Applications Across Industries

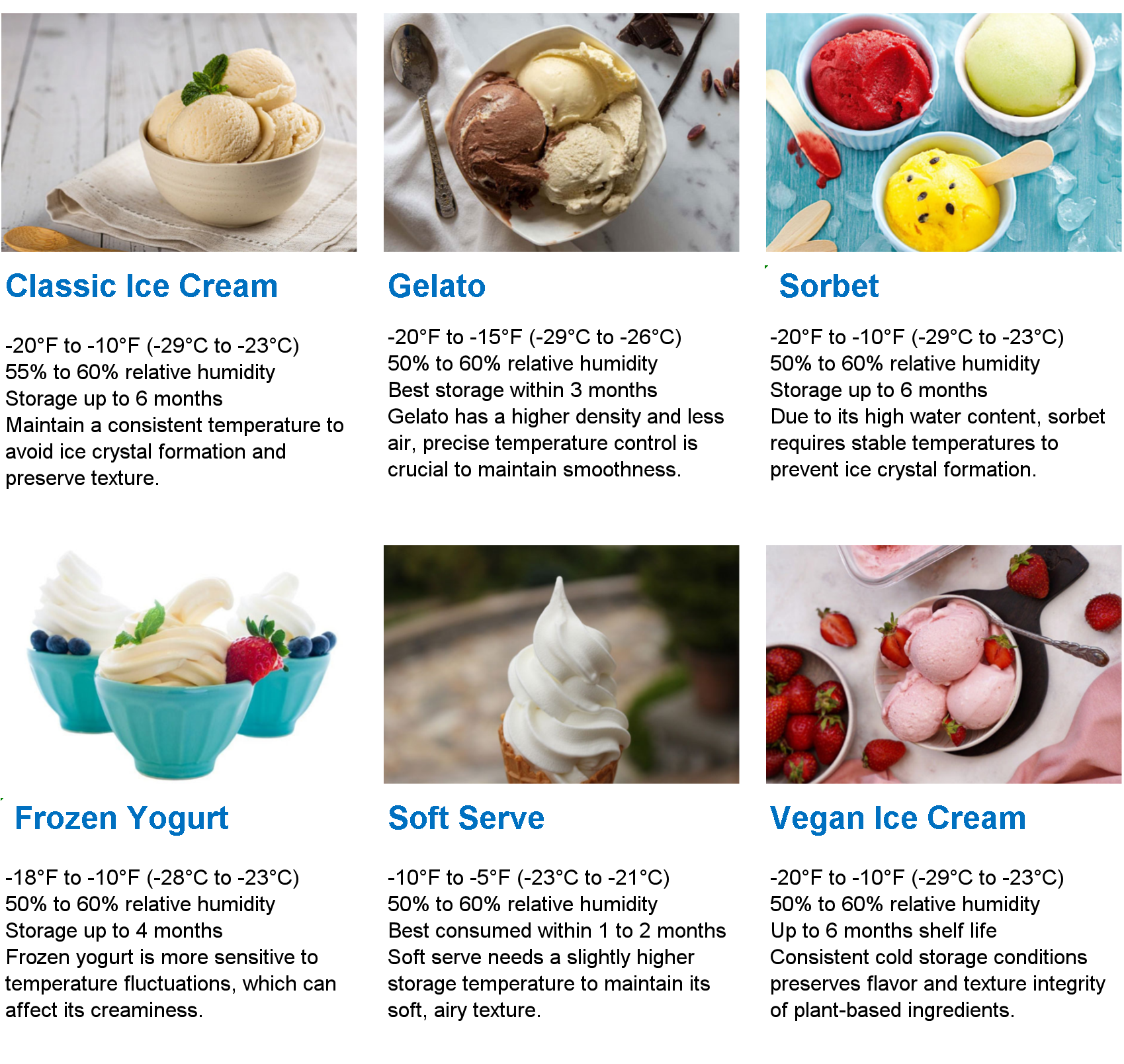

Ice Cream Manufacturers

Ice Cream Manufacturers

Ice Cream Manufacturers

Retail Chains & Supermarkets

Retail Chains & Supermarkets

Retail Chains & Supermarkets

Ice Cream Parlors & Cafes

Ice Cream Parlors & Cafes

Ice Cream Parlors & Cafes

Compact cold rooms support daily operations by storing various flavors and toppings at optimal temperatures, ensuring freshness and quick access for serving customers.

