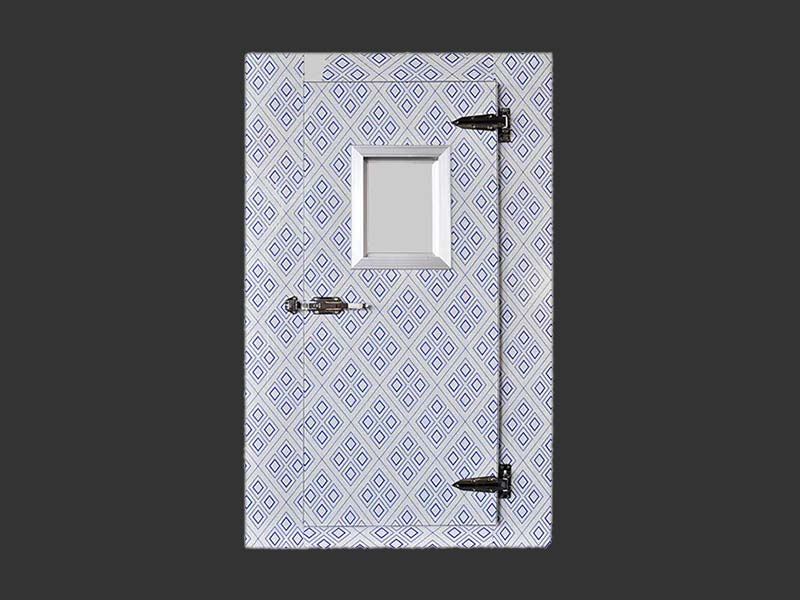

Cold storage door

Description of Cold Storage door

Cold storage panels are sandwich-structured composite panels featuring double-sided colour-coated steel or stainless steel facings with a high-density polyurethane core. They achieve tight jointing through built-in eccentric hook fasteners, offering exceptional thermal insulation properties. These panels are specifically designed for constructing cold storage facilities across various temperature grades.

Core characteristics of cold storage door

High-efficiency insulated door panels

The door panels feature a high-density polyurethane (PU) high-pressure foam moulded in one piece, offering low thermal conductivity and exceptional insulation performance. Available thicknesses (e.g., 100mm/150mm) effortlessly accommodate diverse temperature control requirements, from fresh-keeping chambers to ultra-low temperature freezers (-45°C).

l Professional-Grade Sealing System

Perimeter door seals employ low-temperature resistant, anti-ageing EPDM rubber gaskets. Combined with specially engineered door frames, these create a perfect airtight cavity upon closure, effectively preventing cold air leakage and heat ingress.

l High-Performance Track System:

Features high-strength aluminium alloy tracks with robust load-bearing capacity. Surfaces undergo anodised treatment for corrosion resistance and wear durability. Paired with silent nylon rollers, these tracks enable smooth, quiet manual or automatic operation even for heavy doors.

l Robust and Durable Construction

Door panel surfaces can be finished in colour-coated steel, stainless steel, or similar materials, offering not only aesthetic appeal but also impact resistance, corrosion resistance, and ease of cleaning. The scientifically engineered overall structure ensures minimal deformation under prolonged, high-intensity use.

· PrFood processing workshops

· Cold stores and freezer rooms

· Cold chain logistics centres and distribution warehouses

· Pharmaceutical factories and cleanrooms

· Biological laboratories and sample repositories

· Flower preservation chambers

· Low-temperature storage for

| Product Type |

Cold storage door |

|

Door Type |

Sliding |

|

Opening Type |

Induced |

|

Color |

White (customizable) |

|

Surface Finishing |

Finished, Powder Coated |

|

Size |

Standard: 1200x2000mmto 3000x4000mm(Customized sizes available) |

|

Door Panel Thickness |

100mm (3.94in),120mm(4.72in),150mm (5.91in), 200mm (7.87in)Polyurethane (PU) foam insulation |

