Cold storage door control system

this system Designed for reliability and ease of installation, converts manual sliding doors into fully automatic access points. It is the perfect balance of performance and cost-efficiency for mid-sized cold rooms and warehouses.

Intelligent Controller:

Frequency Conversion Control: The integrated inverter allows for variable speeds—fast opening to clear traffic, and controlled closing to ensure a tight seal.

Digital Display & Diagnostics: The external LED screen displays current status and error codes, making troubleshooting instant and effortless.

Interlock Capability: Can be interlocked with air curtains or other doors to create a perfect airlock system.

Remote App Control (Optional): Monitor door status and cycle counts via a mobile app integration.

Soft Motion Technology

Features soft start and soft stop functions to reduce mechanical stress on the door frame and extend service life.

Automatic Safety Reverse

If the door encounters an obstacle (person or forklift) during closing, it automatically reverses to prevent injury.

Versatile Operation

Supports remote control, push-button, and pull-rope switches.

· PrFood processing workshops

· Cold stores and freezer rooms

· Cold chain logistics centres and distribution warehouses

· Pharmaceutical factories and cleanrooms

· Biological laboratories and sample repositories

· Flower preservation chambers

· Low-temperature storage for

|

Product Type |

Cold storage door control system |

||

| Power Supply |

AC 220V/50Hz 110V/50Hz(Customizable) |

||

| Motor Power |

250W / 400W Brushless DC |

||

| Door Weight Capacity |

Up to 800kg |

||

| Operating Temp | -25°C to +45°C | ||

| Opening Speed | 25-40 cm/s (Adjustable) | ||

| Protection Class | IP55 (Dust & Water Resistant) | ||

| Control Type |

PLC + Frequency Inverter |

||

| Motor Type |

Servo Motor / High-Torque AC |

||

| Activation Options |

|

||

| Safety System |

Infrared Photocell + Safety Edge |

