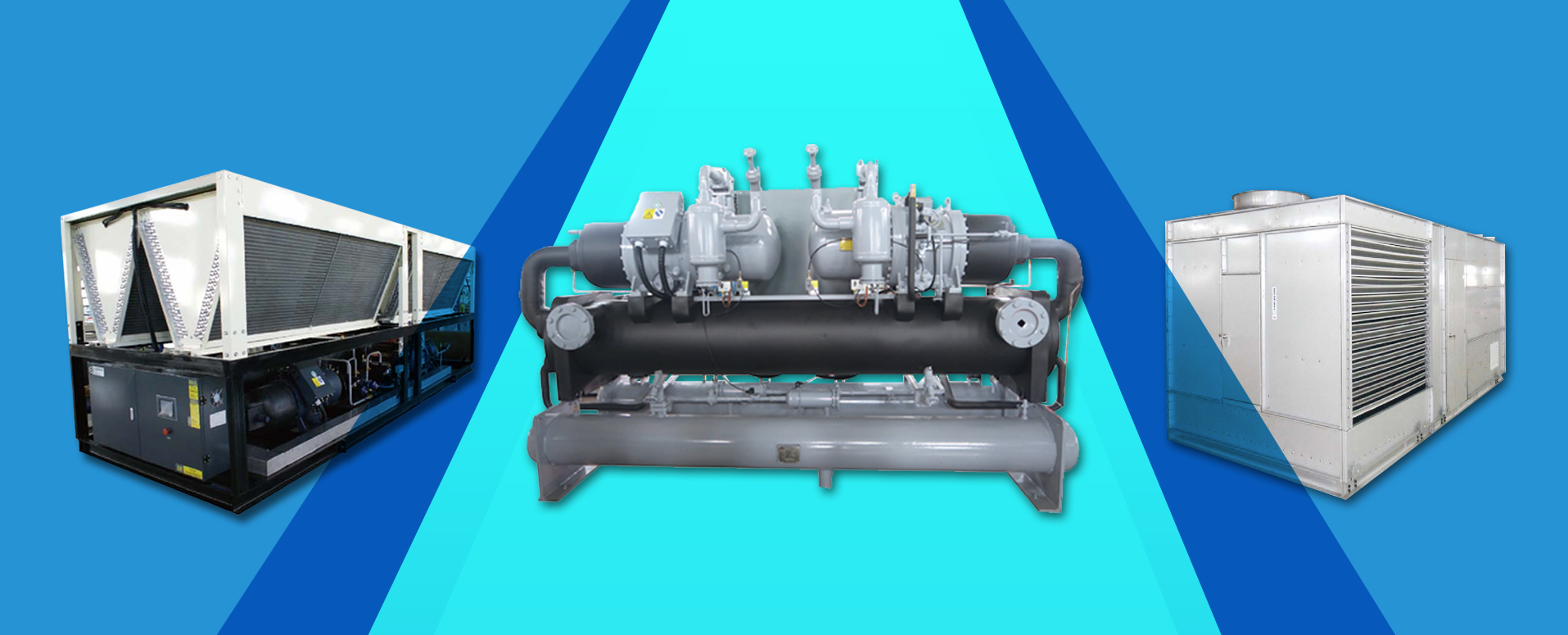

Box-type condensing unit

Description of Box-type condensing unit

Our Box-Type Condensing Units offer the perfect balance of performance and aesthetics. Featuring a weather-resistant powder-coated housing and acoustic insulation, these units run quietly and withstand the elements, making them ideal for urban installations. Pre-equipped with premium components and designed for easy service access, they ensure reliable cooling for cold rooms, convenience stores, and commercial kitchens while reducing installation labor and maintenance costs.

Characteristics of Box-type condensing unit

Aesthetic & Structural Design

· Acoustic Insulation: The interior of the casing is lined with high-density acoustic foam (egg-crate sponge) or sound-absorbing mats that significantly dampen compressor noise and vibration.

· Aerodynamic Fan Design: Utilizes low-speed, external rotor axial fans with sickle-shaped blades. These are engineered to deliver high airflow (CFM) with minimal turbulence and wind noise.

· Vibration Isolation: The compressor and motor are mounted on rubber vibration isolators to prevent noise transmission to the building structure.

High-efficiency performance

· Optimized Heat Exchange: Features a high-efficiency copper tube and aluminum fin condenser coil with a large surface area (often U-shaped or L-shaped) to maximize heat rejection, even in high ambient temperatures (up to 43°C+).

· Premium Compressors: Compatible with industry-leading compressor brands (e.g., Copeland Scroll, Bitzer, Danfoss, Panasonic) ensuring high energy efficiency ratios (EER) and reliability.

