Industrial PVC Cold room swing door

Description of Industrial PVC Cold room swing door

This PVC Cold Storage swing door delivers reliable sealing and outstanding thermal efficiency for cold rooms and refrigerated warehouses. Constructed with durable, frost-resistant PVC panels, it minimizes temperature loss and reduces energy consumption. The smooth swing operation, sturdy hinges, and tight closing design ensure long-term performance under frequent use. It is widely applied in food storage, logistics centers, and commercial refrigeration applications.

Core characteristics of Industrial PVC Cold room swing door

Material & Low‑Temperature Performance

Flexible, cold‑resistant PVC panels (typically 5–12 mm thick) remain pliable down to −25 °C without cracking or hardening.

Food‑grade compliance: Meets EU 1935/2004 and 10/2011 for direct food contact.

Impact‑resistant: Soft PVC deforms under forklift/cart impact and quickly rebounds.

Hygienic: Smooth, non‑porous surface is easy to clean and sanitize.

Thermal Insulation & Sealing

High thermal resistance: Minimizes heat exchange and cold loss, lowering energy use.

Tight perimeter seals: Prevents air infiltration and frost buildup.

Optional insulated cores (foam‑filled) boost R‑value for freezer rooms.

Operational Design

180° bidirectional swing with automatic closing via torsion‑spring hinges.

90° hold‑open option for bulk loading.

Light operation: Easy manual push; no heavy motors required.

Fast reset: Quiet, controlled closure to reduce traffic delays.

Structural & Hardware

Rigid frames: Galvanized steel, stainless steel (304), or aluminum for corrosion resistance.

Stainless steel hardware (hinges, brackets) for wet/cold conditions.

Reinforced bottom bumpers to withstand repeated impact.

Food Service: Restaurants, Cafeterias, Commercial Kitchens.

Retail: Supermarkets, Convenience Stores, Florists.

Industrial: Cold Storage Warehouses, Meat Processing Plants, Pharmaceutical Storage.

Medical: Vaccine Storage, Laboratory Cold Rooms.

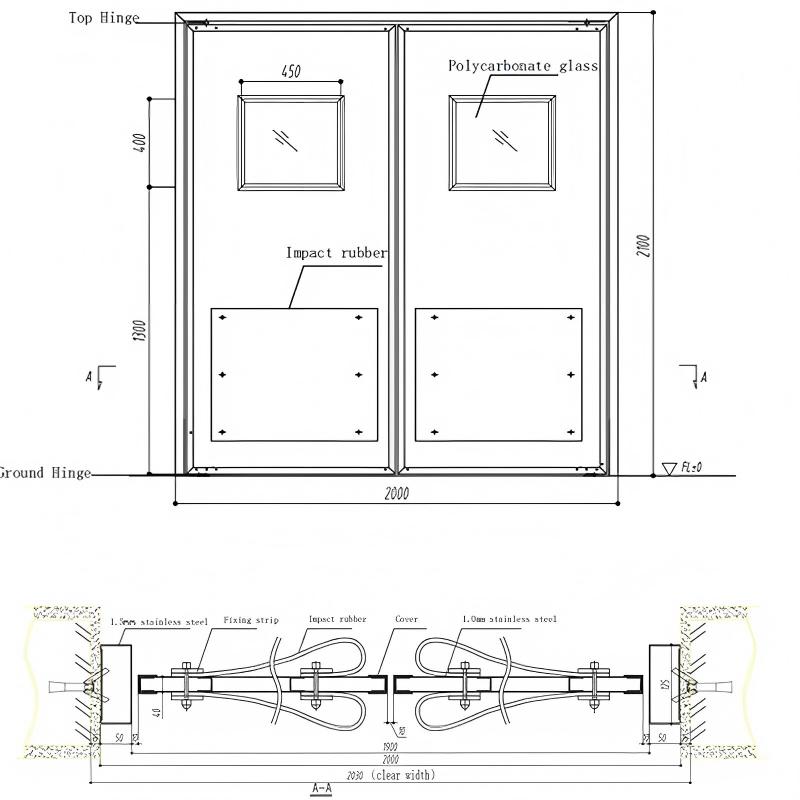

| Product Type |

Industrial PVC Cold room swing door |

|

Door

Thickness |

Standard

40mm (1.57") / Heavy Duty 50mm (2") options available |

|

Surface

Material |

High-impact

Polyethylene (PE) / 304 Stainless Steel / ABS |

|

Insulation

Core |

High-density

injected Polyurethane (PU) foam (CFC-Free) |

|

Impact

Resistance |

Designed

for Hand Truck, Pallet Jack, and Forklift traffic |

|

Hinge

System |

Stainless

Steel V-Cam Gravity Hinges (180° swing) |

|

Window

/ Vision Panel |

Double-glazed

Polycarbonate or Acrylic with rubber molding (Standard size: 300x400mm) |

|

Gasket

/ Seals |

EPDM

rubber perimeter seals (Replaceable), Oil and Low-temp resistant |

|

Temperature Range |

-40°C to +50°C (-40°F to 122°F) |

|

Bumper

Strips |

Optional:

bumpers or flat impact plates (Heights: 300mm to 1000mm) |

|

Frame

Compatibility |

Mounts

to C-Channel Steel, Stainless Steel, or Wood jambs |

|

Operation |

Dual-acting

(swings in both directions), Self-closing |

|

Cleaning |

Washdown

compatible, resistant to mild acids and alkalis |

FAQ

1. What is a cold storage swing door (often called a "free door")?

A cold storage swing door is a double-acting door designed for high-traffic areas. It can open 180 degrees (in both directions) and closes automatically using gravity hinges. It is designed to separate different temperature zones while allowing people and forklifts to pass through quickly.

