Fish Cold Room Temperatures

Chilling

Chilling

Freezing

Freezing

Blast Freezing

Blast Freezing

>Rapidly freezes fish at extremely low temperatures (-25°C to -40°C).

>Format smaller ice crystals and maintain texture and quality upon thawing.

>Preserving fish with minimal damage to its cellular structure.

Fishing Industry

Fishing Industry

Fish Processing Plants

Fish Processing Plants

Catering Businesses

Catering Businesses

Fish Supermarkets

Fish Supermarkets

Comprehensive Guide to Fish Cold Storage: Frequently Asked Questions

1. What is the internationally accepted standard temperature for long-term fish storage?

While -18°C (0°F) is the generally accepted international standard for frozen food storage, it is considered the maximum temperature for fish. For high-quality commercial storage, especially for fatty fish or storage exceeding 6 months, lower temperatures of -25°C to -30°C (-13°F to -22°F) are recommended. Super-frozen products (like high-grade Tuna) require -60°C (-76°F) to completely halt enzymatic activity.

2. Why is "Flash Freezing" superior to conventional home freezing?

The speed of freezing directly dictates quality. Flash freezing (or quick freezing) lowers the core temperature of the fish rapidly. This causes water molecules to form micro-crystals (tiny ice crystals).

-

Slow Freezing: Creates large, jagged ice crystals that puncture cell walls. When thawed, the cells collapse, leaking moisture (drip loss), resulting in a dry, mushy texture.

-

Flash Freezing: Creates microscopic crystals that sit inside the cells without damaging the walls, preserving the "fresh" texture and moisture upon thawing.

3. What is the "Critical Zone" in the freezing process?

The Critical Zone is the temperature range between -1°C and -5°C (30°F and 23°F). This is where the majority of the water content in the fish muscle turns into ice. The goal of any efficient cold storage operation is to pass the fish through this zone as quickly as possible (ideally in under 2 hours) to prevent large crystal formation.

4. Does freezing kill bacteria and parasites?

-

Bacteria: Freezing does not kill bacteria; it puts them into a dormant state. Once thawed, bacteria will wake up and multiply just as fast (or faster) than before.

-

Parasites: Yes, freezing can kill parasites (like nematodes), but strict time/temperature protocols must be met (e.g., freezing and storing at an ambient temperature of -20°C or below for 7 days, or freezing at -35°C or below until solid and storing at -35°C or below for 15 hours).

5. What is "Freezer Burn," and what actually causes it scientifically?

Freezer burn is essentially sublimation. This is a physical phase transition where ice turns directly into water vapor without becoming liquid first. In the dry environment of a freezer, moisture on the surface of the fish evaporates into the air. This leaves behind dehydrated, oxidized protein structures that appear white/grey and leathery. It is not dangerous to eat, but it ruins the texture and flavor.

6. What is "Rigor Mortis," and how does it affect freezing?

Rigor mortis is the stiffening of muscles after death.

-

Pre-Rigor: Freezing fish before rigor sets in is ideal for freshness, but if thawed too quickly, it can cause "thaw rigor," where the muscle contracts violently, losing moisture.

-

In-Rigor: Freezing rigid fish is difficult and can damage the meat if forced flat.

-

Post-Rigor: This is acceptable, but the fish is slightly less fresh than pre-rigor stock.

-

Gaping: Freezing fish improperly during rigor can cause the connective tissue to break, leading to fillets falling apart (gaping).

