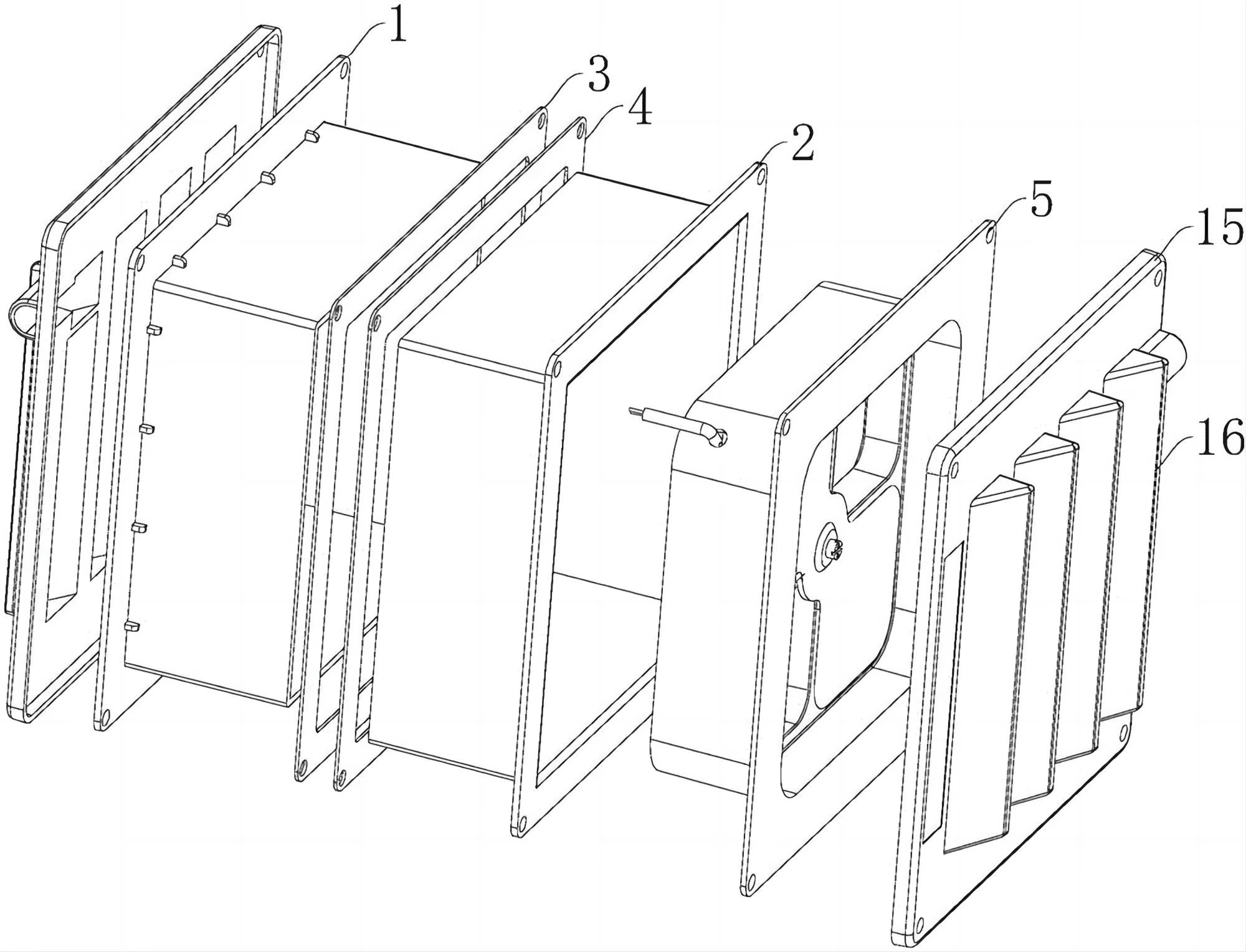

Square Pressure Relief Window

this is a high-capacity pressure relief valve (decompression port) designed specifically for industrial cold storage, walk-in freezers, and blast freezing applications. It features a thermostatically controlled heating element to ensure the valve shutters remain frost-free and operational in extreme low-temperature environments.

Short Description

Designed for environments where hygiene is non-negotiable. The InoxGuard valve combines pressure safety with sanitary design standards.

Key Benefits

Corrosion Resistant: Full 304 Stainless Steel construction resists harsh cleaning agents.