Distributors & Wholesalers

Distributors & Wholesalers

Comprehensive FAQ: Ice Cream Cold Storage & Cold Chain Management

Q1: What makes ice cream storage different from standard frozen food storage?

A: The primary difference lies in the sensitivity of the product structure and the required temperature.

While frozen meat or vegetables are generally safe at -18°C (0°F), ice cream requires significantly lower temperatures. Ice cream is a complex emulsion of fat, sugar, air bubbles, and ice crystals.

-

Texture Sensitivity: If the temperature fluctuates or isn't cold enough, the microscopic ice crystals within the ice cream will melt and re-freeze into larger, jagged crystals. This ruins the creamy texture, making it "sandy" or "crunchy" (a phenomenon known as Heat Shock).

-

Air Content (Overrun): Ice cream contains air. Temperature changes can cause the air to escape, leading to "shrinkage" where the product volume decreases inside the packaging.

Q2: What is the ideal temperature for an ice cream cold room?

A: There are two distinct stages, each requiring different temperatures:

-

Hardening Phase: Immediately after production, ice cream is soft (semisolid). It must be rapidly frozen to lock in the structure. This is done in a Hardening Tunnel or Blast Freezer at -30°C to -40°C (-22°F to -40°F).

-

Long-term Storage (Holding): Once hardened, the ice cream is moved to a holding freezer. The industry standard for long-term storage is -25°C (-13°F).

-

Note: Standard freezers at -18°C are generally acceptable for short-term display in supermarkets, but for warehousing and logistics, -25°C is critical to extend shelf life and maintain premium quality.

-

Q3: What is "Heat Shock," and why is it the enemy of ice cream?

A: Heat shock is the cumulative damage caused by temperature fluctuations.

Even if the ice cream never fully melts (e.g., rising from -25°C to -15°C and back down), damage occurs. When the temperature rises, the smallest ice crystals melt first. When the temperature drops again, that water doesn't form new small crystals; instead, it attaches to existing larger crystals, making them grow.

Result: The ice cream loses its smoothness. A good cold room design must prioritize temperature stability to prevent this.

Q4: What thickness of insulation panels (PU Panels) is recommended?

A: Because of the large temperature difference between the outside air (e.g., +30°C) and the interior (-25°C), high-performance insulation is non-negotiable.

-

Material: Polyurethane (PU) or Polyisocyanurate (PIR) sandwich panels are standard due to their excellent thermal conductivity and fire resistance.

-

Thickness:

-

For standard freezers (-18°C), 100mm or 120mm is common.

-

For Ice Cream Freezers (-25°C to -30°C), the recommended thickness is 150mm to 200mm.

Using thinner panels will result in higher electricity bills, compressor overwork, and potential condensation (sweating) on the exterior walls.

-

Q5: Do I need special flooring for an ice cream cold storage?

A: Yes, absolutely. You cannot simply build a -25°C freezer on a standard concrete slab.

-

Floor Insulation: You must have XPS (Extruded Polystyrene) insulation boards beneath the concrete floor to prevent cold loss.

-

Anti-Frost Heave Protection: The cold from the room will eventually penetrate the insulation and freeze the soil deep underground. When soil moisture freezes, it expands, cracking the concrete floor and even lifting the building foundation. This is called Frost Heave.