· Superior Airflow Management: The "box" design creates a directed airflow tunnel, ensuring air is pulled evenly across the entire coil surface, preventing hot spots and maintaining lower condensing pressures.

Installation and Maintainability

· Plug-and-Play Configuration: Delivered pre-piped and pre-wired. Standard units include the liquid receiver, filter drier, sight glass, solenoid valve, and pressure controls, significantly reducing on-site installation time.

· Easy Maintenance Access: Features quick-release latches or hinged service doors. Technicians can easily access the compressor, electrical box, and valves without dismantling the entire unit.

· Flexible Mounting Options: Suitable for both ground mounting (on a concrete pad) and wall mounting (using standard brackets).

Electrical and Safety Control

Integrated Electrical Box: A weatherproof (IP54/IP55) electrical control box is built into the unit, housing contactors, relays, and terminal blocks.

Comprehensive Protection:

High/Low Pressure Switches: To protect the compressor from abnormal operating pressures.

Overload Protection: Thermal protection for the fan motor and compressor.

Phase Protection (Optional): Monitors for phase loss, phase reversal, or voltage imbalance (critical for 3-phase scroll compressors).

· PrFood processing workshops

· Cold stores and freezer rooms

· Cold chain logistics centres and distribution warehouses

· Pharmaceutical factories and cleanrooms

· Biological laboratories and sample repositories

· Flower preservation chambers

· Low-temperature storage for

| Applicable Temperature(°C) | -20℃~-35℃ |

|

Refrigerant |

R22/R404A |

| Condenser Power of Fan (w) | 2*420 |

|

Length |

1360 |

| Width | 950 |

| Height | 1600 |

| Evaporation temperature: -25°C (reference) | 13490/13950 |

| Evaporation temperature: -25°C Reference power | 7880/8580 |

|

Evaporation temperature: -30°C (reference) |

10020/10520 |

|

Evaporation temperature: -30°C Reference power |

6800/7240 |

Comprehensive FAQ: Box-Type Condensing Units

Part 1: General Overview & Design

1. What exactly is a box-type condensing unit, and how does it differ from a standard open unit?

A box-type condensing unit is a refrigeration system component responsible for compressing and condensing refrigerant, housed entirely within a protective, weather-resistant enclosure (the "box").

Unlike open units, where the compressor, condenser coil, and fan are mounted on a base plate and exposed to the elements, a box-type unit encloses these components in a casing made of heavy-gauge galvanized steel with a powder-coated finish.

· Protection: The primary difference is environmental protection. The casing shields the electrical components and compressor from rain, dust, and direct sunlight, significantly extending the equipment's lifespan.

· Aesthetics: Box units are designed to look neat and professional, making them ideal for urban environments, residential areas, or visible rooftops where an industrial-looking open unit might be an eyesore.

· Noise: The enclosure acts as a sound barrier, making box-type units significantly quieter than their open counterparts.

2. What are the primary applications for box-type condensing units?

These units are highly versatile and are widely used in commercial and light industrial refrigeration. Common applications include:

· Cold Storage Rooms: Maintaining specific temperatures for food preservation (meat, vegetables, dairy).

· Convenience Stores & Supermarkets: Powering display cases, reach-in coolers, and freezers.

· Restaurant Kitchens: Walk-in freezers and coolers.

· Pharmaceutical Storage: Precise temperature control for vaccines and medicines.

· Process Cooling: Used in breweries, dairies, and industrial laser cooling systems.

They are suitable for both medium-temperature (fresh food, roughly -5°C to +5°C) and low-temperature (frozen food, roughly -18°C to -25°C) applications, depending on the compressor selection.

3. What are the key internal components included in a standard box-type unit?

While configurations vary by manufacturer, a standard high-quality box unit is a "plug-and-play" solution containing:

· Compressor: The heart of the system (Scroll, Reciprocating, or Rotary).

· Condenser Coil: Usually copper tubes with aluminum fins for heat rejection.

· Axial Fan(s): To force air through the condenser.

· Liquid Receiver: To store excess liquid refrigerant.

· Filter Drier: To remove moisture and contaminants from the refrigerant.

· Sight Glass: To visually check refrigerant level and moisture content.

· Pressure Controls: High and low-pressure switches for safety.

· Solenoid Valve: For pump-down cycles.

· Electrical Box: Containing contactors, relays, and sometimes phase protection.