|

Insulation Material |

Polyurethane (PU) foam insulation |

|

Temperature Range |

-40'℃ to 0'℃ (-40°F to 32°F) |

|

Specification |

Customized Available |

|

Frame Material |

Galvanized Steel/Stainless Steel |

|

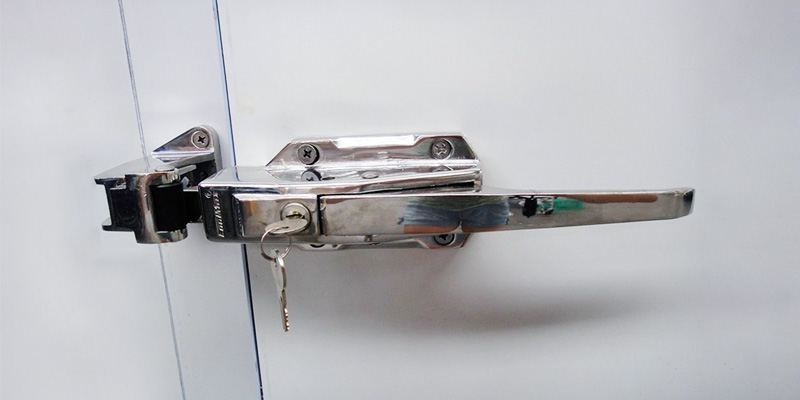

Security Features |

Lock: Electronic/Mechanical |

|

Observation window |

For observing situation inside cold room (Optional) |

A Comprehensive FAQ Guide to Cold storage door

1. What exactly is a Cold storage door?

A cold room door is a specialized, highly insulated door designed specifically for refrigerated and freezer environments. Its primary function is to create a robust thermal barrier between the controlled, cold interior and the ambient, warmer exterior. Unlike a conventional door, it features a thick core of insulating material (like polyurethane foam), heavy-duty gaskets to create an airtight seal, and often includes features like frame heaters to prevent ice formation. It is engineered for durability, energy efficiency, and operational safety in sub-zero conditions.

2. Why can't I just use a heavy-duty regular door for my cold room?

Using a regular door for a cold room would be a costly mistake for several reasons. Firstly, it lacks the necessary insulation (R-value), leading to massive energy loss as your refrigeration system works overtime to combat the constant heat ingress. Secondly, it will not create an airtight seal, allowing warm, moist air to enter, which causes condensation and dangerous ice buildup on floors, walls, and the door itself. Thirdly, standard door materials are not designed for cold temperatures and can become brittle, warp, or corrode, leading to premature failure and safety hazards.

3. What are the main types of cold room doors available?

There are three primary categories of cold room doors, each suited for different applications:

-

Hinged (or Swing) Doors: These operate like a standard residential door, swinging open and closed on hinges. They are ideal for pedestrian access, smaller walk-in coolers and freezers, and areas with limited side-to-side clearance but ample swing space. They typically provide an excellent seal when closed.

-

Sliding Doors: These doors move horizontally along a track system, either manually or automatically. They are the preferred choice for larger openings, high-traffic areas, and environments where forklifts or pallet jacks are used, as they don't require floor space to swing open.

-

High-Speed Doors: These are typically flexible, fabric-based roll-up or bi-parting doors designed for rapid opening and closing cycles. They are used in high-traffic industrial settings to minimize the time the doorway is open, drastically reducing energy loss and temperature fluctuations. They are often installed in conjunction with a more secure, insulated sliding door.

4. How do I choose between a hinged and a sliding door?

The decision depends on three key factors: traffic, space, and opening size.

-

Traffic: For personnel-only access or infrequent use, a hinged door is often sufficient and more cost-effective. For frequent traffic, especially involving machinery like forklifts, a sliding door (preferably automated) is far more efficient and safer.

-

Space: A hinged door requires clear floor space equal to its width for the swing arc. If this space is obstructed or needed for storage/movement, a sliding door is the only practical solution as it moves parallel to the wall.

-

Opening Size: Hinged doors become impractical and structurally difficult to manage for very large openings. Sliding doors are the standard for wide or tall doorways needed for vehicle or large pallet access.

5. What is "R-value" and why is it so important for a cold room door?

"R-value" is a measure of thermal resistance; the higher the R-value, the better a material's ability to insulate and resist heat transfer. For a cold room door, a high R-value is critical. It signifies that the door's insulating core (usually polyurethane foam) is effective at keeping the cold air in and the warm air out. A door with an inadequate R-value will act as a weak point in the cold room's thermal envelope, leading to higher energy consumption, increased operational costs, and difficulty in maintaining the target temperature. Freezer doors require a significantly higher R-value than cooler doors.