Sanitary Design: Smooth surfaces prevent bacterial harbor.

FDA Compliant: Materials meet food safety regulations for direct contact areas.

Best For

Meat processing plants, vaccine storage, seafood processing.

· PrFood processing workshops

· Cold stores and freezer rooms

· Cold chain logistics centres and distribution warehouses

· Pharmaceutical factories and cleanrooms

· Biological laboratories and sample repositories

· Flower preservation chambers

· Low-temperature storage for

|

Housing Material |

High-Impact ABS (UV Resistant) |

||

| Internal Flaps |

Lightweight Polycarbonate with Silicone Seals |

||

| Color |

Industrial Grey (RAL 7035) or White |

||

| Ingress Protection |

IP45 (External Face) |

||

| Fire Rating | UL94 V-0 (Self-extinguishing) | ||

| Mounting Orientation | Vertical (Wall) or Horizontal (Ceiling - requires adapter) | ||

| Net Weight | 1.2 kg | ||

| Input Voltage |

220V - 240V AC (Standard) / 110V AC (Optional) |

||

| Frequency |

50/60 Hz |

||

| Power Consumption |

|

||

| Heating Element Type |

Self-regulating PTC |

||

| Connection |

3-Core Cable (Live, Neutral, Earth), 1.5m Length |

FAQ

1. What is a cold storage pressure relief valve?

A pressure relief valve (also called a pressure equalization port or breather valve) is a safety device installed in walk-in freezers and cold stores. It allows air to flow in or out of the room to balance the internal pressure with the external atmospheric pressure.

2. Why do I need a pressure relief valve for my cold room?

When air inside a cold room cools down, it contracts, creating a vacuum (negative pressure). This can make the door impossible to open or, in severe cases, cause the walls and ceiling to collapse inward. Conversely, when the door opens or the defrost cycle runs, pressure increases. The valve prevents these structural dangers.

3. Do I need a relief valve for a chiller (cooler) or just a freezer?

While critical for freezers (operating below 0°C), they are also recommended for large airtight walk-in coolers. Although the pressure difference is less severe in coolers, a valve ensures the door opens smoothly and prevents stress on panel joints.

4. How does the valve work?

The valve contains mechanical flaps or dampers. When the pressure difference reaches a specific threshold (usually very low, around 10-20 Pascals), the flaps open to let air in or out. Once pressure is equalized, gravity or springs close the flaps to seal the room.

5. What is the difference between a "vacuum breaker" and a "pressure relief valve"?

Technically, a vacuum breaker only lets air in to break a vacuum. A pressure relief valve usually works two ways (bi-directional), allowing air both in (to break vacuum) and out (to relieve overpressure). Our valves are dual-action for maximum safety.

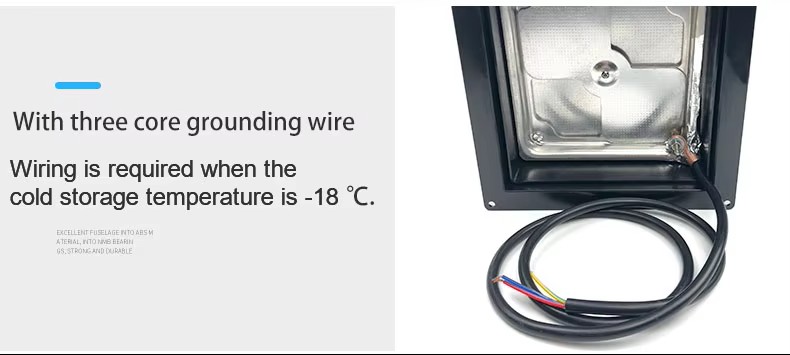

6. Why are these valves heated?

In freezer applications, moisture in the air passing through the valve can instantly freeze, sealing the mechanical flaps shut. Our valves utilize integrated electrical heating elements (PTC) to keep the rim and flaps frost-free, ensuring they function correctly at all times.

7. How many pressure relief valves do I need?

The general rule of thumb for standard storage is one valve per 100 cubic meters ($m^3$) of volume. However, for blast freezers or rooms with rapid temperature changes, you may need one valve per 50 cubic meters.

8. How do I calculate the airflow requirement for my room?

You need to consider the maximum rate of temperature change (cool-down rate). A standard formula is: $Flow (L/min) = Volume (m^3) \times \Delta T (Temperature Drop per min) \times 3.66$. If you are unsure, contact our engineering team with your room dimensions and refrigeration capacity.

