Choose Air Curtains or PVC Strip Curtains?The Ultimate Cold Storage Showdown

In the world of cold chain logistics and food processing, the doorway is your biggest liability. Every time a warehouse door opens, cold air escapes, and warm, humid air rushes in. This leads to skyrocketing energy bills, ice buildup, and spoiled inventory.

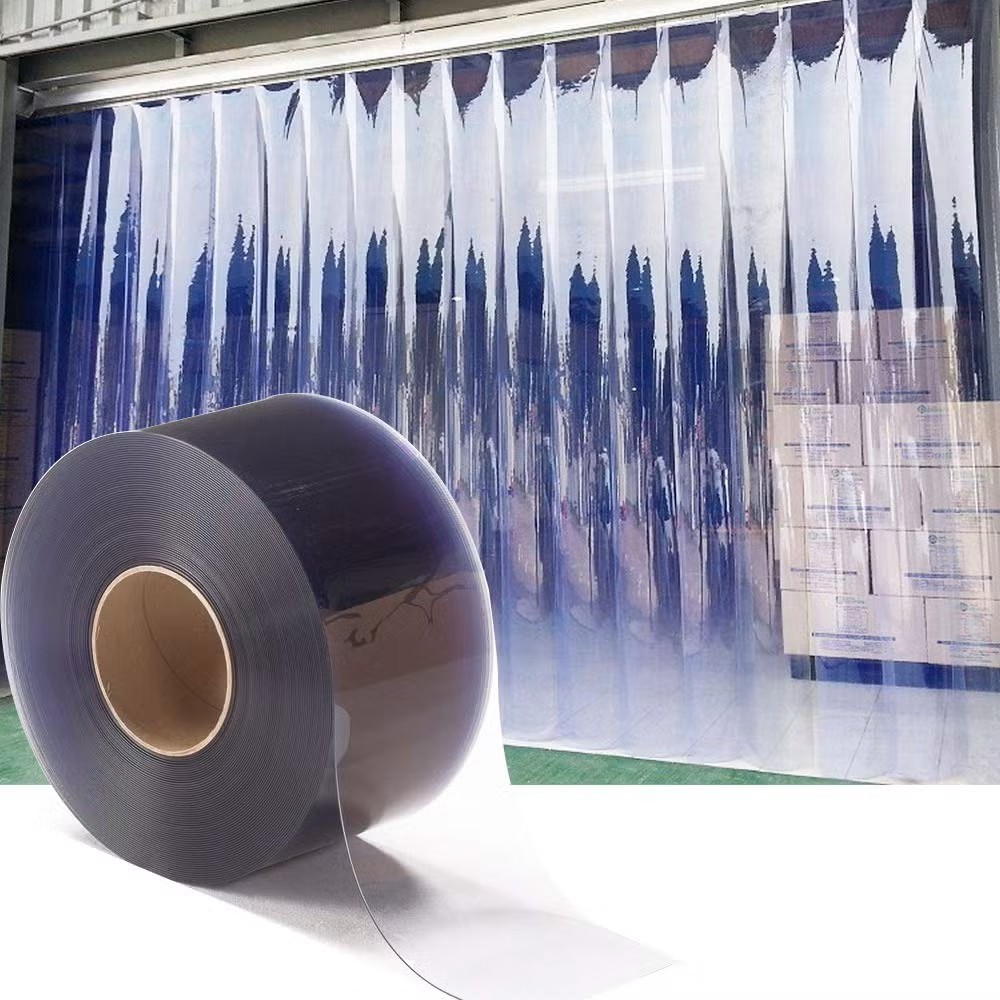

For decades, facility managers have relied on PVC Strip Curtains to solve this problem. However, as technology advances, Industrial Air Curtains have emerged as a superior alternative.

But is the upgrade worth the investment? In this comprehensive comparison, we analyze the pros and cons of both systems to help you choose the right solution for your cold storage facility.

