Heating Cables For Coolroom Pipes And Roofs

Blocked drain pipes can lead to water leakage and costly damage in your cold room. Our Drain Line Heater is specifically designed to fit inside or outside pipes to maintain a steady temperature above freezing. Completely waterproof and double-insulated, it provides a safe, set-and-forget solution to keep your drainage systems flowing freely.

Easy Installation

Cold Room Door Heater Cables are easy to install, minimizing down time and labor costs. Their flexible design allows them to easily conform to the door's shape and navigate around obstacles, reducing the need for complex routing or cutting. The cables come with self-adhesive strips and clips for securing them to the door to ensure proper placement. provides clear and detailed installation instructions, complete with diagrams and step-by-step guidance to guarantee correct and efficient installation. These Cold Room Door Heater Cables are designed to be compatible with most standard cold room doors to minimize the need for modifications or custom installations. With only basic tools such as a screwdriver and wire cutters required, the installation process is made simpler and more cost-effective.

Customizable

our Cold room door heater cables are designed to be tailored to the specific needs of your cold storage facilities. These cables can be cut to the exact length required for your door to minimize waste and ensure optimal performance.

Additionally, the voltage of the cables can be adjusted to match your facility's electrical system for compatibility and safety. The wattage of our cables can also be customized to provide the appropriate amount of heat for your specific door size and insulation requirements.

This high level of customization allows our cold room door heater cables to meet diverse industrial and commercial needs that provide flexible and efficient heating solutions for a wide range of applications.

Made with High-Grade Materials

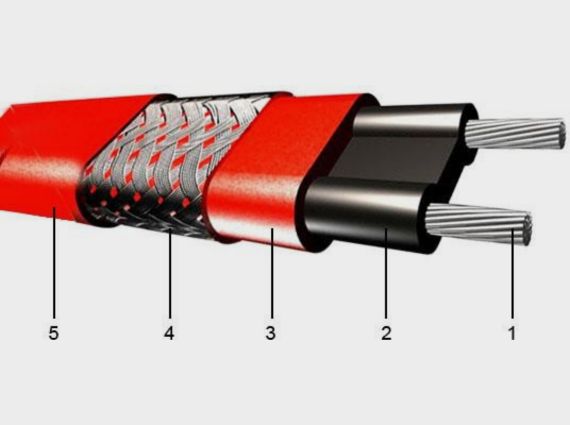

cold room door heater cables are made with high-quality materialsto ensure long-lasting, efficient, and safe performance.

These materials typically include a nickel-chrome alloy heating element, a fiberglass or mica core, silicone and Teflon insulation, and a PVC or FEP outer sheath. This design is meant to provide reliable functionality and durability over a long period of time.

· PrFood processing workshops

· Cold stores and freezer rooms

· Cold chain logistics centres and distribution warehouses

· Pharmaceutical factories and cleanrooms

· Biological laboratories and sample repositories

· Flower preservation chambers

· Low-temperature storage for

|

Product Name |

Silicone Rubber Heating Wire / Defrost Cable |

|||

| Conductor Material |

|

|||

| Insulation Material |

Silicone Rubber (Optional: Fiberglass Braid for extra protection) |

|||

| Voltage |

12V / 24V / 110V / 220V / 230V (Customizable) |

|||

| Power Output | Standard: 20W/m, 30W/m, 40W/m, 50W/m (Max: ~60W/m) | |||

| Temperature Range | -60°C to +200°C (-76°F to +392°F) | |||

| Wire Diameter | 2.5mm, 3.0mm, 4.0mm, or Flat Type | |||

| Waterproof Rating |

|

|||

| Cold Lead Length |

Standard 1000mm (or customized) |

|||

| Color |

|

|||

| Certifications |

CE, UL, RoHS, VDE |

|||

| Applications |

Defrosting refrigerators, cold rooms, drain pipes, door frames |

FAQ

-

What is a cold storage heating wire?

It is a flexible electrical heating element, typically insulated with silicone rubber, used to prevent ice buildup in cold environments like freezer door frames, drain pipes, and evaporator coils. -

What is the temperature range of your heating wire?

Our silicone heating wires are designed to operate effectively between -60°C and +200°C (-76°F to +392°F). -

What is the difference between Silicone and PVC heating wires?

Silicone is far superior for cold storage. It remains flexible and does not crack at sub-zero temperatures, whereas PVC can become brittle and break in extreme cold. -

Can I cut the heating wire to any length?

No. Most standard resistance heating wires have a fixed resistance per meter. Cutting them shortens the circuit, increases the current, and will cause the wire to burn out instantly. (Note: Only parallel constant wattage or self-regulating cables can be cut). -

What is the standard power output (Wattage)?