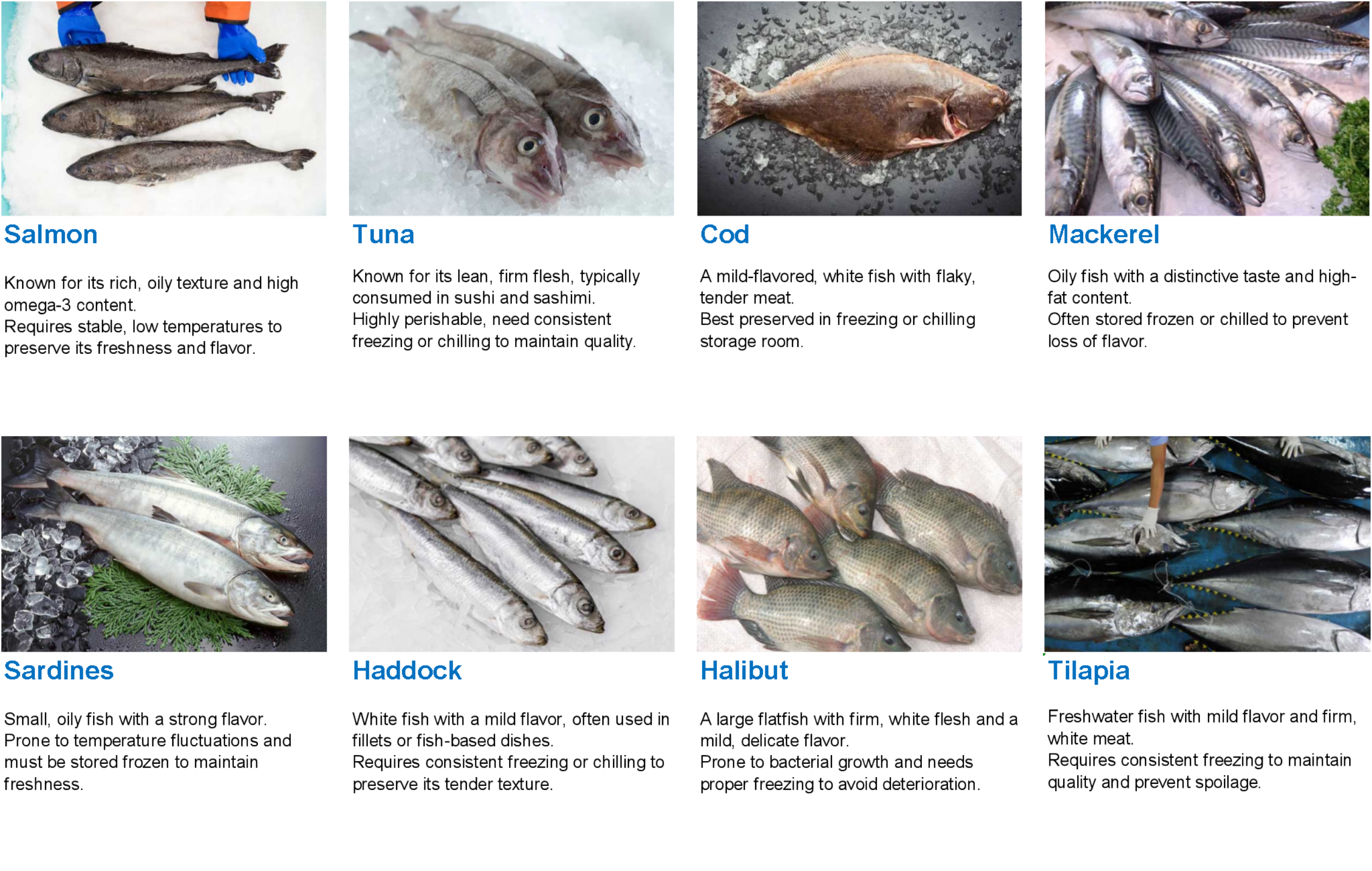

7. How does fat content influence storage life?

Fat is the limiting factor in frozen fish shelf life. Even at freezing temperatures, fats react with small amounts of oxygen (oxidation).

-

Lean Fish (Cod, Haddock, Pollock): Store well for 12+ months because they have little fat to go rancid.

-

Fatty Fish (Salmon, Mackerel, Sardines): Have a shelf life of only 3–6 months at standard -18°C because their polyunsaturated fats oxidize quickly, leading to a yellow appearance and rancid taste.

8. Why is bleeding (exsanguination) critical before freezing?

Blood is a catalyst for spoilage. It contains iron (heme), which accelerates lipid oxidation (rancidity), and it provides a medium for bacterial growth. Thoroughly bleeding a fish immediately after catching results in a whiter fillet, a cleaner taste, and a significantly longer frozen shelf life.

9. Is it necessary to gut (eviscerate) fish before cold storage?

Yes. The digestive tract contains powerful enzymes (digestive juices) and high bacterial loads. If left inside, these enzymes can eat through the stomach wall (belly burn) and taint the meat, even while frozen, causing a bitter taste and soft texture.

10. What is "Hydro-cooling," and why is it done before freezing?

Hydro-cooling is the process of immersing fish in chilled water (often seawater slurry) immediately after catch to lower its temperature to near 0°C before it enters the freezer. This reduces the thermal load on the freezer and ensures the fish passes through the "Critical Zone" faster.

11. Should fish be scaled before freezing?

It depends on the end use. Scaling is generally easier on fresh fish. However, leaving scales on can act as a natural "shield" against freezer burn and physical damage during handling. Most commercial fillets are descaled, while whole fish are often frozen with scales on.

12. What is the "Deep Skinning" method?

For fatty fish, the layer of fat directly under the skin is the most prone to oxidation. "Deep skinning" removes the skin and the subcutaneous fat layer. While this reduces yield, it significantly extends the shelf life of the frozen fillet by removing the most volatile fats.

