How To Choose Sliding Or Swing Cold Storage Doors

Choosing the right door for your cold storage facility isn’t just about "closing the gap." It’s a critical decision that impacts your energy bill, your workflow efficiency, and the lifespan of your refrigeration equipment. In the world of industrial cooling, we primarily see two heavyweights: Swing (Hinged) Doors and Sliding Doors.

This guide will break down everything you need to know to make the right choice for your facility in 2026.

1. The Basics: Defining the Contenders

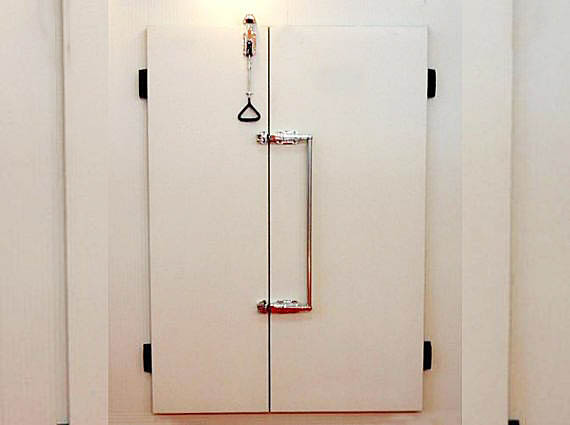

Swing Cold Storage Doors (Hinged Doors)

Swing doors operate exactly like the front door of a house but on a much beefier, industrial scale. They are mounted on hinges and swing outward or inward to open.

-

Best For: Small walk-in coolers, personnel access, and areas with limited wall space.

-

The "Vibe": Simple, reliable, and traditional.

Sliding Cold Storage Doors

These doors operate on a track system, sliding horizontally along the wall to reveal the opening. They can be manual or automated.

-

Best For: Large warehouses, forklift traffic, and high-volume loading docks.

-

The "Vibe": High-tech, space-saving, and efficient.

2.The Definitive Guide to Cold Storage Doors

Sliding vs. Swing: Choosing the Right Thermal Barrier for Your Facility

In the precision-driven world of cold chain logistics, a door is not merely an entrance—it is a critical component of a thermal management system. For facility managers and business owners, the choice between a Sliding Cold Storage Door and a Swing (Hinged) Door can determine the long-term viability of your refrigeration system.

1. The Engineering of Thermal Separation

The primary function of any cold storage door is to minimize heat gain, which can be modeled by the simplified heat transfer equation:

Where:

-

Q is the heat leakage.

-

U is the thermal transmittance of the door material.

-

A is the surface area.

-

T is the temperature difference between the refrigerated space and the ambient environment.

While U and A are often fixed by the door’s construction, the operational efficiency (how long the door stays open) is where the choice between Sliding and Swing doors makes the most impact.

2. Swing Doors: The Reliable Standard

Swing doors are the "workhorses" of small-scale cold storage. They operate on heavy-duty hinges and swing open 90 to 180 degrees.

The Advantages:

-

Superior Gasket Compression: Because the door closes into the frame, the pressure is evenly distributed across the gaskets, providing a near-perfect airtight seal.

-

Cost-Efficiency: They are significantly cheaper to install and maintain due to fewer moving mechanical parts.

-

Installation Flexibility: Ideal for facilities where wall space to the left or right of the opening is obstructed by structural columns or piping.

The Trade-offs:

-

The "Swept Area" Problem: You cannot store goods within the radius of the door's swing. In a 500-square-meter warehouse, the "dead space" created by multiple swing doors can reduce storage capacity by up to 5%.

-

Air Turbulence: The physical "swinging" action creates a bellows effect, pushing cold air out and pulling warm, moist air in every time the door is cycled.

3. Sliding Doors: The High-Throughput Powerhouse

Sliding doors move horizontally on a track system. In 2026, most industrial sliding doors utilize "cam-action" tracks that drop the door inward and downward upon closing to ensure a tight seal.

The Advantages:

-

Operational Velocity: Sliding doors are easily automated. High-speed sliding variants can open at rates of 1.0 to 1.5 meters per second, drastically reducing the time the "thermal envelope" is broken.

-

Safety in High Traffic: In environments where forklifts and pallet jacks are constant, sliding doors are safer. They don't "swing out" into traffic lanes, reducing the risk of collisions.

-

Space Optimization: Since they slide parallel to the wall, you can utilize every centimeter of floor space right up to the door frame.

The Trade-offs:

-

Wall Space Requirements: You must have a clear section of wall (wider than the door itself) for the door to retract into.

-

Maintenance Complexity: The tracks, rollers, and drive motors require a scheduled maintenance program to prevent "derailing" or motor burnout.

4. How to Guide Your Selection

To determine which door fits your specific needs, we recommend the "Three T" Framework:

I. Traffic (Volume & Type)

If your door cycles more than 30 times per hour, or if you use forklifts, a Sliding Door is the only logical choice. The automation prevents workers from "leaving the door open" while they fetch pallets, which is the #1 cause of evaporator icing.

II. Temperature (The T Factor)

For deep-freeze applications (e.g., $-25°C$ or lower), the energy loss during a slow manual swing-open cycle is catastrophic. Automated sliding doors with heated perimeters prevent frost buildup and keep the T stable.

III. Territory (Available Space)

Measure your Clear Opening Width (COW). If you have a COW of 2 meters but only 1 meter of wall space to the side, you are restricted to a Swing Door or a Bi-Parting Sliding Door.

5. Summary for the Customer

Choosing a door is a balance between Capital Expenditure (CapEx) and Operating Expense (OpEx). A swing door saves you money today (CapEx), but an automated sliding door saves you money every month on your electricity bill and equipment wear-and-tear (OpEx).

Decision Rule:

-

Choose Swing for personnel access and low-frequency small storage.

-

Choose Sliding for any environment where efficiency, speed, and floor space are the priority.

3. Conclusion

In 2026, the trend is moving toward Automated Sliding Doors for almost all industrial applications due to the rising costs of energy and the need for high-speed logistics. However, for the "back-of-house" personnel access, the humble Swing Door remains the king of cost-effective reliability.

Pro Tip: Regardless of the door type you choose, always invest in high-quality PVC Strip Curtains. They act as a secondary barrier that keeps the cold air in even when the main door is wide open.

Post time:Sep-25-2020