9. Can I just use a bigger valve instead of multiple small ones?

Yes, high-flow industrial valves (like our Titan Series) can often replace multiple smaller standard valves. This reduces the number of holes you need to cut in your panels.

10. What wall thickness does the valve fit?

Our standard valves feature a telescopic (adjustable) sleeve that fits wall panels ranging from 60mm to 150mm. For thicker insulation (up to 250mm), we offer extension kits.

11. Is this valve suitable for "Blast Freezers"?

Yes. Blast freezers experience very rapid pressure drops. You must select our "High-Flow" or "Industrial" models for blast freezers to handle the large volume of air exchange required quickly.

12. Where should the pressure relief valve be installed?

The ideal location is on a wall, away from the direct airflow of the evaporator fans and away from the door. It should be easily accessible for maintenance.

13. Can I install the valve on the ceiling?

Yes, but you must ensure the model you choose is rated for ceiling mounting. Ceiling installation requires careful waterproofing on the external side to prevent melted snow or dust from entering the mechanism.

14. At what height should the valve be mounted?

We recommend installing it at eye level or slightly higher (approx. 1.5m to 1.8m from the floor) to prevent damage from forklifts or pallets, while remaining accessible for inspection.

15. How do I wire the heater cable?

The valve comes with a 3-core cable (Live, Neutral, Earth). It should be connected to a continuous power supply (not the light switch). It is best practice to wire it to a separate breaker so the heater stays on even if the refrigeration unit is turned off for service.

16. Do I need to use silicone sealant during installation?

Our valves come with rubber gaskets. However, for a perfect airtight seal in industrial environments, applying a bead of cold-resistant silicone sealant around the external flange is highly recommended.

17. Can I retrofit this valve into an existing cold room?

Absolutely. You simply need to cut the appropriate diameter hole (usually 102mm or 4 inches) using a hole saw, insert the valve, and wire it up. It is a quick upgrade for older rooms.

18. What voltage are the valves?

Standard models are 220V-240V AC (50/60Hz). We also stock 110V versions for markets like the US and Japan. Please specify your voltage when ordering.

19. What is the power consumption?

They are very energy efficient. Standard models consume between 8W and 25W, depending on the size and ambient temperature. The PTC heaters regulate their own power usage.

20. What is the operating temperature range?

Our valves are designed to operate in internal temperatures from -40°C to +50°C (-40°F to 122°F).

21. Are the valves fire-rated?

The housing is made from self-extinguishing ABS plastic (UL94 V-0 rating). While the material is fire-resistant, please check your local building codes for specific fire-stop requirements.

22. Is the heating element replaceable?

On our Industrial (Titan) series, the heating element can be replaced. On smaller, sealed commercial units, the heater is molded into the body, so the unit must be replaced if the heater fails.

23. Why is my cold room door still hard to open?

If you have a valve installed but the door is sticking, the valve may be:

-

Too small for the room volume.

-

Blocked by ice (heater failure).

-

Blocked by boxes or pallets inside the room.

Check if the heater is warm to the touch.

24. The valve is making a whistling noise. Is this bad?

A slight "whoosh" sound when the door opens or closes is normal—it means the valve is working and air is moving! However, a continuous high-pitched whistle might indicate the valve is undersized and air is struggling to force its way through.

25. How do I know if the heater is working?

Touch the internal faceplate of the valve carefully. It should feel slightly warm to the touch compared to the surrounding cold wall. If it is cold and covered in frost, the heater or power supply is faulty.

26. How often should I clean the valve?

Inspect the valve every 6 months. Ensure the louvers/flaps move freely and are not obstructed by dust or ice. Wipe down with a damp cloth; do not use harsh chemicals.

27. Do you offer stainless steel versions?

Yes. For food processing plants, pharmaceutical storage, or highly corrosive environments (like fish storage), we offer Grade 304 Stainless Steel pressure relief ports.

28. What is the warranty period?

We offer a 12-month standard warranty on all electrical components and a 2-year warranty on the structural housing.

29. Can you customize the length of the pipe?

Yes. For extra-thick walls (over 200mm), we can provide custom-length PVC extension tubes.

30. Are spare parts available?

We stock spare gaskets, external louvers, and replacement heater cables for our industrial range. Contact our sales team for a parts list.