Common power densities range from 20W/m to 50W/m. 40W/m is the industry standard for drain pipes and door frames. -

Do you offer different voltages?

Yes. We can customize the voltage to 12V, 24V, 110V, 220V, or 380V depending on your power supply requirements. -

What is the diameter of the wire?

Standard diameters are roughly 2.5mm to 4.0mm. We also offer flat (ribbon) profiles for specific door seals. -

Does the wire come with a "cold tail" (non-heating lead)?

Yes. To ensure safety, the connection point usually includes a non-heating lead wire (cold tail) of 1 meter (or custom length) for connecting to the power source. -

Is the heating wire waterproof?

Yes, our silicone heating wires are rated IP67, meaning they are fully waterproof and can be submerged in water (ideal for drain pipes). -

What material is used for the conductor?

We use high-quality Nickel-Chromium (NiCr) or Copper-Nickel alloy for stable resistance and long service life.

-

Where should I install this heating wire?

Common spots include:-

Inside the drain pipe of a cold room air cooler.

-

Around the door frame of a walk-in freezer.

-

On the drip tray of the evaporator.

-

Around compressor crankcases.

-

-

How do I attach the wire to a pipe?

We recommend using Aluminum Foil Tape. This secures the wire and helps spread the heat evenly across the pipe surface. -

Can I overlap the heating wire during installation?

Absolutely NOT. Overlapping the wire causes "hot spots" which will melt the insulation and cause failure or fire. The wire must always be spiraled or run straight without touching itself. -

Do I need a thermostat or temperature controller?

It is highly recommended. While some low-wattage wires can run continuously, using a thermostat saves energy and extends the life of the wire by turning it off when not needed. -

How do I install it inside a drain line?

Simply insert the wire into the pipe. The end of the wire must be sealed (waterproof cap). Ensure the heating part extends fully through the cold zone to the outside. -

Can this wire be used for floor heating in a cold room?

Standard door heater wire is too thin for floors. For floor frost heave protection, we recommend our heavier-duty armored heating cables or mating systems. -

Does the wire stay flexible in freezing conditions?

Yes, the silicone rubber insulation ensures the wire remains soft and pliable even at -50°C, making maintenance easy. -

What if the wire is too long for my pipe?

Do not cut it. You should spiral it slightly closer together (without overlapping) or let the excess hang outside the pipe in a safe area.

-

Is your heating wire safe for food storage environments?

Yes, silicone rubber is inert and odorless. It does not release harmful chemicals, making it safe for food cold chains. -

What certifications do your products have?

Our products are manufactured according to CE, UL, and RoHS standards. -

How do you prevent the connection joint from failing?

We use high-pressure molding to bond the heating wire and the cold lead. This creates a completely waterproof, integrated seal that resists moisture ingress. -

What happens if the wire gets damaged?

If the insulation is cut or the wire is broken, it must be replaced immediately to prevent short circuits or electric shocks. -

Is there a risk of fire?

Only if installed incorrectly (e.g., overlapping or wrong voltage). When installed correctly with a fuse and thermostat, they are extremely safe. -

How long is the lifespan of the wire?

Under normal usage conditions, high-quality silicone heating wires can last for 5 to 10 years. -

Can it withstand chemical cleaning agents?

Silicone is resistant to most mild cleaning agents, but harsh acids or solvents should be avoided.

-

What is the Minimum Order Quantity (MOQ)?

Our standard MOQ is usually 100 pieces per specification, but we accept smaller trial orders for testing. -

Can you print my brand logo on the wire?

Yes, we offer OEM services. We can print your logo, voltage, and wattage specifications directly on the insulation or the packaging label. -

What information do I need to provide for a quote?

Please provide:-

Voltage (e.g., 220V)

-

Total Power or Power per meter (e.g., 40W/m)

-

Total Length (heating length + cold tail length)

-

Application (Door or Drain?)

-

-

What is your standard lead time?

For standard orders, production takes 7-14 days. Custom orders may take slightly longer. -

How is the product packaged?

Usually in individual PE bags, then packed in master cartons. We can also provide custom retail boxes with barcodes. -

Can I get a free sample?

Yes, we provide free samples for stock items. You only need to cover the shipping cost. -

Do you ship internationally?

Yes, we export globally via sea (LCL/FCL), air cargo, or express couriers (DHL/FedEx/UPS). -

What payment terms do you accept?

We accept T/T (Bank Transfer), L/C, PayPal (for samples), and Western Union. -

Can you customize the plug?

Yes, we can attach standard plugs (EU, US, UK, AU) to the cold tail upon request.