6. Why do some freezer doors have heaters built into the frame and threshold?

Heaters are an essential feature for doors installed on freezer rooms (operating below 0°C or 32°F). When warm, moist ambient air comes into contact with the cold surfaces of the door frame and threshold, the moisture condenses and freezes, creating ice. This ice buildup can prevent the door from sealing properly, leading to energy waste. In severe cases, it can freeze the door shut, creating a serious safety hazard. Low-wattage heater wires embedded in the door frame and sometimes the threshold gently warm the surfaces just enough to prevent condensation and ice formation, ensuring a proper seal and safe operation.

7. What are the most common materials used to construct cold room doors?

The surface materials, or "skins," of a cold room door are chosen for durability, hygiene, and corrosion resistance. Common options include:

-

Painted or Galvanized Steel: A cost-effective and durable option suitable for general-purpose applications.

-

Stainless Steel: The premium choice for food processing, pharmaceutical, and cleanroom environments due to its superior corrosion resistance, durability, and ease of sanitation.

-

Fiberglass Reinforced Plastic (FRP) or Glass Reinforced Polyester (GRP): These composite materials are extremely durable, lightweight, resistant to dents, scratches, and harsh chemicals, making them ideal for high-abuse environments.

8. What safety features are essential for a walk-in cold room door?

Safety is paramount. Essential features include:

-

Internal Safety Release: This is a legal requirement in many regions. It's a mechanism (like a push knob or handle) on the inside of the door that allows it to be opened from the inside at all times, even if it's locked from the outside. This prevents accidental entrapment.

-

Heated Viewports (Windows): For visibility to prevent collisions, especially in high-traffic areas. The heating element prevents fogging and icing.

-

Safety Sensors: For automated doors, photo-eye sensors or motion detectors are crucial to reverse the door's closing motion if an obstruction (a person or forklift) is detected.

-

Warning Lights and Alarms: These can signal when a door is opening, closing, or has been left open for too long.

9. Can cold room doors be automated?

Yes, absolutely. Automation is highly recommended for high-traffic areas. Sliding and high-speed doors are commonly automated. Actuators can include push buttons, pull cords, motion sensors, or floor-loop detectors that sense the presence of a forklift. Automation improves workflow efficiency, reduces the chance of the door being damaged by impact, and significantly enhances energy efficiency by ensuring the door is closed promptly after passage.

10. What is a "thermal break" and why is it needed?

A "thermal break" is a component made of a material with low thermal conductivity that is placed between the interior and exterior metal skins of the door frame (and sometimes the door panel itself). Metal is an excellent conductor of heat. Without a thermal break, the metal frame would act as a bridge, transferring heat from the outside to the inside and cold from the inside to the outside, leading to condensation and frost on the external frame. The thermal break, often made of a polymer or composite, effectively "breaks" this thermal bridge, improving insulation and preventing condensation.

11. How do I determine the correct size for my cold room door?

The size of the door opening, known as the "clear opening," should be based on the largest item that will pass through it. For pedestrian traffic, a standard width is usually sufficient. For pallet jacks or carts, ensure the opening is wide and tall enough to pass through without collision. For forklift traffic, the opening must accommodate the forklift's dimensions plus a safe margin of clearance on all sides. Always measure the clear opening you need, not the overall panel size.

12. What kind of regular maintenance do these doors require?

Regular maintenance is crucial for longevity and performance. Key tasks include:

-

Gasket Inspection: Regularly check gaskets for tears, cracks, or compression. A damaged gasket is a primary source of energy loss. Clean them weekly.

-

Hardware Check: Inspect and tighten all hinges, handles, rollers, and fasteners. Lubricate moving parts as recommended by the manufacturer.

-

Track Cleaning (for sliding doors): Keep the floor and overhead tracks clear of debris, ice, and dirt to ensure smooth operation.

-

Heater Functionality: In freezer applications, periodically check that the frame heaters are working correctly. A cold frame during operation indicates a potential failure.

-

Safety Feature Tests: Regularly test the internal safety release and any automated safety sensors to ensure they are functioning perfectly.

13. How can I improve the energy efficiency of my existing cold room door?

If replacing the door isn't an option, you can still improve efficiency.

-

Replace Worn Gaskets: This is the single most effective and low-cost upgrade. Ensure the new gaskets create a complete, airtight seal.