-

Solution: Install an underfloor heating system (electric heating cables or glycol ventilation pipes) beneath the floor insulation to keep the sub-soil above 0°C.

-

Q6: Why is an "Ante-Room" (Air Lock) critical for ice cream storage?

A: An Ante-Room is a transition zone (kept at around +5°C to +10°C) between the ambient outside air and the deep freezer.

-

Moisture Control: At -25°C, infiltrating air creates immediate fog, snow, and ice buildup on the ceiling and evaporator. An ante-room acts as a dehumidifying buffer, capturing moisture before it enters the freezer.

-

Energy Saving: It prevents the massive heat load that occurs when a door is opened directly to the outside.

-

Door Freezing: Without an ante-room, the temperature difference is so extreme that freezer doors may freeze shut or gaskets may become brittle.

Q7: Which refrigerant is best for industrial ice cream cold rooms?

A: The choice depends on the size of the facility and local environmental regulations.

-

Ammonia (R717): The "Gold Standard" for large industrial ice cream plants. It is extremely efficient, has zero Global Warming Potential (GWP), and zero Ozone Depletion Potential (ODP). However, it is toxic and requires specialized safety protocols.

-

CO2 (R744): Increasingly popular for mid-to-large facilities. It is environmentally friendly and very efficient at low temperatures.

-

Freons (HFCs): For smaller walk-in freezers. R404A is the traditional choice but is being phased out due to high GWP. Newer alternatives include R448A or R449A.

Q8: How should the Defrost Cycle be managed?

A: Ice cream freezers accumulate frost on the evaporator coils faster than other cold rooms because the temperature difference removes moisture from the air rapidly.

-

Electric Defrost: Common in smaller units. Uses heater rods.

-

Hot Gas Defrost: Used in larger industrial systems. It reverses the cycle to send hot gas through the coils. It is faster and more energy-efficient than electric defrost.

-

Critical Protocol: During defrost, the temperature in the room rises slightly. The system must be designed to defrost quickly to ensure the air temperature doesn't impact the product temperature.

Q9: What is the importance of "Pull-Down Time"?

A: Pull-down time refers to how fast the refrigeration unit can bring the temperature back to -25°C after doors have been opened for loading/unloading.

For ice cream, a rapid recovery is essential. If the unit is underpowered, the room may sit at -15°C for hours after loading, causing heat shock. The refrigeration capacity calculation must account for heavy forklift traffic and product load.

Q10: How should ice cream pallets be stacked for optimal airflow?

A: Proper airflow is crucial to ensure every carton stays at -25°C.

-

The "Chimney" Effect: Do not stack pallets tightly against each other. Leave a gap (5-10cm) between pallets.

-

Wall Clearance: Never stack product directly against the wall. Leave at least 30cm clearance. This prevents heat transfer from the walls and allows cold air to circulate the perimeter.

-

Ceiling Clearance: Do not block the airflow from the evaporator fans. If the air jet is blocked, the back of the room will become a "hot spot."

Q11: Can I store other products with ice cream?

A: Generally, no.

-

Temperature Mismatch: Most frozen foods (meat, fries, peas) only need -18°C. Keeping them at -25°C is a waste of energy. Conversely, keeping ice cream at -18°C ruins the quality.

-

Odor Transfer: Ice cream is high in fat, which absorbs odors readily. Storing fish or heavily spiced items in the same room can taint the flavor of the ice cream (even through packaging).

Q12: What type of lighting should be used?

A: You must use LED lighting specifically rated for low temperatures.

-

Instant On: Older lighting types (fluorescent/metal halide) take time to warm up and struggle in the cold.

-

Heat Output: LEDs emit very little heat, reducing the load on the refrigeration system.

-

Durability: Standard electronics fail at -25°C. The drivers and casings must be IP65 waterproof (to withstand washdowns) and freezer-rated.

Q13: I see ice formation on the ceiling and near the door. What is wrong?