||

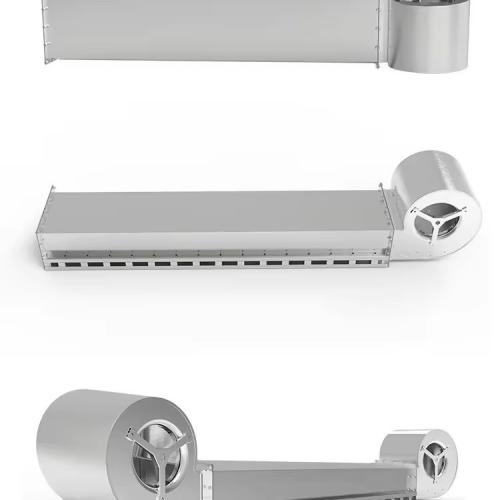

| Heating Element |

Integrated Control Box Heater |

FAQ

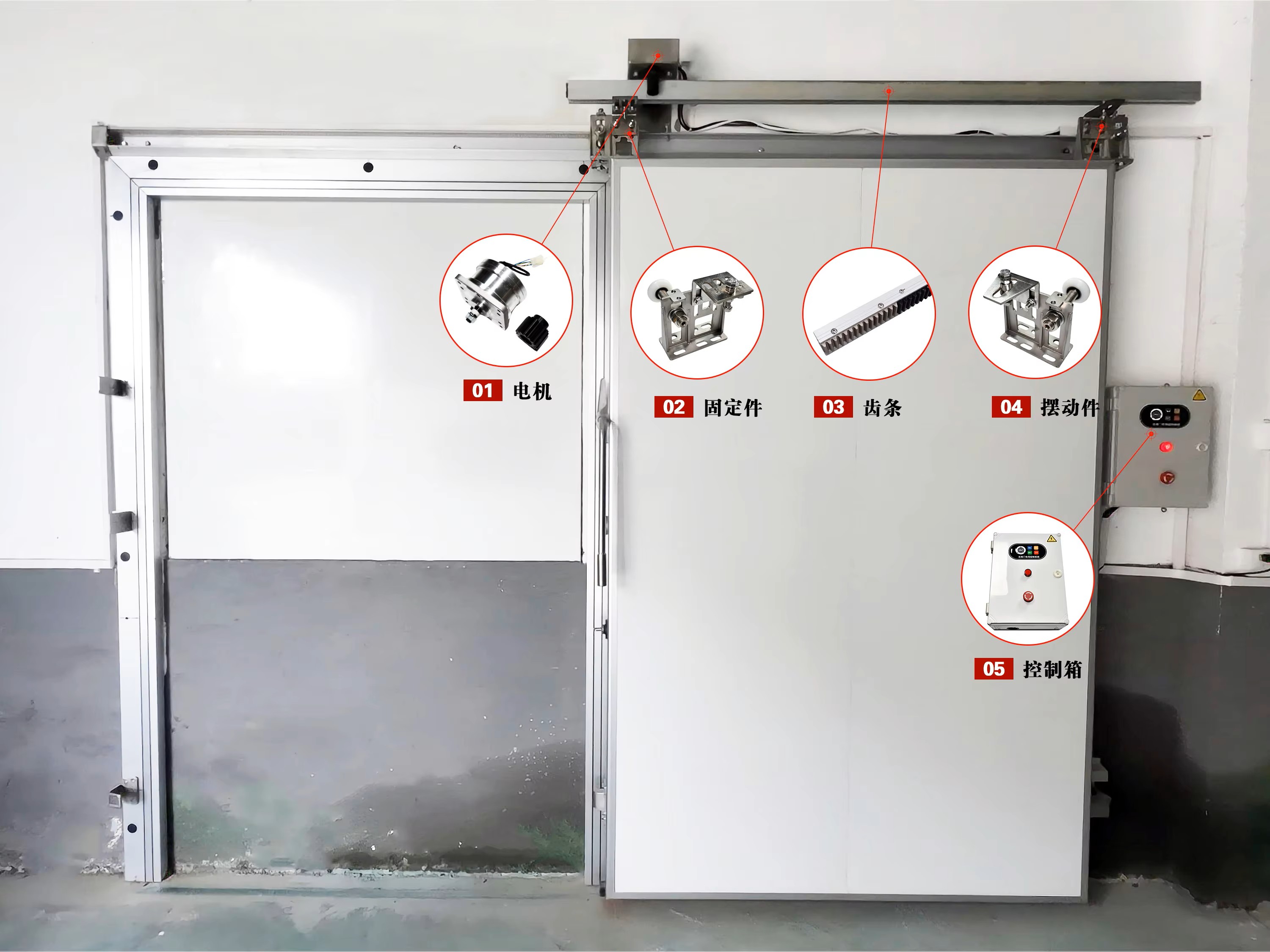

1. What is a cold storage sliding door electric control system?

It is an automation kit designed to convert manual cold storage sliding doors into automatic ones. It typically consists of a motor, a control box (PLC/Inverter), a drive track or belt, and various activation sensors.

2. Can your system be retrofitted onto existing manual doors?

Yes, our systems are designed to be universal. They can be installed on most existing manual sliding doors, provided the door track and wheels are in good condition.

3. What types of cold storage doors is this system compatible with?

It is compatible with light, medium, and heavy-duty horizontal sliding doors used in chillers, freezers, blast freezers, and controlled atmosphere rooms.

4. What is the difference between a standard motor and an inverter (VFD) system?

A standard motor operates at a fixed speed. An inverter (VFD) system allows for variable speeds (soft start and soft stop), which protects the door mechanics and allows for faster opening times to save energy.

5. Do you offer systems for stainless steel or food-grade environments?

Yes, we offer motor kits with IP65-rated stainless steel control boxes and corrosion-resistant components suitable for food processing and pharmaceutical applications.

6. What is the input voltage requirement?

Our standard units are single-phase 220V/50Hz. However, we can customize motors for 110V/60Hz or 3-phase 380V depending on industrial requirements.

7. What is the maximum door weight your motor can handle?

We have different models ranging from light-duty (up to 200kg) to heavy-industrial (up to 800kg or 1000kg).

8. What is the operating temperature range?

Standard models operate between -20°C to +45°C. For blast freezers, we offer a low-temperature series capable of operating down to -45°C with integrated heating elements.

