Cold Room Condenser

Description of Cold Room Condenser

This cold storage condenser unit can be used in refrigerated rooms, fermentation chambers, hospitals, cold storage industries, milk cooling tanks, freezer rooms, cafeterias, and restaurants.

Key features of cold room condensers include: premium construction, extended service life, high capacity, compact design, user-friendly operation, innovative engineering, energy efficiency, and broad applicability.

Our products offer cold room condensers at the most competitive prices, complemented by extensive customization options.

Product Characteristics of Cold Room Condenser

Materials & Heat Exchange Technology

This is the most fundamental factor determining condenser performance. High-quality condensers typically possess the following characteristics:

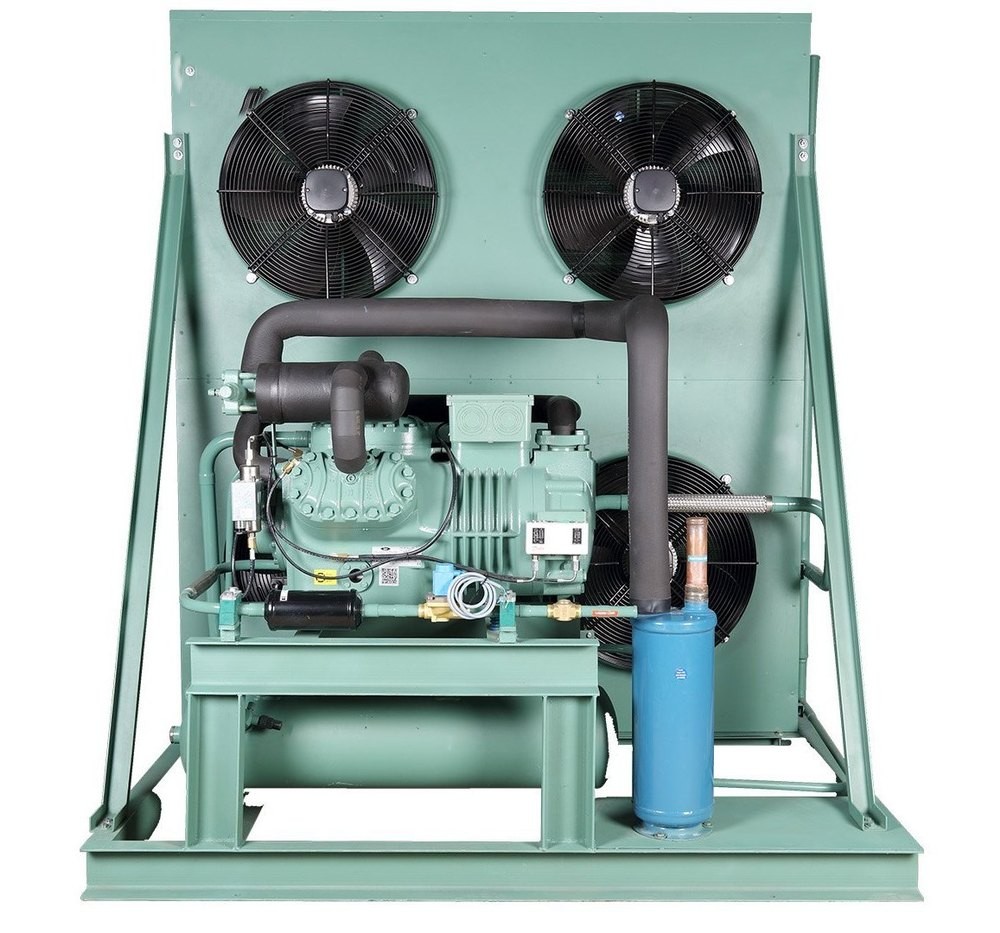

High-Efficiency Coils:

Inner-grooved Copper Tubes: Modern condensers predominantly utilise inner-grooved copper tubes over smooth-bore tubes. This design increases the internal surface area, inducing turbulence in the refrigerant flow and significantly enhancing the heat transfer coefficient.