13. What is a Blast Freezer (Air Blast Freezer)?

A blast freezer uses high-velocity fans to blow extremely cold air (-35°C to -40°C) over the fish. It is the most common commercial method. The moving air strips heat away from the product much faster than static air (convection), ensuring rapid freezing.

14. What is a Plate Freezer (Contact Freezer)?

Plate freezers consist of hollow metal plates with refrigerant flowing through them. Fish blocks or boxes are sandwiched between these plates.

-

Advantage: Extremely fast heat transfer via conduction; creates perfectly flat, uniform blocks that are easy to stack and palletize.

-

Usage: Common on fishing trawlers and for making fish sticks/blocks.

15. What is Cryogenic Freezing?

This method sprays liquid nitrogen (–196°C) or carbon dioxide directly onto the fish. It provides the fastest possible freezing rate, resulting in the highest quality texture. However, it is very expensive and typically reserved for high-value items like shrimp, scallops, or sushi-grade fillets.

16. What is IQF (Individually Quick Frozen)?

IQF involves freezing pieces of fish (like shrimp or scallop meat) separately on a conveyor belt so they do not stick together.

-

Benefit: The consumer can defrost exactly the amount needed (e.g., 5 shrimp) rather than defrosting a solid 5lb block.

17. What is the function of a "Cold Store" vs. a "Freezer"?

-

Freezer: A machine designed to remove heat and change the state of the product from unfrozen to frozen.

-

Cold Store: A warehouse designed only to maintain the temperature of already frozen goods. Putting warm fish into a cold store will fluctuate the room temperature and damage other stock.

18. How do "Air Curtains" protect cold storage?

Air curtains (or air doors) blow a high-velocity stream of air downwards at the warehouse entrance. This creates an invisible barrier that prevents cold air from escaping and warm, humid air from entering when the doors are opened for forklifts, preventing ice buildup on the cooling coils.

19. What is "Glazing," and how is it calculated?

Glazing is the application of a protective layer of ice to the surface of frozen fish. The fish is frozen, dipped in cold water, and refrozen.

-

Purpose: The ice layer prevents air from reaching the fish skin (stopping oxidation) and sacrifices itself to evaporation (stopping freezer burn).

-

Calculation: It is usually expressed as a percentage of the total weight (e.g., 10% glaze). Buyers must know if the price is "Net Weight" (fish only) or "Gross Weight" (fish + ice).

20. What is Modified Atmosphere Packaging (MAP)?

MAP involves replacing the air inside a package with a specific gas mixture (usually Carbon Dioxide, Nitrogen, and low Oxygen).

-

Freezing Context: While common for fresh fish, MAP is also used for frozen fish to prevent oxidation without vacuum squeezing the product.

21. Why is Vacuum Skin Packaging (VSP) considered the Gold Standard?

VSP heats a plastic film and drapes it over the fish, using a vacuum to pull it tight like a second skin. It eliminates almost all oxygen, prevents ice crystal formation on the surface, and prevents the packaging from wrinkling (which can collect frost).

22. What are Polybags and Interleaving?

-

Polybags: Individual plastic bags for whole fish or fillets.

-

Interleaving: Placing sheets of plastic (PE) or wax paper between fillets in a "shatterpack." This allows workers to separate frozen fillets without thawing the whole box.

23. Can cardboard boxes be used in cold storage?

Yes, but they must be "wax-impregnated" or coated with polyethylene. Standard cardboard absorbs moisture from the humid freezer air, loses structural integrity, and collapses, potentially causing stacks to fall.

24. What is the role of antioxidants in frozen fish storage?

For industrial storage of fatty fish (like minced mackerel), natural antioxidants (like Rosemary extract) or synthetic ones may be added before freezing to delay the onset of rancidity in the fats.

25. Why does frozen Tuna turn brown?

Tuna meat is red due to Myoglobin. When myoglobin oxidizes, it turns into Metmyoglobin, which is brown.

-

Prevention: This is why Tuna requires super-freezing at -60°C. At standard -18°C, the chemical reaction that turns red to brown still occurs, just slowly.

26. What causes "Black Spot" (Melanosis) in shrimp?

Melanosis is an enzymatic reaction causing harmless but unsightly black spots on the shell and meat of shrimp. It is triggered by oxygen and enzymes. Freezing slows it down, but sulfites are often used as a dip before freezing to prevent it entirely.

27. Why does frozen Salmon sometimes develop "white stuff" on the surface?

This is often Albumin, a protein that coagulates and squeezes out of the muscle fibers if the fish is cooked too fast or was frozen slowly. If it appears on raw frozen fish, it is likely severe freezer burn.