9. What is the opening and closing speed?

Speeds typically range from 20cm/s to 50cm/s. Systems equipped with a frequency inverter can be adjusted to run faster (up to 60cm/s) to minimize air loss.

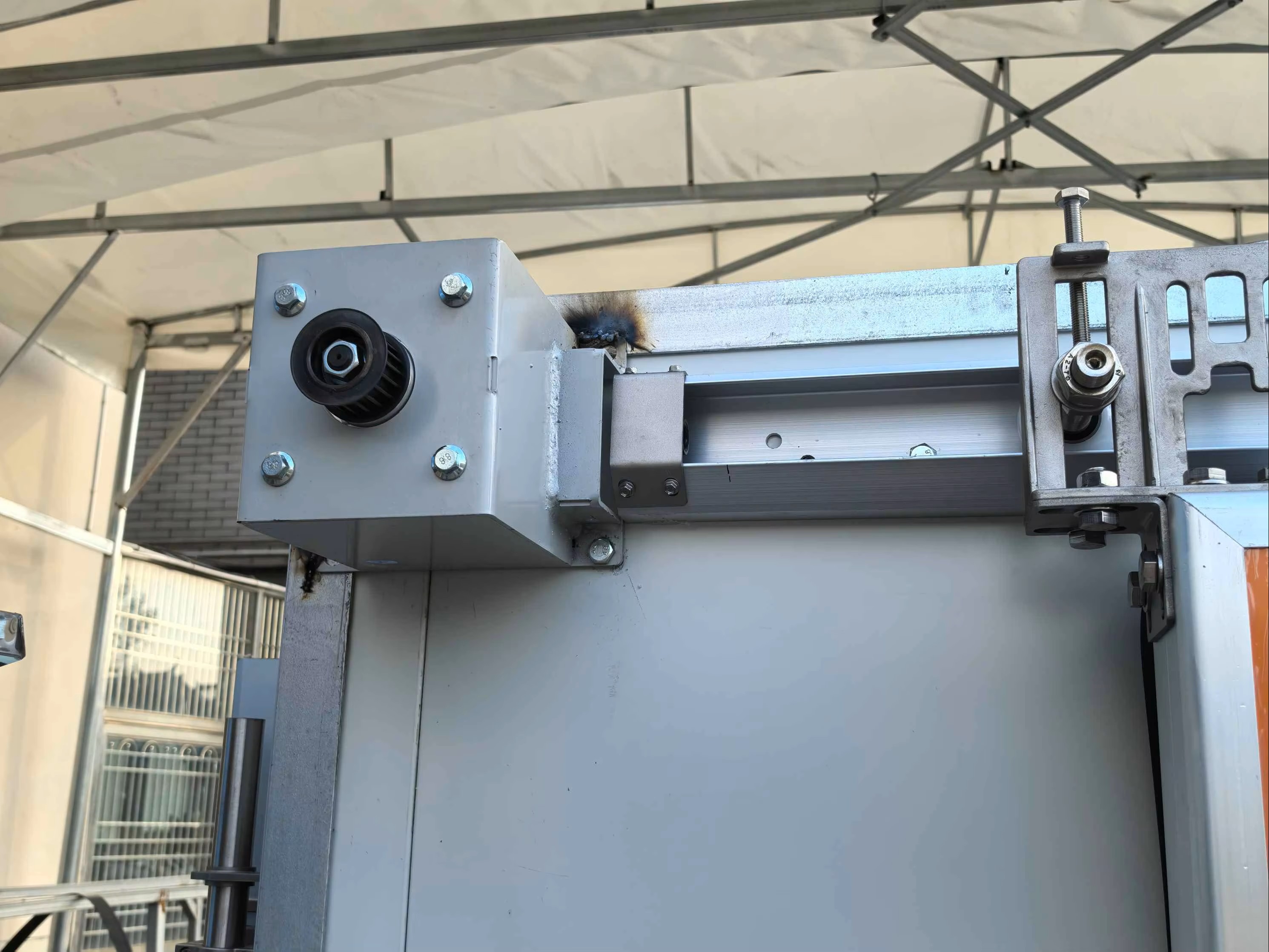

10. Does the motor use a belt drive or a rack and pinion?

We offer both. Rack and pinion is better for heavy, industrial doors, while synchronous belt drives are quieter and smoother for smaller to medium-sized doors.

