Cold Room

Description of the Cold Room

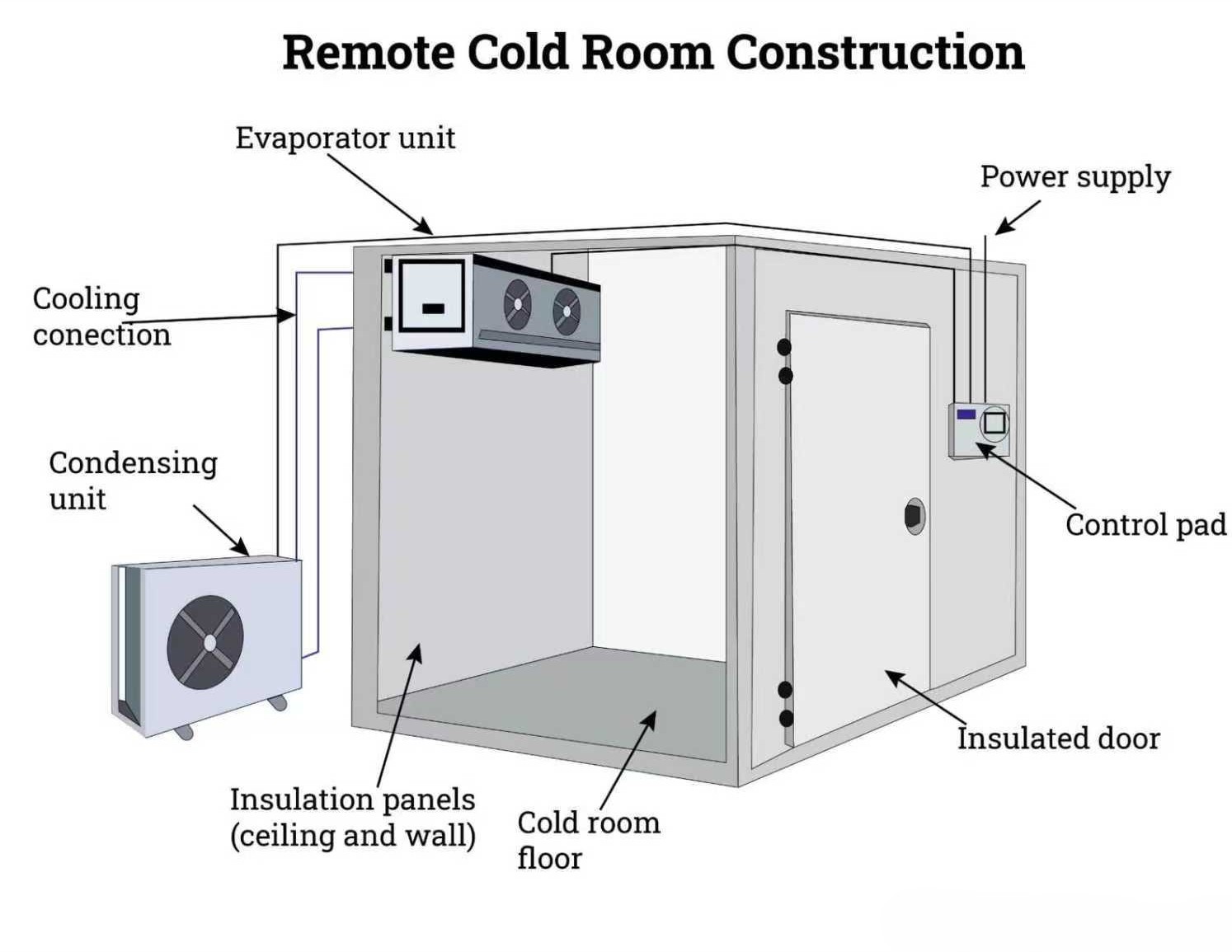

A cold storage chamber constitutes a specialised warehousing facility integrating high-efficiency thermal insulation structures with precision refrigeration technology. It employs high-density polyurethane sandwich panels to construct an airtight space that blocks external heat ingress, whilst utilising a mechanical refrigeration system (compressor, condenser, and evaporator) to continuously remove internal thermal loads. This creates and maintains a constant low-temperature environment (typically encompassing fresh-keeping or freezing temperature zones) and specific humidity conditions within the enclosed space. Its core purpose lies in employing physical cooling methods to inhibit microbial proliferation, reduce enzymatic activity, or slow biochemical reaction rates. This maximises the shelf life and economic value of heat-sensitive products such as foodstuffs, pharmaceuticals, and chemical raw materials, serving as critical infrastructure within modern cold chain logistics systems to safeguard product quality.