28. What is "Gaping"?

Gaping is when the flakes of the fish fillet separate, leaving holes or slits.

-

Cause: It is caused by rough handling of the fish while it was in rigor mortis, or by freezing the fish too slowly, causing large ice crystals to rupture the connective tissue (collagen) holding the flakes together.

29. Why does Hake or Pollock sometimes become "spongy"?

This is caused by the denaturation of proteins due to prolonged storage or fluctuating temperatures. The protein structure changes and cannot hold water anymore, resulting in a texture like a dry sponge.

30. What is "Chalky Halibut"?

This is a condition where the flesh is opaque, white, and soft. It is related to the pH levels and lactic acid accumulation in the fish at the time of death. It is not caused by freezing, but freezing makes the visual defect more obvious.

31. What is the "Cold Chain"?

The cold chain is the uninterrupted series of storage and distribution activities which maintain a given temperature range. If a truck breaks down or a pallet sits on a loading dock for an hour (breaking the chain), the shelf life of the fish is permanently reduced, even if refrozen.

32. What does FIFO vs. FEFO mean in fish inventory?

-

FIFO (First In, First Out): Using the stock that arrived earliest.

-

FEFO (First Expired, First Out): Using the stock with the closest expiration date.

-

Relevance: In fish storage, FEFO is often safer because different batches may have different shelf lives depending on how they were handled before freezing.

33. How should pallets be stacked in a cold room?

Pallets must not block the airflow from the evaporators (fans). There should be gaps between pallets and walls to allow cold air to circulate. If air cannot circle the pallet, the center of the pallet ("the thermal center") may remain warm, causing spoilage.

34. What is a "Data Logger"?

A small electronic device placed inside fish shipments that records the temperature at set intervals (e.g., every 15 minutes). It proves that the fish remained frozen during transit. If the logger shows a spike to 0°C, the shipment may be rejected.

35. How do you handle "Drip Loss" economically?

Drip loss represents lost weight and therefore lost money. To minimize this, the industry uses moisture-retention agents (like phosphates) within legal limits, or ensures rapid freezing technologies are used to minimize cellular damage.

36. Why is thawing in a vacuum bag risky for some species?

While rare, the bacteria Clostridium botulinum (Botulism) is anaerobic (loves oxygen-free environments) and can grow at temperatures above 3.3°C. If you thaw vacuum-packed fish in warm water or on a counter, you create a perfect environment for toxin production.

-

Solution: always break the vacuum seal before thawing, or keep the temp strictly below 3°C.

37. Can you cook fish from frozen?

Yes, particularly thin fillets or breaded portions. However, for thick steaks or whole fish, cooking from frozen is risky because the outside will overcook/burn before the internal temperature reaches the safe zone (63°C/145°F).

38. What is "Slacking" or "Tempering"?

In industrial processing, "slacking" is raising the temperature of deep-frozen fish (from -25°C) to just below freezing (e.g., -4°C). The fish is still firm but not rock hard. This allows saws and blades to cut the fish into portions without shattering the meat or breaking the blades.

39. How do you identify "Temperature Abuse"?

Signs include:

-

Ice crystals inside the package: Indicates the fish thawed and released water, which then refroze as frost.

-

Distorted shape: The box or fish is bent, indicating it softened and was squashed.

-

Purge: Excessive blood/water frozen at the bottom of the bag.

40. What is Scombroid Poisoning (Histamine Toxicity)?

This occurs in fish like Tuna, Mackerel, and Mahi-Mahi. If the fish gets warm before freezing, bacteria convert histidine (an amino acid) into histamine.

-

Crucial Fact: Freezing prevents new histamine from forming, but it does not destroy histamine already present. Even cooking does not destroy it. Cold chain discipline before freezing is the only prevention.

41. Can you refreeze thawed fish?

-

Safety perspective: Yes, if it was thawed in a refrigerator and never exceeded 4°C.

-

Quality perspective: No. Refreezing creates a second round of ice crystal formation, usually larger than the first, which destroys the texture. The fish will be dry and tasteless.

42. How do you remove "fishy smells" from a cold storage facility?

Use an ozone generator (O3) or perform a deep clean with alkaline detergents followed by sanitizers. Ensure drainage channels are clear, as fish blood in drains is the primary source of odor.

43. What is HACCP in the context of frozen fish?

Hazard Analysis Critical Control Points. It is a management system where food safety is addressed.

-

CCP for Freezing: The freezing step itself is often a Critical Control Point to stop bacterial growth.

-

CCP for Parasites: The duration and temperature of freezing is a CCP for parasite destruction.

Время публикации:Sep-25-2020