-

LAC02-6.4 Unidad interior para cámara frigorífica

-

LAC35-10.0 Cold Room indoor Unit

-

LAC28-10.0 Cold Room indoor Unit

-

LAC21-10.0 Cold Room indoor Unit

-

LAC17-10.0 Cold Room indoor Unit

-

LAC14-10.0 Cold Room indoor Unit

-

LAC11-10.0 Cold Room indoor Unit

-

LAC07-10.0 Cold Room indoor Unit

-

LAC04-10.0 Cold Room indoor Unit

-

LAC14-6.4 Cold Room indoor Unit

-

LAC09-6.4 Cold Room indoor Unit

-

LAC07-6.4 Cold Room indoor Unit

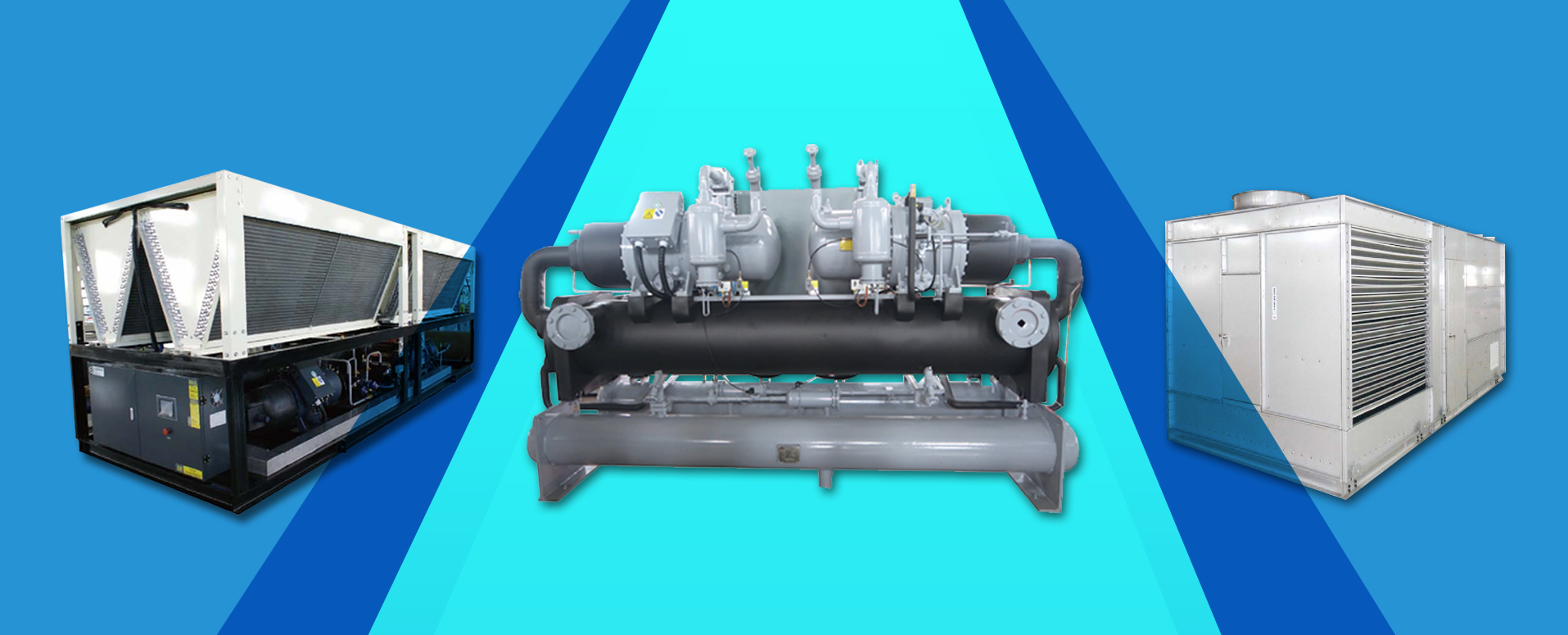

1. Product Overview

This series of air coolers (also known as ceiling-mounted evaporators) are forced convection heat exchange units specifically designed for cold storage interiors. They absorb heat from within the storage facility via high-efficiency internal coils, utilising axial fans to uniformly distribute cool air throughout every corner of the chamber for rapid temperature reduction.

Featuring a compact design for ceiling installation, these units maximise floor storage space. We offer three standardised series – Fresh-keeping, Freezing, and Quick-freezing – tailored to different storage temperatures, perfectly compatible with all types of Freon refrigeration units.

2. Series & Classification

Within the cold storage industry, air coolers are typically categorised into three main series based on fin spacing to accommodate varying frosting conditions:

2.1 DL Series (High-temperature type)

Fin Spacing: 4.5 mm

Operating Temperature: Around 0°C (primarily for temperatures above -5°C)

Typical Applications: Vegetable and fruit preservation cold stores, egg storage, floral storage, pharmaceutical cool storage.

Features: Dense fins provide extensive heat exchange surface area, effectively maintaining humidity within the storage area and reducing moisture loss in produce.

2.2 DD Series (Medium-Temperature Type) - Most Commonly Used

Fin Spacing: 6.0 mm

Operating Temperature: Approximately -18°C (primarily for -15°C to -25°C)

Typical Applications: Meat refrigeration, seafood freezing, ice cream storage.

Characteristics: Moderate fin spacing design ensures heat transfer efficiency while preventing excessive frost buildup and blockage during freezing operations.

2.3 DJ Series (Low-Temperature Type)

Fin spacing: 9.0 mm

Operating temperature: Below -25°C (primarily for -35°C blast-freezing chambers)

Typical Applications: Food rapid-freezing tunnels, fresh meat rapid-freezing chambers.

Features: Extra-wide fin spacing design prevents airflow blockage from heavy frost accumulation during rapid freezing, ensuring prolonged operation without frequent defrosting.

3.1 High-Efficiency Heat Exchange Core

Copper Tubing: High-purity seamless copper tubing with internally grooved surfaces to maximise refrigerant contact area.

Fins: Hydrophilic aluminium fins mechanically expanded to form a tight bond with copper tubing, minimising thermal resistance.

Optimised Flow Path: Professional refrigerant distribution design ensures uniform refrigerant allocation across each circuit for peak evaporation efficiency.

3.2 Robust Air Distribution System

Long-Range Coverage: Equipped with high-efficiency axial fans and specialised air deflectors, achieving airflow distances of 10-30 metres (depending on model) to eliminate temperature dead zones within storage areas.

Low-Temperature Motor: Utilises specialised low-temperature motors with insulation class F or higher, fitted with moisture-resistant bearings for stable operation down to -40°C.

3.3 Premium Enclosure and Defrosting

Enclosure Material: Standard powder-coated galvanised steel (corrosion-resistant and durable). Optional 304 stainless steel for food processing areas (compliant with HACCP hygiene standards).

Rapid Defrosting: High-quality stainless steel electric heating elements are directly inserted into the coil interior, ensuring swift and thorough defrosting. The drip tray features double-layer insulation to prevent secondary freezing of defrost water.

Envíe su Mensaje

Siéntase libre de contactarnos. Estamos listos para ayudarle.