11. What is the IP rating of the control box?

Our standard control boxes are rated IP54 or IP65, protecting against dust ingress and low-pressure water jets (wash-down safe).

12. Does the system support "Drop Down" (hermetic) rail systems?

Yes, our motors have a specialized "closing force" setting that pushes the door firmly at the end of the cycle to engage drop-down rails and ensure a hermetic seal.

13. Can I install the motor on either the left or right side?

Yes, the system is reversible. The opening direction (left or right) can be easily set via the DIP switches or the digital controller menu.

14. How much space is required above the door for installation?

Generally, you need at least 150mm to 200mm of clearance above the door track to mount the motor and drive mechanism.

15. Do you provide wiring diagrams?

Yes, every unit comes with a detailed English installation manual and wiring diagram. We also offer video support for technicians.

16. Is the limit switch mechanical or digital?

We use encoder-based digital limit setting for our advanced models (no physical limit switches to adjust). Economy models may use magnetic or mechanical limit switches.

17. What happens if the door hits an obstacle while closing?

The system features an automatic reverse function. If the motor detects resistance (like a forklift or person), it will stop and reverse to the open position immediately.

18. Does the system function during a power outage?

In the event of power failure, the electric clutch disengages (or can be manually disengaged), allowing the door to be opened and closed manually with very little effort.

19. Is there an "emergency stop" feature?

Yes, the control box usually includes a large Red Emergency Stop button. Additionally, safety edges can be installed on the door leaf.

20. Can I set an automatic closing timer?

Yes, you can program the door to automatically close after a set time (e.g., 10 seconds, 30 seconds) to prevent employees from leaving the freezer open accidentally.

21. What is the "Half-Open" or "Pedestrian" mode?

This feature allows the door to open only partially for personnel entry, minimizing cold air loss compared to fully opening for a forklift.

22. What types of switches can trigger the door?

The system supports push buttons, pull cords (ceiling switches), remote controls, radar sensors, magnetic induction loops, and facial recognition terminals.

23. Can I use a remote control?

Yes, most of our controllers have a built-in receiver module that supports wireless remote controls up to a range of 50-100 meters.

24. Can this system interface with an Air Curtain?

Yes, the control box has a relay output specifically for air curtains. It turns the air curtain on when the door opens and off when it closes.

25. Does it support Interlocking (Airlock) function?

Yes, for facilities with anterooms, two doors can be interlocked so that Door B cannot open until Door A is fully closed.

26. Do I need a safety edge sensor?

While the motor has built-in resistance detection, we highly recommend installing a rubber safety edge (air wave or electric) for maximum safety compliance.

27. How do I troubleshoot errors?

The advanced control box features an LED display that shows error codes (e.g., E1 for motor error, E2 for sensor blockage), making troubleshooting easy.

28. Does the motor require lubrication?

Most of our motors use sealed bearings and are maintenance-free. However, the drive chain or rack should be greased periodically, especially in humid environments.

29. Why is my door moving slowly?

This could be due to ice build-up on the track, worn-out roller wheels, or the speed setting on the inverter needs adjustment.

30. What happens if the door freezes shut?

Our motors have a high starting torque to break minor frost seals. For severe icing, we recommend installing frame heating cables to prevent the door from sticking.

31. What is the warranty period?

We typically offer a 12-month to 24-month warranty on the motor and control board, depending on the model purchased.

32. Do you sell spare parts separately?

Yes, we stock replacement control boards, remotes, belts, and motors for quick shipment.

33. Can you customize the logo on the control box?

Yes, we offer OEM services and can print your company logo on the control panel for bulk orders.

34. What is the lead time for 50 sets?

Standard production time is usually 10-15 days for orders under 100 sets.

35. How is the product packaged for export?

The kits are packed in reinforced carton boxes with foam padding. For larger shipments, we use wooden pallets to prevent damage during sea freight.