4. Why are box-type units considered "low noise" or "silent"?

Noise pollution is a major concern in urban settings. Box-type units achieve low noise levels through three main engineering features:

1. Acoustic Insulation: The interior of the metal casing is often lined with sound-absorbing acoustic foam or egg-crate sponge material that dampens compressor vibration and airflow noise.

2. Fan Technology: They utilize external rotor motors or 6-pole low-speed fans with sickle-shaped blades designed to move high volumes of air (CFM) at lower RPMs, reducing wind noise.

3. Compressor Jacket: Many premium units include a dedicated sound jacket wrapped directly around the compressor body to suppress mechanical noise.

Part 2: Installation & Site Requirements

5. Can box-type condensing units be installed indoors?

While they are designed for outdoor use, they can be installed indoors, but only if specific ventilation requirements are met.

The unit rejects heat extracted from the cold room plus the heat generated by the compressor. If installed indoors without ducting, the ambient temperature in the room will rise rapidly, causing high head pressure and system failure.

· Requirement: You must use high-static pressure fans to duct the hot discharge air to the outside.

· Fresh Air: There must be an intake of fresh, cool air equal to the volume of air being exhausted.

Generally, outdoor installation (rooftops, external walls, ground slabs) is preferred to ensure unrestricted airflow.

6. What are the clearance requirements for installation?

Proper clearance is vital for heat transfer. If a unit is placed too close to a wall, it will suffer from air recirculation (sucking in its own hot discharge air).

· Air Intake Side: Needs at least 500mm to 800mm of clearance (depending on unit size) to ensure the coil gets fresh air.

· Air Discharge Side: Needs at least 1500mm to 2000mm of clearance. There should be no walls or obstacles immediately in front of the fan.

· Service Access: Ensure there is enough room for a technician to open the maintenance panels and replace a compressor if necessary.

7. How does ambient temperature affect the capacity of the unit?

Refrigeration capacity is not static; it fluctuates based on the ambient air temperature.

· Standard Rating: Most units are rated at an ambient temperature of 32°C or 35°C.

· High Ambient: If the outside temperature reaches 40°C or 45°C, the condensing pressure rises, and the cooling capacity decreases (often by 3-5% for every degree rise).

· Selection: If you are installing the unit in a tropical climate or a location with direct, intense sunlight, you must oversize the unit or select a model specifically designed for "Tropical" conditions (T3 rating) with a larger condenser surface area.

8. What are the electrical wiring requirements?

Box-type units usually require a stable power supply.

· Voltage: Single-phase (220V/50Hz) for smaller units (< 3 HP) and Three-phase (380V-415V/50Hz) for larger commercial units.

· Phase Protection: For three-phase units, a phase monitor is mandatory. It prevents the Scroll compressor from running in reverse (which destroys it) and protects against phase loss or voltage imbalance.

· Disconnect Switch: A local isolator switch should be installed within sight of the unit for safety during servicing.

Part 3: Refrigerants & Efficiency

9. Which refrigerants are compatible with modern box-type units?

Manufacturers are transitioning away from high-GWP (Global Warming Potential) refrigerants.

· Legacy (Phasing out): R22 (banned in many regions), R404A (still common but being phased down due to high GWP).

· Current Standard: R448A and R449A are popular replacements for R404A as they operate at similar pressures with a much lower GWP. R134a is common for medium temperature applications.

· Future/Natural: Some specialized box units now use R290 (Propane) or CO2, though these require specific safety components due to flammability or high pressure. Always check the compressor data plate; you cannot simply swap refrigerants without checking oil compatibility (POE vs. Mineral oil).

10. How does a Variable Frequency Drive (VFD) or Inverter improve the unit?

Standard units run at 100% speed whenever they are on. An Inverter Box-Type Unit:

· Modulates Capacity: It varies the compressor speed to match the exact cooling load. If the cold room is nearly at the setpoint, it slows down rather than stopping.

· Energy Savings: This prevents the energy spikes associated with frequent "start-stop" cycles, potentially saving 20-30% on electricity bills.

· Temperature Stability: It maintains a much tighter temperature range in the cold room, which is crucial for sensitive products like fresh produce or meat.

11. What is the function of the "Liquid Injection" feature in low-temperature units?

In low-temperature applications (freezers below -18°C), the compressor works very hard, and discharge temperatures can get dangerously hot.

Liquid Injection valves spray a small amount of liquid refrigerant directly into the compressor or the suction line. As this liquid evaporates, it cools the motor windings and the compression scroll sets. This prevents the compressor from overheating and extends the operational envelope, allowing the unit to work in hotter ambient conditions.

12. Are box-type units equipped with smart controls?

Yes, modern premium units often come with integrated electronic controllers (e.g., Dixell, Carel, or Danfoss).