-

Install Strip Curtains: Adding PVC strip curtains inside the doorway creates a secondary thermal barrier that reduces air exchange when the main door is open.

-

Adjust Door Closers: For hinged doors, ensure the self-closing mechanism is properly adjusted to close and latch the door securely every time.

-

Implement a "Door Closed" Policy: Train staff on the importance of keeping the door closed as much as possible to minimize energy waste.

14. What are some common problems and how can I troubleshoot them?

-

Problem: Ice buildup around the frame.

-

Cause: The frame heater has failed, or the gasket is not sealing correctly, allowing moist air in.

-

Solution: Test the heater for electrical continuity. Inspect and replace the gasket if damaged.

-

-

Problem: Door is hard to open or close.

-

Cause: For sliding doors, there could be ice or debris in the track, or the rollers are worn. For hinged doors, the hinges may be misaligned.

-

Solution: Clean the track thoroughly. Inspect and replace rollers. Check and adjust hinges.

-

-

Problem: Condensation on the outside of the door.

-

Cause: This suggests a failure in the door's insulation or a compromised thermal break in the frame, allowing cold to transfer to the outer surface.

-

Solution: This may indicate the door is nearing the end of its life. A professional inspection is recommended.

-

15. What is a high-speed cold room door and when is it necessary?

A high-speed door is an automated, lightweight door that opens and closes in seconds. They are essential for high-volume operations where a doorway is used dozens or hundreds of times a day. While their insulation is lower than a traditional sliding door, their rapid cycle time means the doorway is open for a much shorter period. This drastically reduces air infiltration, prevents temperature fluctuations, controls humidity, and improves productivity by not slowing down traffic flow.

16. Are there fire-rated cold room doors?

Yes, fire-rated cold room doors are available for applications where a wall is part of a building's fire-containment system. These doors are specially constructed and tested to meet specific fire-resistance ratings (e.g., 60, 90, or 180 minutes). They combine the thermal insulation properties of a cold room door with the fire-retardant and structural integrity requirements of a fire door, often featuring automatic closing mechanisms that are triggered by a fire alarm system.

17. How does the operating temperature (chiller vs. freezer) affect the door choice?

The operating temperature is a primary factor in door selection.

-

Chillers/Coolers (above 0°C / 32°F): Doors for these environments require good insulation (e.g., 80mm-100mm thick) but typically do not need frame heaters.

-

Freezers (below 0°C / 32°F): Doors for freezers require superior insulation (e.g., 100mm-150mm thick or more) to achieve a higher R-value. They absolutely require heated frames and thresholds to prevent the door from freezing shut. The hardware and lubricants used must also be rated for sub-zero operation.

18. What is the typical lifespan of a cold room door?

The lifespan of a cold room door depends heavily on the quality of manufacturing, the intensity of use, and the consistency of maintenance. A well-maintained, high-quality door in a light-use environment could last 15-20 years or more. In a high-traffic, heavy-abuse industrial setting, even a robust door may need significant repairs or replacement within 7-10 years. Regular maintenance is the key to maximizing its operational life.

19. How is a cold room door installed, and should I do it myself?

Installation is a precise process that involves securely mounting the frame to the wall panels, ensuring it is perfectly plumb and level. The door panel is then hung and adjusted to create a perfect seal with the gaskets. For automated doors, electrical wiring for motors, sensors, and heaters is also required. Unless you have specific experience with cold room construction, it is highly recommended to have the door installed by qualified professionals. Improper installation can lead to poor sealing, energy loss, operational problems, and can even void the manufacturer's warranty.

20. What should I look for in a cold room door supplier or manufacturer?

When choosing a supplier, consider the following:

-

Quality of Materials and Construction: Look for manufacturers who use high-density polyurethane foam, robust hardware, and high-grade finishing materials.

-

Customization Options: A good supplier can build a door to your exact size, temperature, and operational requirements.

-

Technical Support and Warranty: Ensure they offer strong technical support and a comprehensive warranty on their products.

-

Industry Experience and Reputation: Choose a company with a proven track record in the cold storage industry. Check for reviews, case studies, and references.

-

Compliance and Certifications: Verify that their products meet relevant safety and hygiene standards (e.g., NSF for food environments).