

س 14: كيف يمكنني تحديد ما إذا كان مفتاح الاختيار معطل؟

تشمل العلامات الشائعة للفشل ما يلي:

إحساس ”باللين“: اختفاء ”الطقطقة“ (القفل) المميزة، مما يشير إلى تآكل النوابض أو الكامات الداخلية أو تدهور حالة الشحم.

التشغيل المتقطع: يجب تحريك المفتاح في وضع ”تلقائي“ لتشغيل الضاغط. يشير ذلك إلى أكسدة التلامس أو وجود أطراف توصيل مفكوكة.

الحرارة: إذا كان الجزء الخلفي من المفتاح ساخنًا، فهذا يعني أن نقاط التلامس تقاوم تدفق التيار، مما يشكل خطرًا للحريق.

س 15: هل يمكنني غسل لوحة التحكم بخرطوم ضغط عالي؟

حتى إذا كان المفتاح مصنفًا بدرجة IP65/IP66، لا يُنصح باستخدام رشاشات الضغط العالي (الغسيل بالضغط) من مسافة قريبة. يمكن أن يؤدي الضغط العالي إلى تسرب المياه حتى من أفضل الأختام بمرور الوقت، خاصةً إذا كانت الحشيات المطاطية قد تقادمت وتصلبت في البيئة الباردة. يوصى بمسح سطح اللوحة بقطعة قماش مبللة ومنظف معتدل، أو استخدام رشاش منخفض الضغط، مع التأكد من عدم المساس بسلامة الختم.

القسم 4: المواصفات المتقدمة واستكشاف الأخطاء وإصلاحها

س 16: ما هو تصنيف ”التيار الحراري“ (Ith) ولماذا هو مهم؟

يشير تصنيف Ith (التيار الحراري التقليدي في الهواء الحر)، الذي يبلغ عادةً 10 أمبير لهذه المفاتيح، إلى الحد الأقصى للتيار الذي يمكن للمفتاح حمله بشكل مستمر دون ارتفاع درجة الحرارة. على الرغم من أن إشارة دائرة التحكم قد تكون 0.5 أمبير فقط، فإن تصنيف 10 أمبير يوفر هامش أمان قويًا ضد التيارات المفاجئة ويضمن أن تكون نقاط التلامس قوية بما يكفي لتدوم لسنوات من التشغيل.

س 17: كيف تؤثر اهتزازات الضواغط على المفتاح؟

يتم في بعض الأحيان تركيب لوحات التحكم في التخزين البارد مباشرة على حامل الضاغط أو وحدة التكثيف. وهذا يعرض المكونات لاهتزازات مستمرة. تتميز المفاتيح عالية الجودة بمسامير طرفية مقاومة للاهتزاز (غالبًا مع غسالات مثبتة) وآلية قفل إيجابية لكتل التلامس. إذا تم استخدام مفتاح رخيص، فقد يتسبب الاهتزاز في انفصال كتل التلامس وسقوطها، مما يؤدي إلى إيقاف تشغيل النظام فجأة.

س 18: هل من الممكن قفل المفتاح في وضع ”إيقاف التشغيل“؟

نعم، هذه ميزة أمان مهمة تُعرف باسم LOTO (Lock-Out, Tag-Out). تتوفر العديد من مفاتيح الاختيار المزودة بـ”مقبض قابل للقفل“. وهذا يسمح لفني الصيانة بتحويل النظام إلى وضع ”إيقاف التشغيل“، وإدخال قفل عبر مقبض المفتاح، والدخول إلى غرفة التبريد لخدمة مراوح المبخر دون خوف من أن يقوم شخص آخر بتحويل النظام عن طريق الخطأ إلى وضع ”تلقائي“.

س 19: ما هو الجهد الكهربائي المحدد لهذه المفاتيح عادةً؟

عادةً ما يكون جهد العزل (Ui) مصنّفًا لـ 690 فولت، ولكن في الواقع، فإنه يتحكم في الدوائر التي تعمل بجهد 24 فولت تيار متردد/تيار مستمر، أو 110 فولت تيار متردد، أو 230 فولت تيار متردد. من الضروري التأكد من أن مؤشر LED (إذا كان المفتاح مزودًا بمقبض مضيء) يتوافق مع جهد التحكم. سيؤدي استخدام وحدة LED بجهد 24 فولت في دائرة بجهد 230 فولت إلى تلف المصباح على الفور.

س 20: هل يمكنني استخدام مفتاح اختيار مضيء للتخزين البارد؟

نعم، مفاتيح الاختيار المضيئة تحظى بشعبية كبيرة. فهي تجمع بين المفتاح ومصباح الإرشاد في جهاز واحد.

ضوء LED أخضر مضاء: النظام في الوضع التلقائي وقيد التشغيل.

ضوء LED أحمر مضاء: النظام في حالة إنذار أو توقف.

الميزة هي توفير مساحة اللوحة. ومع ذلك، في البيئات شديدة البرودة، تُفضل تقنية LED على المصابيح المتوهجة، حيث لا تتأثر مصابيح LED بالاهتزازات وتعمل بشكل جيد في درجات الحرارة الباردة (مما يطيل من عمر مصابيح LED)، في حين أن خيوط المصابيح المتوهجة تصبح هشة.