2. What are the other names for a cold storage swing door?

In the industry, these are also known as Traffic Doors, Impact Doors, Crash Doors, Double Acting Doors, or Service Doors.

3. What is the main difference between a swing door and a sliding cold room door?

A sliding door provides a tighter thermal seal and is meant for storage rooms that are not opened frequently. A swing (traffic) door is designed for processing areas or loading docks with high frequency of entry/exit, prioritizing speed and workflow efficiency over a hermetic seal.

4. Can forklifts drive directly through these doors?

Yes, provided the door is equipped with protective bumpers (kick plates). The doors are designed to absorb impact and swing open when pushed by a forklift or pallet jack.

5. Are cold storage swing doors suitable for deep freeze (-20°C) applications?

Generally, swing doors are best for chillers (0°C to 10°C), food processing rooms, and loading docks. For deep freezers, we recommend a heavy-duty sliding door with heater wires to prevent freezing shut, although some insulated traffic doors can be used in mild freezer applications.

6. Do these doors help with energy saving?

Yes. By closing automatically and immediately after a person passes through, they minimize the infiltration of warm air and humidity, significantly reducing the load on your refrigeration system compared to keeping a door propped open.

7. Are your doors compliant with food safety standards (HACCP/GMP)?

Yes. Our doors are designed with smooth surfaces, no visible screws (where bacteria can hide), and food-grade materials like #304 Stainless Steel, making them easy to clean and compliant with international food hygiene standards.

8. What is the standard thickness of the door panel?

Our standard impact traffic doors typically feature a panel thickness of 40mm, which provides a good balance between insulation and lightweight operation.

9. What insulation material is used inside the door?

We use high-density Polyurethane (PU) foam injected under high pressure. This provides excellent thermal insulation and structural strength.

10. What material is the door surface made of?

Customers can choose between 304 Stainless Steel (best for hygiene and durability) or Painted Galvanized Steel (cost-effective). We also offer ABS or PE facing for specific impact requirements.

11. How does the "Gravity Hinge" system work?

Unlike spring hinges that can wear out, a Gravity Hinge uses the weight of the door to close it. When the door is pushed open, it rises slightly; gravity then pulls it back to the closed center position. This system is extremely durable and virtually maintenance-free.

12. Can the door stay open if needed (Hold-Open feature)?

Yes. The hinge design allows the door to "dwell" or stay open when pushed past 90 degrees. This is useful during sustained loading periods.

13. Are the windows on the door shatterproof?

Yes. We use double-glazed acrylic or polycarbonate windows. They are designed to be shatter-resistant for safety in busy industrial environments.

14. What are the "Bumpers" or "Kick Plates" made of?

We use high-impact PE (Polyethylene) or PVC sheets. These are installed on the lower half of the door to protect the stainless steel panel from scratches and dents caused by carts and forklifts.

15. What type of seal is used around the door edges?

We use high-quality, tear-resistant rubber gaskets along the vertical edges to prevent air leakage. These gaskets are easily replaceable.

16. Can these doors be installed on sandwich panel walls?

Yes, but the wall opening requires reinforcement. We recommend installing a C-channel sub-frame (aluminum or steel) inside the panel opening to support the weight and movement of the door.

17. Do you offer single-leaf and double-leaf options?

Yes. For narrow openings (under 1.2m wide), we recommend a Single Leaf door. For wider openings (up to 2.4m or more), a Double Leaf door is required.

18. Can I customize the size of the window?

Yes, while we have standard window sizes, we can customize the vision panel size or shape based on your specific requirements.

19. How do I measure the opening for a swing door?

We need the Clean Opening Width and Clean Opening Height (finish-to-finish dimensions). If you have a sub-frame installed, please measure the inside of the frame.

20. Is the installation process difficult?

No, it is relatively straightforward. The door frame is mounted to the wall, and the door leaves drop onto the hinge pins. Detailed installation manuals and video guides are provided with every order.

21. How long is the warranty period?

We provide a standard 1-year warranty on the door panel and hardware against manufacturing defects.

22. Do the hinges require lubrication?

Our gravity hinges are designed to be self-lubricating or use nylon bearings, requiring very little maintenance. However, applying a food-safe grease once a year ensures smooth operation.

23. Are spare parts (gaskets, hinges) easily available?

Yes. We stock all necessary spare parts. Since gaskets are wear-and-tear items, we can include extra sets in your initial shipment upon request.

24. What happens if the door gets scratched?

If you choose the Stainless Steel finish, minor scratches can be buffed out. For deep impacts, the bumper plates are designed to take the hit, preserving the structural integrity of the door.

25. How do you package the doors for export to prevent damage?

We use a triple-layer protection method: PE film wrapping + foam corner guards + fumigation-free plywood cases. This ensures the doors arrive scratch-free.

26. What is the Minimum Order Quantity (MOQ)?

Our MOQ is 1 set. We are happy to support both small sample orders and large project bulk orders.

27. What is the production lead time?

For standard sizes, production takes 7-10 days. For custom sizes or large quantities, it typically takes 15-20 days.

28. Can you print our company logo on the packaging?

Yes, we offer OEM services. We can label the packaging with your brand name, logo, and project reference numbers.