Mechanical Expansion: Employing mechanical expansion techniques, copper tubes are tightly bonded to aluminium fins, eliminating contact thermal resistance and ensuring rapid heat transfer from the copper tubes to the fins.

Structure & Durability

Refrigeration condenser units are typically installed outdoors and must withstand harsh environmental conditions.

Robust Casing:

Galvanised Steel + Powder Coating: The casing is usually constructed from thickened galvanised steel plate, with a surface treated by high-temperature electrostatic powder coating. This process not only enhances aesthetics but, crucially, provides exceptional rust resistance, UV protection, and weatherproofing, ensuring suitability for outdoor exposure to sun and rain.

Structural Varieties:

Box Type: Compact design with side or top air discharge, suitable for small to medium-sized cold stores.

V/W-Shape: Employed for large-scale cold storage facilities. The V-shape maximises air intake area while minimising footprint, facilitating more rational airflow organisation and enhanced heat exchange efficiency

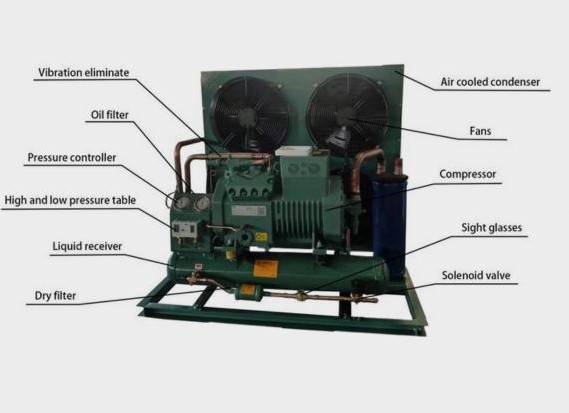

Fan Performance & Noise Control

The fan constitutes the sole moving component within the condenser, with its characteristics directly impacting both energy efficiency and potential nuisance to residents.

External Rotor Axial Fans: Modern condensers predominantly employ external rotor motors, offering compact construction, smooth operation, substantial airflow, and extended projection range.

Low Noise Operation: Optimised blade geometries (such as sickle-shaped blades) effectively reduce airflow noise. For cold storage facilities near residential areas, low-speed silent motors may be selected as an option.

High IP Rating: Considering outdoor deployment, fan motors typically feature IP54 or IP55 protection ratings, providing effective dust and water resistance. Integrated thermal protection prevents motor burnout.

Ease of Installation & Maintenance

Strict nitrogen holding pressure testing (typically at 2.5MPa - 3.0MPa) is conducted prior to dispatch to ensure leak-free performance. Units are nitrogen-charged upon leaving the factory to prevent copper tubing oxidation.

Accessible Terminal Box: An independent waterproof terminal box facilitates rapid wiring and fault diagnosis by electricians.

Hinged/Removable Panels: Side panels are designed for easy removal or hinged access, enabling cleaning personnel to perform deep cleaning of the coil.

· PrFood processing workshops

· Cold stores and freezer rooms

· Cold chain logistics centres and distribution warehouses

· Pharmaceutical factories and cleanrooms

· Biological laboratories and sample repositories

· Flower preservation chambers

· Low-temperature storage for

| Product Type |

Cold Room Condenser |

|

Weight |

250 kg |

| Certification |

ISO 9001.CE.UL |

| Voltage |

220-240V(single-phase),380-420V/Y3/50Hz(three-phase),440-480V/Y3/60Hz(three-phase) |

| Frequency |

50/60Hz |

| Phase |

3-phase/1-phase |

| Temperature |

20'℃ to -40℃ |

| Dimensions L*W*H(mm) |

Customizable (1200-2000x800-1200x600-1000 mm) |

| Refrigeartion Gas |

R22, R404,R507. R134A |

| Specification |

5HP |

| Cooling Capacity |

12,000-15,000 BTU (3.5-4.5 kW) |

| Power Consumption |

2.5-3.5 kW |

| Material |

Copper, Aluminum |

| Air Flow |

2,000-3,000 m/h |

The Complete Guide to Cold Room Condensers: 20 Frequently Asked Questions

The condenser is often the unsung hero of a commercial refrigeration system. While the evaporator keeps your products cold inside the room, the condenser does the heavy lifting of rejecting that heat to the outside world. Understanding this component is critical for facility managers, technicians, and business owners to prevent costly downtime and spoilage.