A: Ice formation indicates air infiltration. Warm, humid air is leaking into the room.

-

Check Door Seals: The gasket is likely torn or not sealing tight.

-

Check Door Heaters: If the door frame heater is broken, ice will form on the frame, preventing the door from closing fully.

-

Strip Curtains: Ensure PVC strip curtains or an air curtain is installed and functional to minimize air exchange when the door is open.

-

Panel Joints: In older cold rooms, the silicone sealant between panels may have cracked, allowing outside air in.

Q14: Why is my ice cream shrinking inside the tub?

A: This is a defect caused by altitude changes or severe temperature fluctuations.

If the external pressure drops (e.g., transporting over mountains) or the temperature warms up significantly, the air bubbles inside the ice cream expand and escape. When cooled again, the structure collapses, causing the ice cream to pull away from the container walls. Maintaining a constant -25°C throughout the supply chain prevents this.

Q15: What safety precautions are needed for workers in -25°C?

A: Working in an ice cream freezer is hazardous due to the extreme cold.

-

PPE: Workers must wear thermal suits, insulated gloves, and hats rated for -30°C.

-

Time Limits: Limit continuous working time (e.g., 45 mins inside, 15 mins warm-up break).

-

Man-Trap Alarm: Every walk-in freezer must have an internal safety release mechanism on the door and a "Trapped Person Alarm" button that functions even if the power is out.

-

Floor Ice: Ice cream floors can become slippery if humidity enters. Anti-slip footwear is mandatory.

Q16: How can I reduce the energy cost of my ice cream cold room?

A: Ice cream storage is one of the most energy-intensive types of warehousing.

-

High-Speed Doors: Use automated rapid-roll doors that open and close in seconds.

-

Evaporator Cleaning: Keep coils clean. Dust and debris insulate the coils, making the fridge work harder.

-

Smart Defrost: Switch from "timer-based" defrost (e.g., every 6 hours) to "demand-based" defrost (sensors detect when ice is actually present).

-

Load Management: Try to run heavy freezing cycles at night when electricity tariffs are often lower (Off-Peak cooling).

Q17: What is the maintenance schedule for the "Underfloor Heater"?

A: This is often overlooked until the floor cracks.

-

Monthly: Check the amperage draw of the heating cables. If the current is zero, the heater has failed.

-

Observation: Look for "heaving" or unevenness in the floor, or cracks appearing near the center of the room. If this happens, the heater must be repaired immediately to prevent structural failure of the building.

Q18: What is "Glazing" in the context of ice cream storage?

A: While not a storage technique, glazing applies to ice cream bars or novelties. It involves dipping the product in water or a coating to form a protective shell. In storage, if the temperature fluctuates, this glaze can crack. Therefore, the humidity inside the cold room should also be controlled (kept low) to prevent frost from settling on the packaging, which damages cardboard boxes and makes labels unreadable.

Q19: What should I do if the power goes out?

-

DO NOT OPEN THE DOOR: This is the golden rule. A well-insulated ice cream freezer can hold temperature for several hours if sealed.

-

Start Backup Generator: Essential for ice cream facilities.

-

Dry Ice (CO2): If the outage is prolonged (days), you can place blocks of dry ice on the floor (never on top of the product directly without barriers). As dry ice sublimates, it keeps the room cold. Ensure proper ventilation before re-entering, as CO2 displaces oxygen.

-

Liquid Nitrogen: Some advanced systems have injection ports for emergency liquid nitrogen cooling.

Q20: How do I test if the cold room is performing correctly?

A: You need to perform Temperature Mapping.

Place data loggers in the corners, the center, near the door, and near the evaporator. Run the room for 24-48 hours.

-

Success: All sensors read between -24°C and -26°C.

-

Failure: Some sensors read -18°C (Hot Spots) while others read -30°C. This indicates poor airflow circulation, requiring baffle adjustments or restacking of the product.

Date de publication : Sep-25-2020