· Diagnostics: They display error codes immediately (e.g., "High Pressure," "Sensor Failure"), simplifying troubleshooting.

· Networking: Some can be connected to BMS (Building Management Systems) or Wi-Fi modules for remote monitoring. A facility manager can receive an alert on their phone if the freezer unit goes offline, preventing food spoilage.

Part 4: Maintenance & Troubleshooting

13. How often should a box-type condensing unit be serviced?

To maintain efficiency and prevent failure, a preventative maintenance schedule is essential:

· Monthly: Visual check for debris blocking the airflow and check the sight glass for bubbles (indicating low charge).

· Quarterly: Clean the condenser coil. This is the most critical maintenance task.

· Annually: Comprehensive check by a certified technician, including tightening electrical connections, checking oil acidity, checking contactor condition, and verifying superheat/subcooling readings.

14. How should the condenser coil be cleaned?

A dirty condenser coil cannot reject heat, causing the compressor to draw high amps and eventually trip on high pressure.

· Method: Use a soft brush or a vacuum cleaner to remove surface dust and leaves. For deeper cleaning, use a non-acidic coil cleaner and low-pressure water.

· Caution: Do not use a high-pressure power washer directly on the fins at close range, as this can bend the aluminum fins flat, permanently ruining the airflow. Always spray parallel to the fins.

15. The unit is running, but the cold room isn't getting cold. What are the common causes?

This is a frequent issue with several potential culprits:

1. Low Refrigerant: A leak has occurred. Check the sight glass (bubbles) and low-pressure gauge.

2. Dirty Condenser: The unit cannot shed heat, so it cannot cool the refrigerant.

3. Iced Evaporator: The unit inside the room is frozen into a block of ice (due to a failed defrost heater or fan), blocking airflow.

4. Blocked Drier: If the filter drier is clogged, there will be a temperature drop across it (the outlet will be cold, possibly sweating).

16. What does it mean if the unit keeps tripping on "High Pressure" (HP)?

An HP trip is a safety mechanism to prevent the compressor from exploding. It trips when discharge pressure exceeds safety limits (e.g., 25-28 bar for R404A).

· Causes: The condenser fan motor may have failed; the condenser coil is blocked with dirt; the unit is overcharged with too much refrigerant; or non-condensables (air) are trapped in the system.

· Solution: Clean the coil, check fan operation, and purge air if necessary. Never simply bypass the HP switch.

17. How do I handle oil return issues in a box-type unit installation?

If the condensing unit is located significantly higher than the evaporator (more than 5-6 meters), oil may get trapped in the evaporator and fail to return to the compressor, leading to mechanical seizure.

· Oil Traps: You must install P-traps (oil traps) at the bottom of vertical suction risers.

· Pipe Sizing: Ensure suction lines are sized for high enough gas velocity to carry the oil back up the vertical pipe.

· Oil Separator: For long pipe runs (over 20-30 meters), installing an oil separator inside the box unit is highly recommended.

18. Why does the unit vibrate excessively?

While box units are designed to be quiet, excessive vibration indicates a problem:

· Mounting: The unit may not be level, or the rubber anti-vibration pads (isolators) under the feet are missing or worn out.

· Fan Blade: A fan blade might be unbalanced or chipped.

· Piping: Internal copper piping might be touching the casing.

· Compressor: In severe cases, internal compressor damage can cause violent shaking. Immediate inspection is required to prevent pipe fractures and leaks.

Part 5: Purchasing & Lifecycle

19. How do I select the right size box-type unit?

You cannot select a unit based solely on "Horsepower" (HP), as HP is not a precise measure of cooling capacity. Selection requires a Heat Load Calculation:

· Room Volume: Length x Width x Height.

· Insulation: Thickness and type (PU panels).

· Product Load: How much food is entering, at what temperature, and how fast it needs to cool down.

· Usage: How often the door is opened.

Once the Total Heat Load (in Watts or BTUs) is calculated, select a unit that matches that capacity at the specific evaporating and ambient temperatures of your location.

20. What is the expected lifespan of a box-type condensing unit?

With proper maintenance, a high-quality box-type unit typically lasts 10 to 15 years.

Factors that shorten lifespan include:

· Short Cycling: The compressor turning on/off too frequently (more than 6-8 times an hour).

· Overheating: consistently running with a dirty condenser.

· Corrosion: Installation in coastal areas (salty air) requires special "Blue Fin" or "Gold Fin" anti-corrosion coatings on the condenser coil to prevent rot.

Would you like me to help you calculate the heat load for a specific cold room project to determine the correct unit size?