-

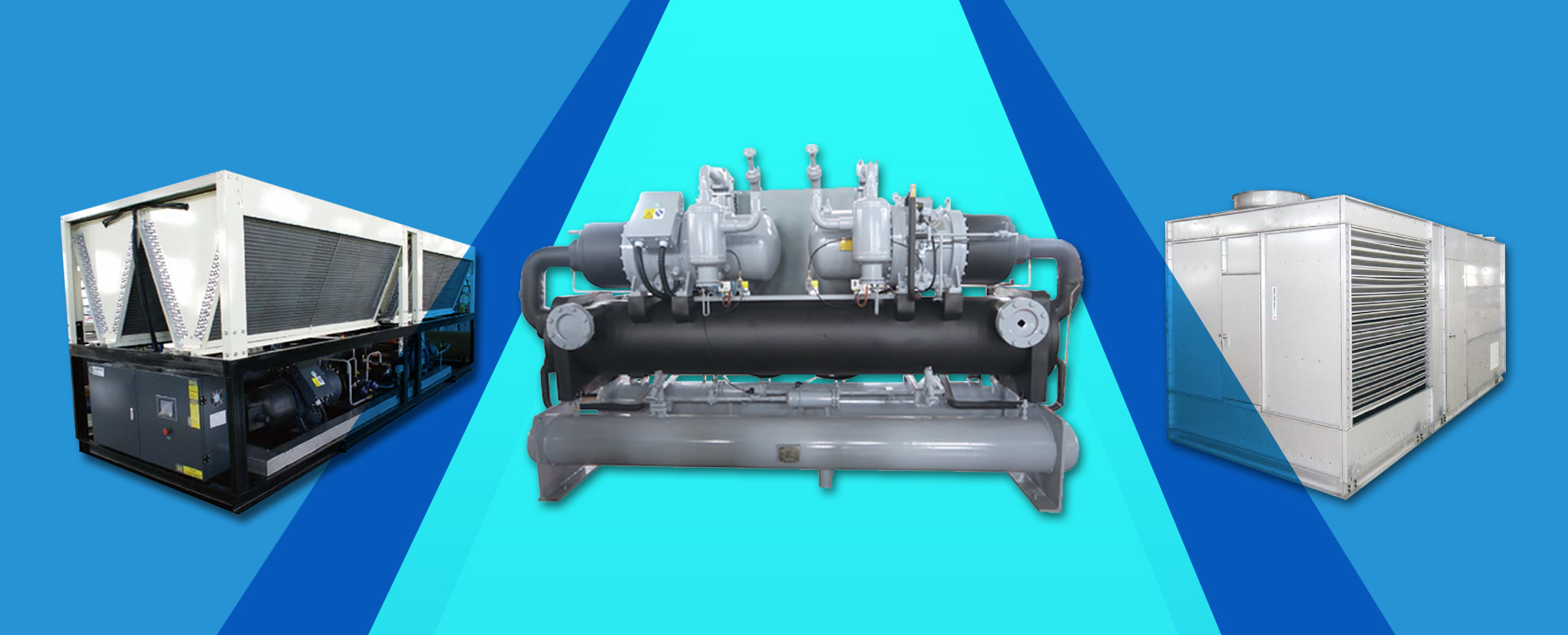

CWZ490 Medium-Low Temperature Screw Chiller Units

-

CWZ460D Medium-Low Temperature Screw Chiller Units

-

CWZ460 Medium-Low Temperature Screw Chiller Units

-

CWZ420D Medium-Low Temperature Screw Chiller Units

-

CWZ420 Medium-Low Temperature Screw Chiller Units

-

CWZ390D Medium-Low Temperature Screw Chiller Units

-

CWZ380 Medium-Low Temperature Screw Chiller Units

-

CWZ360D Medium-Low Temperature Screw Chiller Units

-

CWZ290 Medium-Low Temperature Screw Chiller Units

-

CWZ345 Medium-Low Temperature Screw Chiller Units

-

CWZ320 Medium-Low Temperature Screw Chiller Units

-

CWZ290D Medium-Low Temperature Screw Chiller Units

1. Product Overview

Medium-to-low temperature screw chillers are highly efficient refrigeration units specifically engineered for industrial freezing, food processing, and specialised process cooling applications. This series employs semi-hermetic or hermetic screw compressors as its core power source, delivering stable cooling within the range of -40°C to +5°C through advanced control systems.

Distinct from standard air-conditioning chillers, this product undergoes specialised optimisation for low-temperature applications. It maintains exceptional Coefficient of Performance (COP) even under high compression ratios, serving as an ideal modern solution to replace traditional ammonia units and outdated reciprocating compressors.

2. Key Specifications

Refrigerants: Environmentally friendly R404A, R507, R410A, R134a, R22 (optional)

Secondary Coolant: Ethylene glycol solution (Glycol), calcium chloride brine, other antifreeze solutions

Outlet Water Temperature Range:

Medium-Temperature Type: -5°C to +5°C (Suitable for preservation, process cooling)

Low-Temperature Type: -20°C to -35°C (Suitable for freezing, crystallisation)

Ultra-Low Temperature Type: -35°C to -45°C (Suitable for quick-freezing, specialised chemical processing)

Refrigeration Capacity Range: 50kW - 2000kW (Customisable to client requirements)

Power Supply Configuration: 380V/50Hz/3Ph (Standard), Customisable to 440V/60Hz etc.

3. Key Features and Technical Advantages

3.1 Robust ‘Heart’: Dedicated Screw Compressors

Optimised for Low-Temperature Operation: Utilises low-temperature-specific twin-screw compressors from Hanbell, Bitzer, or other internationally renowned brands.

Economiser System: Standard economiser interface significantly enhances refrigeration capacity (by approx. 20%-30%) and energy efficiency ratio in low-temperature conditions via subcooling circulation.

Stepless Regulation: Features 25%-100% continuous capacity modulation, precisely matching actual load to prevent frequent start-stops, thereby saving energy and extending service life.

3.2 High-Efficiency Heat Exchange System

Evaporator: Utilises dry-type or flooded shell-and-tube heat exchangers. Internally, copper tubes undergo enhanced treatment for corrosion resistance, with optimised flow channels for high-viscosity secondary refrigerants (e.g., ethylene glycol) to minimise pressure loss.

Condenser: Features high-efficiency externally threaded copper tubes offering extensive heat dissipation area, superior heat exchange efficiency, and ease of cleaning and maintenance.

3.3 Intelligent Control and Safety Protection

Microprocessor-based fully automatic control: Equipped with PLC or microcontroller, enabling one-touch operation and real-time monitoring of inlet/outlet water temperature, pressure, current, and other parameters.

Multi-level protection: Includes high/low pressure protection, anti-freeze protection, oil level protection, phase loss/reverse phase protection, overload protection, and discharge superheat protection, ensuring safe operation under adverse conditions.

3.4 Comprehensive Oil Management

Under low-temperature conditions, efficient oil return is critical for system stability. This unit incorporates a high-efficiency oil separator (oil separation efficiency >99.9%) and a precision oil cooling system, ensuring optimal compressor lubrication even at sub-zero temperatures.

Отправьте ваше Сообщение

Свяжитесь с нами. Мы готовы помочь вам.