1. Energy Efficiency & Thermal Sealing

The PVC Strip Reality:

When first installed, PVC strips provide a solid physical barrier. However, their efficiency drops rapidly. As forklifts pass through, the strips swing, creating gaps where air can escape. Over time, strips warp, crack, or fail to overlap correctly, rendering them ineffective at holding temperature.

The Air Curtain Advantage:

An air curtain creates an invisible wall of high-velocity air. Because it is a non-physical barrier, it provides a 100% seal across the entire width of the door, regardless of traffic. Modern cold storage air curtains use precision airflow to separate thermal zones effectively, often retaining up to 80-90% of the conditioned air inside the freezer, drastically reducing compressor workload.

Winner: Air Curtains (For consistent, long-term efficiency).

2. Hygiene and Contamination Control

The PVC Strip Reality:

In food processing environments, PVC curtains can be a hygiene nightmare. They collect grease, dust, and moisture. Because people and products physically touch the strips to pass through, cross-contamination is a serious risk. Cleaning them is labor-intensive, and dirty strips can lead to health inspection failures.

The Air Curtain Advantage:

Air curtains offer a touchless solution. There is no physical contact between the barrier and the food products or staff. Furthermore, the downward force of the air acts as an active shield, physically repelling flying insects, dust, and fumes from entering the clean zone. This makes them the preferred choice for HACCP-compliant facilities.

Winner: Air Curtains (Hands down for food safety).

3. Workflow and Safety

The PVC Strip Reality:

PVC strips inevitably obstruct visibility. Over time, they become scratched, cloudy, and opaque (frosting up in freezers). This creates a significant safety hazard for forklift drivers who cannot see what is on the other side of the door, leading to collisions and accidents. Additionally, drivers must slow down to push through the heavy plastic, slowing down logistics operations.

The Air Curtain Advantage:

Because the barrier is invisible, visibility is perfect. Forklift drivers can see oncoming traffic or pedestrians clearly, reducing workplace accidents. There is no physical resistance, meaning traffic flows without interruption. This seamless access speeds up loading and unloading times significantly.

Winner: Air Curtains (Best for safety and speed).

4. Maintenance and Durability

The PVC Strip Reality:

While cheap to buy initially, PVC strips have a high "cost of ownership." In a busy warehouse, strips are frequently ripped off or damaged by pallets and forklifts. They require constant replacement and maintenance to remain effective.

The Air Curtain Advantage:

An industrial air curtain is a "install and forget" solution. With durable stainless steel casings (often IP54 rated) and robust motors, they are designed to last for years with minimal maintenance (usually just an occasional filter clean or fan wipe-down). There are no parts to replace weekly or monthly.

Winner: Air Curtains (Lowest long-term maintenance).

At a Glance: The Comparison Table

Feature

PVC Strip Curtains

Cold Storage Air Curtains

Initial Cost

Low

Moderate / High

Long-Term ROI

Low (High replacement costs)

High (Energy savings pay for it)

Hygiene

Low (Collects dirt/bacteria)

High (Touchless & Repels pests)

Visibility/Safety

Poor (Scratches & fogs up)

Excellent (Invisible barrier)

Traffic Flow

Obstructive (Must push through)

Unobstructed (Free flow)

Maintenance

Frequent (Strip replacement)

Minimal (Periodic cleaning)

The Verdict: Which Should You Choose?

Choose PVC Strip Curtains if:

-

You have an extremely low initial budget.

-

The doorway has very low traffic (opened only a few times a day).

-

Hygiene and visibility are not critical priorities.

Choose Cold Storage Air Curtains if:

-

Energy savings are a priority for your business.

-

You have high traffic (forklifts, pallet jacks) entering and exiting.

-

You operate a food processing or pharmaceutical facility requiring strict hygiene.

-

You want to eliminate the recurring cost and hassle of replacing broken plastic strips.

Ready to Upgrade?

Post time:Sep-25-2020