Part I: Fundamental Concepts

1. What is the specific function of a condenser in a cold storage system?

The condenser is a heat exchange device responsible for "rejecting" the heat absorbed from the cold room. In the refrigeration cycle, the compressor pumps high-pressure, high-temperature refrigerant gas into the condenser.

As the refrigerant flows through the condenser coils, it releases heat into the surrounding medium (usually air or water). This release of heat causes the refrigerant to undergo a phase change, condensing from a hot gas into a high-pressure liquid. This liquid then travels to the expansion valve and evaporator to absorb heat from the cold room again. Without a functioning condenser, the heat trapped in the refrigerant has nowhere to go, and the cooling cycle breaks down immediately.

2. What is the difference between an Air-Cooled and a Water-Cooled condenser?

This is a critical distinction based on your facility's infrastructure:

-

Air-Cooled Condensers: These are the most common in standard restaurants and small-to-medium cold storage facilities. They use fans to blow ambient air across finned coils to remove heat. They are generally easier to install, require less maintenance, and are cheaper upfront. However, their efficiency drops significantly on very hot summer days when the ambient air temperature is high.

-

Water-Cooled Condensers: These use water circulated through a pipe system to absorb heat from the refrigerant. They are typically used in large industrial plants or where ambient air circulation is poor (e.g., inside a basement). They are highly efficient regardless of outdoor air temperature but require a cooling tower or a consistent water source, making them more expensive and complex to maintain due to issues like scaling and water treatment.

3. Why are there "fins" on the condenser coils?

The copper tubing in a condenser carries the refrigerant, but a simple tube does not have enough surface area to release heat quickly. Manufacturers attach thin aluminum plates, known as fins, to the copper tubes to drastically increase the surface area.

Heat conducts from the hot copper tube into the aluminum fins. As the fan blows air across these fins, the heat is dissipated into the air much faster than it would be from the tube alone. The density of these fins (measured in Fins Per Inch, or FPI) is a balancing act; higher FPI offers more cooling surface but clogs with dust more easily.

4. Where should the condensing unit be located for optimal performance?

Location is paramount for air-cooled units. The condenser should be placed in a well-ventilated area, typically outdoors (on a roof or a ground slab) or in a large, well-vented mechanical room.

Key requirements for location include:

-

Airflow: There must be no obstructions (walls, shrubs, or boxes) within 3-5 feet of the unit to ensure air can circulate freely.

-

Temperature: It should be installed away from direct heat sources like kitchen exhaust fans or direct sunlight if possible.

-

Accessibility: Technicians must be able to reach the unit easily for cleaning and repairs. If it is mounted high on a wall without a platform, maintenance will likely be neglected.

5. What is the "Head Pressure" and why does it matter?

Head pressure refers to the pressure of the refrigerant leaving the compressor and entering the condenser (the high side of the system). It is directly related to the condensing temperature.

If the condenser is dirty or the fan is broken, it cannot reject heat effectively. This causes the pressure inside the condenser to spike (High Head Pressure). High head pressure forces the compressor to work harder, draw more amperage, and eventually overheat or trip the safety overload switch. Monitoring head pressure is the primary way technicians diagnose condenser health.

Part II: Maintenance and Cleaning

6. How often should I clean my cold room condenser coils?

Frequency depends entirely on the environment, but here is a general rule of thumb:

-

Standard Outdoor Environment: Every 3 to 6 months.