Core characteristics of Cold Room

Structure of the storage facility and high-efficiency insulation

Polyurethane (PU) Sandwich Panels:

High-density Foaming: Premium cold storage panels employ high-pressure foaming technology, typically achieving densities between 40–42 kg/m³. This density ensures exceptionally low thermal conductivity, minimising cold loss to the greatest extent.

Fire Rating: Modern panels typically meet Class B1 (difficult to ignite) or Class B2 (combustible but flame-retardant treated) fire standards, complying with stringent building fire codes.

Panel Material Diversity: Surface materials vary by application: colour-coated steel (standard), 304 stainless steel (food/pharmaceutical grade), embossed aluminium (anti-slip flooring), or galvanised steel (corrosion-resistant).

Professional access control and sealing systems

Cold storage doors are the most frequent points of cold air loss and therefore feature specialised design elements.

Anti-freeze heating elements: Electric heating wires are embedded around the door frame in low-temperature cold stores (below -18°C) to prevent the door seal from freezing and adhering to the frame, ensuring the door can be opened at any time.

Safety Release: All cold storage doors must incorporate an internal escape lock mechanism. Even if the door is locked from the outside, personnel inside can easily open it via a push bar or knob, preventing entrapment incidents.

Powerful and precise cooling system

Unit Configuration:

Monoblock: Compressor and evaporator integrated into a single unit for wall-mounted installation. Characterised by exceptionally straightforward installation requiring no copper pipework, suitable for small cold stores.

Split System: Compressor (outdoor) and evaporator (indoor) separated. Features low noise levels and superior heat dissipation, suitable for medium to large cold stores.

Compressor Technology:

Utilises scroll or semi-hermetic reciprocating compressors (e.g., Copeland, Bitzer), delivering high coefficient of performance (COP) and robust low-backpressure operation.

Intelligent Control and the Internet of Things

Modern refrigeration units no longer rely on simple thermostats but incorporate intelligent management features.

Microprocessor-controlled precision temperature regulation:

Utilising high-precision sensors, temperature control accuracy reaches ±0.1°C. The control system automatically adjusts compressor start/stop cycles or variable-frequency operation to maintain constant temperatures.

· PrFood processing workshops

· Cold stores and freezer rooms

· Cold chain logistics centres and distribution warehouses

· Pharmaceutical factories and cleanrooms

· Biological laboratories and sample repositories

· Flower preservation chambers

· Low-temperature storage for

| Product Type |

Portable Cold Storage Room |

|

Structure |

Assembled |

|

Usage |

Meat, Fish, Food, Fruit, Chicken, Vegetables |

|

Certification |

RoHS, ISO, CE |

|

Condition |

New |

|

Cold Room Panels |

PU Foam Core Sandwich Panel/PlR (Polyisocyanurate)Foam Core Sandwich Panel |

|

Surface Treatment |

Color Steel/Stainless Steel/Stucco Embossed Aluminum |

|

Floor |

PU Panel / Concrete with XPS / Checker Plate |

|

Refrigeration System |

New Generation Smart Cooling System |

|

Compressor |

Bitzer |

|

Evaporator |

Air Cooled (Ceiling Mounted, Floor Mounted) |

|

Energy Effciency |

Grade l |

|

Service Door |

Customized |

|

Product Name |

Movable Portable Cold Room for Food and Drug Trans |

|

Specification |

Customized |

Comprehensive FAQ: Cold Storage Rooms & Walk-in Freezers

Part 1: General Definitions & Types

1. What is the difference between a Cold Storage Room (Chiller) and a Freezer Room?

While both look structurally similar, the key difference lies in temperature range and application:

-

Chiller Room (Medium Temperature): Operates between 0°C and +5°C (32°F - 41°F). It is designed to preserve fresh products like vegetables, fruits, dairy, and beverages without freezing them. The goal is to slow down bacterial growth and enzymatic activity.

-

Freezer Room (Low Temperature): Operates between -18°C and -25°C (0°F - -13°F). It is designed to keep products frozen solid (meat, fish, ice cream). The refrigeration system requires more power, thicker insulation, and specific defrosting mechanisms compared to a chiller.

2. What is a "Blast Freezer" and how does it differ from a standard freezer?

A standard freezer is designed for holding already-frozen goods. A Blast Freezer (or Shock Freezer) is designed for processing.

-

Function: It uses high-velocity fans and powerful compressors to pull the temperature of fresh food down to -18°C core temperature extremely fast (usually within 4 to 6 hours).