-

Grease-Heavy Environments (near kitchen exhaust): Monthly. Grease acts as a glue for dust, creating a thick blanket that blocks heat transfer.

-

High Dust/Pollen Areas (near construction or fields): Every 1 to 2 months during peak seasons.

Neglecting this schedule is the #1 cause of compressor failure. If you can see a layer of gray fuzz on the fins, you are already overdue for a cleaning.

7. What is the correct procedure for cleaning a condenser?

Proper cleaning involves more than just spraying water. Follow these steps:

-

Power Off: Always disconnect power to the unit to prevent injury from the fan.

-

Debris Removal: Remove large debris (leaves, paper) by hand or with a brush.

-

Chemical Application: Apply a non-acidic coil cleaner specifically designed for condensers. Allow it to sit and foam for 5-10 minutes to lift the dirt and grease.

-

Rinsing: Wash the solution off with low-pressure water. Never use a high-pressure power washer directly on the fins, as this can bend them flat and ruin the unit.

-

Fin Straightening: If fins are bent, use a "fin comb" to straighten them out to restore airflow.

8. Can I use a pressure washer to clean the coils?

This is a very common question, and the answer is generally NO.

While commercial pressure washers are effective at stripping dirt, the water pressure is usually too high for the delicate aluminum fins. If you blast the coils at a 90-degree angle with high pressure, you will flatten the fins against the tube. This creates a wall that air cannot pass through, effectively destroying the condenser's ability to function. Use a standard garden hose with a spray nozzle, or a specialized low-pressure coil cleaning machine.

9. What are the signs that my condenser is dirty or blocked?

You don't always need to go to the roof to know there is a problem. Watch for these symptoms inside the cold room:

-

Rising Temperatures: The room struggles to hold its set point (e.g., rising from 3°C to 7°C).

-

Continuous Running: You hear the condensing unit running non-stop without cycling off.

-

High Energy Bills: Your electricity usage spikes unexpectedly.

-

Hot Liquid Line: The copper pipe leaving the condenser (the liquid line) is extremely hot to the touch, indicating heat isn't being removed effectively.

10. Why is there grease on my condenser coils?

If your cold storage is located near a commercial kitchen, the condenser often pulls in air that contains vaporized cooking grease from exhaust vents or dumpsters.

Grease is the worst enemy of a condenser. Unlike dry dust, which can be brushed off, grease coats the fins and insulates them, preventing heat transfer. Furthermore, grease catches dust, creating a "sweater" over the unit. If grease is present, simple water will not work; you must use a degreasing coil cleaner.

Part III: Troubleshooting Common Issues

11. Why is the condenser fan making a loud noise?

Loud noises usually indicate a mechanical failure in the fan assembly. Common causes include:

-

Worn Bearings: A grinding or screeching sound suggests the fan motor bearings are drying out or failing.

-

Loose Blade: A rattling or banging sound may mean the fan blade has come loose from the motor shaft.

-

Obstruction: Sometimes, ice, wire ties, or debris (like a twig) hits the fan blade as it spins.

-

Vibration: The mounting bolts holding the motor may have vibrated loose over time.

12. What causes "Short Cycling" in relation to the condenser?

Short cycling is when the unit turns on and off rapidly (e.g., every 2 minutes). While this can be caused by thermostat issues or low refrigerant, a common condenser-related cause is the High-Pressure Cut-Out Switch.

If the condenser is extremely dirty or the fan has failed, the pressure rises rapidly as soon as the compressor starts. The safety switch trips the unit off to save the compressor. The pressure drops, the unit restarts, and the cycle repeats. This is extremely damaging to the compressor motor.

13. Why is the liquid line leaving the condenser warm/cool instead of warm?

The line leaving the condenser should typically be warm to the touch (slightly above ambient temperature).

-

If it is scorching hot: The condenser is not rejecting heat (dirty coils or broken fan).