-

Why use it? Rapid freezing creates "micro-crystals" inside the food cells. Slow freezing creates large jagged ice crystals that puncture cell walls, causing "drip loss" and mushy texture upon thawing. Blast freezing preserves the quality, texture, and nutritional value of the food.

3. What is a "CA" (Controlled Atmosphere) Cold Store?

A Controlled Atmosphere (CA) store is an advanced cold room typically used for long-term fruit storage (like apples, pears, or kiwis).

-

Mechanism: In addition to controlling temperature, a CA room tightly controls the gas composition of the air. It reduces Oxygen (O2) and increases Carbon Dioxide (CO2) and Nitrogen.

-

Benefit: This puts the fruit into a state of "hibernation," slowing down its respiration rate. This allows seasonal fruits to be stored for 6 to 9 months and sold year-round as if they were fresh.

4. Can I use a standard air conditioner (AC) to cool a small cold room?

No. This is a common mistake that leads to equipment failure.

-

Design Difference: Standard AC units are designed to cool air to roughly 18°C-22°C. They are not designed to handle the moisture load or the low temperatures of a cold room (0°C).

-

The Result: If you force an AC to run at 5°C, the evaporator coil will freeze up immediately because it lacks a defrost mechanism. Furthermore, the compressor is not designed for the pressure ratios required for refrigeration, leading to premature burnout.

Part 2: Structure & Insulation

5. Why are Polyurethane (PU) panels the industry standard for cold rooms?

Polyurethane is used because it offers the best strength-to-insulation ratio.

-

Thermal Efficiency: PU has an extremely low thermal conductivity (K-value roughly 0.022 W/mK), meaning it keeps heat out very effectively.

-

Structural Integrity: When "sandwiched" between steel sheets, high-density PU foam (40-42 kg/m³) becomes rigid enough to support the ceiling and walls without needing an external skeleton for small to medium rooms.

-

Hygiene: PU panels are moisture-resistant and do not rot or harbor mold, which is critical for food safety standards (HACCP).

6. How do I determine the correct panel thickness?

Thickness depends on the temperature difference between the inside of the room and the outside ambient air. General guidelines are:

-

Chiller Rooms (0°C to +5°C): Typically use 75mm or 100mm thick panels.

-

Freezer Rooms (-18°C to -25°C): Typically use 120mm or 150mm thick panels.

-

Blast Freezers (-40°C): Require 150mm or 200mm panels.Using panels that are too thin causes condensation on the outside walls ("sweating") and forces the compressor to run continuously, wasting electricity.

7. What is the "Cam-Lock" system and why is it important?

Cam-locks are eccentric hook mechanisms embedded inside the foam of the panels.

-

Assembly: During installation, an Allen key is used to turn the lock, pulling the male and female edges of two panels tightly together.

-

Importance: This creates a tight mechanical seal without relying solely on glue or screws. It prevents "thermal bridges" (gaps where heat enters) and allows the cold room to be disassembled and moved to a new location in the future, which makes the asset modular and reusable.

8. Does a cold room need a special floor?

-

Chiller Rooms: Often use the existing concrete floor if it is level, though an insulated floor is better for efficiency.

-

Freezer Rooms: Must have an insulated floor. If you build a freezer directly on concrete without insulation, the cold will penetrate downward, freezing the moisture in the soil below. This causes the ground to expand and heave (Frost Heave), which can crack the building's foundation and destroy the freezer floor.

-

Finish: The top surface usually uses checkered aluminum plates (anti-slip) or stainless steel for hygiene.

Part 3: Refrigeration System & Components

9. What is the difference between Monoblock and Split refrigeration units?

-

Monoblock (All-in-One): The compressor, condenser, and evaporator are built into a single compact unit that hangs through a hole in the wall.

-

Pros: Easiest to install (plug and play), no piping work needed.

-

Cons: Hot air is vented into the surrounding room (unless ducted), and they are generally limited to smaller capacities.

-

-

Split System: The condensing unit (noisy part) is placed outdoors, and the evaporator (cooling fan) is inside the room. Connected by copper piping.

-

Pros: Keeps noise and heat outside; supports much larger capacities and longer pipe runs.

-

Cons: Requires a certified technician to weld pipes and charge refrigerant.

-

10. How does the defrost system work, and why is it necessary?

Moisture in the air freezes onto the cold evaporator coils, forming ice. If this ice builds up, it blocks airflow, and the room gets warm.

-

Electric Defrost: Heater elements (like in a toaster) are embedded in the coil. The system pauses cooling, turns on heaters to melt the ice, and drains the water away. Common in freezers.

-

Air Defrost: In chiller rooms (above 2°C), the compressor stops, but the fans keep running. The room air melts the frost naturally.

-

Hot Gas Defrost: Hot refrigerant gas from the compressor is diverted backward through the evaporator. This is the fastest and most energy-efficient method but requires complex valving.

11. Why do cold storage doors have heater wires?

In freezer rooms, the temperature difference creates condensation around the door frame. This moisture can freeze, effectively welding the door shut.

-

Solution: A resistance heater wire is embedded in the door frame (or the door gasket). It keeps the perimeter just warm enough to prevent condensation and ice formation, ensuring the door can always be opened easily and the rubber seal doesn't tear.

12. What is a Pressure Relief Port (or Decompression Valve)?

When a freezer door is opened, warm air rushes in. When the door closes, that air cools down rapidly and shrinks (contracts).

-

The Physics: This contraction creates a vacuum inside the room. Without a relief port, the negative pressure can be so strong that you physically cannot pull the door open, or it might even collapse the ceiling panels inward.

-

The Valve: A small heated vent in the wall that equalizes the pressure automatically, allowing the door to open freely.

13. Which refrigerants are currently recommended given environmental regulations?

Old refrigerants like R22 are banned in most places.

-

Current Standard: R404A has been the standard for years but has a high Global Warming Potential (GWP) and is being phased out in Europe and parts of the US.

-

Modern Alternatives: R448A and R449A are popular, non-flammable replacements with lower GWP.

-

Future Proof: CO2 (R744) is becoming the standard for large industrial cold stores. It is natural, highly efficient, and future-proof against regulation, though the equipment is more expensive initially.

Part 4: Usage & Maintenance

14. How should I stack products inside the cold room?

Proper airflow is critical. The cold air must circulate around the products to remove heat.

-

The Rule: Never block the evaporator fans. Leave at least 30-50cm of clearance in front of the fans.

-

Pallets: Keep products on pallets or shelving, not directly on the floor.

-

Walls: Leave a 5-10cm gap between the product and the wall panels to allow air to "envelope" the cargo.

15. What is an "Air Curtain" and is it worth the cost?

An air curtain is a fan unit mounted above the door that shoots a high-velocity stream of air downward when the door opens.

-

Function: It creates an invisible barrier that prevents cold air from falling out and warm air/insects from flying in.

-

Worth it? Yes. If the door is opened frequently, an air curtain can pay for itself in energy savings within 1-2 years by reducing the load on the compressor.

16. Why is there ice building up on the floor or ceiling?

-

Ceiling Ice: Usually indicates an air leak in the roof panel joints or a lack of vapor barrier, allowing humid air to penetrate and freeze.

-

Floor Ice: Often caused by a damaged door seal (warm air enters at the bottom), or a blocked drain line. If the evaporator drain line heater fails, the water from the defrost cycle spills onto the floor and freezes.

17. How often should the cold room be serviced?

-

Quarterly (Every 3 months): Clean the condenser coils (outdoor unit) to ensure heat rejection. Check door seals for tears.

-

Semi-Annually: Check refrigerant levels (sight glass), oil levels, and electrical connections.

-

Annually: Thorough inspection of the evaporator fans, drain heaters, and calibration of the temperature sensors.

Part 5: Design & Energy Efficiency

18. What is "Pull-Down Time"?

Pull-down time is the duration required to lower the temperature of the products from their incoming temperature to the storage temperature.

-

Calculation: When sizing a unit, you must tell the engineer the "daily product turnover." Putting 10 tons of warm apples into a room requires a much larger compressor than holding 10 tons of already-cold apples.

-

Standard: A standard holding room is usually designed to handle a 10% daily product turnover with a pull-down time of 18-24 hours.

19. How can I reduce the electricity bill for my cold storage?

-

Door Management: This is the #1 energy loss. Install automatic door closers or strip curtains (PVC strips).

-

LED Lighting: Use LED lights specifically designed for cold rooms. Old incandescent bulbs add heat to the room, which the compressor then has to remove.

-

Night Blind/Covers: If open display cabinets are used inside, cover them at night.

-

Smart Defrost: Upgrade to a controller that defrosts "on demand" rather than on a fixed timer.

20. Can I monitor the cold room remotely?

Yes, this is highly recommended for food safety compliance.

-

IoT Solutions: Modern controllers (like Dixell XWEB or Carel Boss) connect to the internet.

-

Alerts: You can receive SMS or email alerts if the temperature rises above a set limit ("High Temp Alarm"), if the door is left open, or if the power goes out. This allows you to save the inventory before it spoils.