-

If it is cool: This might indicate that the system is low on refrigerant, or it is extremely cold outside and the system lacks "head pressure controls" (see Question 17).

14. Can a condenser leak refrigerant?

Yes. Over time, the copper tubes can develop pinhole leaks due to:

-

Vibration: Constant rubbing of tubes against the metal casing.

-

Corrosion: Being located near the ocean (salt air) or in industrial areas with acidic rain can corrode the copper and aluminum (galvanic corrosion).

-

Physical Damage: Accidental impact from hail or debris.

-

Formicary Corrosion: A specific type of corrosion caused by chemical reactions with volatile organic compounds in the air.

If you see oil stains on the condenser coils, it is a strong indicator of a refrigerant leak.

15. What happens if the condenser fan motor fails?

If the fan motor dies, airflow stops. Heat transfer ceases almost immediately. The refrigerant remains a high-pressure gas rather than condensing into a liquid. The head pressure will skyrocket until the high-pressure safety switch trips the system. In systems without safety switches, the compressor will overheat and eventually burn out, leading to a repair bill that is 10x the cost of a fan motor.

Part IV: Efficiency and Technical Specs

16. What is "Subcooling" and how do I measure it at the condenser?

Subcooling is a measure of how much the liquid refrigerant has cooled below its saturation temperature (the temperature at which it turned from gas to liquid). It ensures that a solid column of liquid reaches the expansion valve.

To measure it:

-

Measure the pressure at the condenser outlet and convert it to saturation temperature using a P-T chart.

-

Measure the actual temperature of the liquid line at the condenser outlet.

-

Subtract the actual temperature from the saturation temperature.

A normal subcooling range is typically between 10°F and 15°F (5°C to 8°C). If subcooling is zero, you have gas bubbles in the line, which kills efficiency.

17. How does cold ambient weather affect the condenser?

Surprisingly, cold weather can cause problems. If it is -10°C outside, the condenser works too well. The head pressure drops so low that there isn't enough pressure to push the refrigerant through the expansion valve into the evaporator. This "starves" the evaporator.

To fix this, systems installed in cold climates need Head Pressure Controls (such as fan cycling switches or flooding valves). These controls stop the condenser fan or back up refrigerant into the condenser to artificially raise the pressure during winter.

18. What is the impact of "Fin Spacing" (FPI) on maintenance?

Fins Per Inch (FPI) dictates how tightly the fins are packed.

-

High FPI (14-16 fins/inch): More efficient heat transfer in a smaller footprint, but clogs very quickly. Not recommended for greasy or dusty environments.

-

Low FPI (8-10 fins/inch): Less efficient per square inch (requires a larger unit), but allows dust and debris to pass through more easily. These are better suited for dirty industrial environments or kitchens as they resist clogging.

19. How long does a commercial condenser typically last?

With proper maintenance, a condenser coil and unit can last 15 to 20 years. However, the individual components like fan motors and capacitors typically have a lifespan of 5 to 7 years.

Factors that shorten lifespan include:

-

Coastal locations: Salt spray can destroy a condenser in 5-7 years unless it has a special protective coating (like epoxy or polyurethane).

-

Chemical cleaners: Using acidic cleaners too frequently can eat away the aluminum fins, causing them to detach from the copper tubes.

20. When should I replace the condenser rather than repair it?

You should consider replacing the condensing unit if:

-

Multiple Leaks: If the coil is "rotten" and springing leaks in multiple places, patching is a waste of money.

-

Fin Deterioration: If the aluminum fins crumble when touched (due to corrosion), the unit can no longer transfer heat effectively.

-

Compressor Failure + Old Age: If the compressor blows on a 15-year-old unit, it is often more cost-effective to replace the whole condensing unit (condenser + compressor) rather than just the compressor, as the condenser coil is likely near the end of its life too.

-

Refrigerant Phase-Out: If you have an old unit running on banned refrigerants (like R-22), a major failure is the right time to upgrade to a modern, energy-efficient unit compatible with new refrigerants.